Discover the latest best practices and risk considerations for maintaining the stability of deadweight primary standards in force calibration laboratories. This article by Henry Zumbrun (Morehouse Instrument Company), published in Cal Lab: The International Journal of Metrology, explains the hierarchy of force calibration standards, the unmatched long-term stability of deadweight machines, and the empirical evidence supporting calibration intervals of 20–30 years or more. It also outlines compliance strategies for ISO/IEC 17025, ILAC G24, and provides practical recommendations for laboratory maintenance and risk mitigation.

For a comprehensive overview and actionable guidance on deadweight primary standards in force calibration laboratories, download the full article here

Want to see force setup and other videos? Click here.

The 333-page book covers various topics essential for understanding and improving force calibration processes. Readers will find in-depth discussions on the fundamentals of force measurement, detailed explanations of various calibration methods, and guidance on selecting the right equipment. The comprehensive content includes:

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Over the years, many of us at Morehouse have been asked what value one should use for Load Cell Reliability when a system is new.

You may think: “I need a load cell reliability number for my uncertainty budget. What should I use?”

The answer is variable as it depends on several factors.

One critical factor is determining how stable the load cell system needs to be to meet a person's measurement uncertainty requirements.

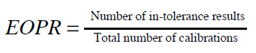

Is 89 % EOPR acceptable with 95 % Confidence, or is 95 % End of Period Reliability (EOPR) the goal?

The other reaction we often receive is, “No one does that because there are too many variables.”

Load cell reliability will depend on the complete system and its use.

The use would include anything that could influence the results.

Force is mechanical, such as using different adapters, cables, thread engagement, overloading the load cell, the meter used, and the number of loading cycles.

So, after being asked numerous times, we decided to tackle the question, "What should I expect for stability with year-to-year annual calibrations?"

We started by finding enough samples to meet the 95 % Confidence Interval criteria, with 95 % End of Period Reliability, which seemed daunting.

Download the full paper here.

To be notified when new content is developed, please follow Morehouse on LinkedIn.

Recommended Compression and Tension Adapters for Force Calibration: We buy a great force standard, we demonstrate metrological traceability, & we make a force measurement. Without the proper compression and tension adapters, the errors can be over 10 times that of the specification. This article discusses the importance of compression and tension adapters and provides solutions for better calibrations using the appropriate compression and tension adapters. For more information on adapters, click here.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Portable Force Machine Solves Several Measurement Management Headaches. This paper examines several “bad” measurement practices, such as using multiple technicians to calibrate instruments (including hand-held dynamometers). Such practices include using a free-floating cable and stacking weights to calibrate a cable tensiometer. We discuss how a portable force calibration machine can be used to improve efficiency and solve several measurement challenges. Click Here to read our portable force calibration machine paper.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Deadweight Force Standard Stability: Proven Accuracy That Lasts Decades

Deadweight force standards are universally recognized as the most accurate method for calibrating force-measuring instruments. These systems deliver exceptional performance, achieving expanded uncertainties as low as 0.001% of the applied force—far surpassing the capabilities of lever, hydraulic, or universal testing machines. What sets deadweight systems apart is not just their precision, but their unparalleled long-term stability.

Extensive studies conducted by national metrology institutes such as NIST (National Institute of Standards and Technology) and NPL (National Physical Laboratory, UK) have confirmed that deadweight force standards experience virtually no measurable drift in mass over 20–30 years or more. These findings are reinforced by internal calibration comparisons, mass re-verifications, and international interlaboratory studies showing that, when properly maintained, deadweight systems retain their original performance characteristics within parts-per-million precision.

This level of deadweight force standard stability allows laboratories to confidently extend calibration intervals, aligning with international quality frameworks like ISO/IEC 17025 and ILAC G24. In fact, excessive recalibration or disassembly of these machines can introduce more risk than benefit—potentially compromising measurement integrity through mechanical wear, contamination, or transport-induced damage.

The accompanying technical paper explores this stability in depth, providing real-world data, design recommendations, and maintenance strategies. It emphasizes best practices such as in-situ checks, statistical process control, and the importance of avoiding unnecessary teardown procedures. From selecting corrosion-resistant materials to implementing advanced automation and environmental monitoring, every detail contributes to maintaining world-class metrological performance.

If long-term reliability, minimal measurement uncertainty, and traceability to the SI are critical to your application, deadweight force standards remain the gold standard in calibration. This paper explains why—and how to keep them that way.

The Morehouse paper on Deadweight Force Standard Stability highlights key research from several documents and justifies setting long calibration intervals without disassembling deadweight force machines to recalibrate the weights.

Download your copy of Deadweight Force Standard Stability and Best Practices.

Want to see force setup and other videos? Click here.

Metrology and the Consequences of Bad Measurement Decisions by Scott Mimbs

This paper was initially published in Test Magazine and is being shared as one of the essential documents we believe anyone making measurements should read.

In the simplest terms, measurements are made to support decisions.

Measurement data support decisions to:

• Establish research or investigative fact;

• Establish scientific or legal facts;

• Accept or reject a product;

• Rework or complete a design;

• Take corrective action or withhold it;

• Continue or stop a process (including a space launch).

The measurement is unnecessary if the data from measurements are not used in decision-making or establishing facts (including scientific research).

# Measurement Decisions

Scott Mimbs has written many papers, and one of our favorites discussing the importance of definitions can be found here.

Want to read more on Decision Rules? Check out our blog.

Henry Zumbrun, President of Morehouse Instrument Company, explores the complex world of decision rules in metrology with an unconventional twist. His article, "The Force of Decision Rules: Applying Specific and Global Risk to Star Wars," featured in the January issue of Quality Magazine, uses the Star Wars saga to shed light on the subject.

In this article, Zumbrun uses examples from the first Star Wars movie, Episode IV: A New Hope, to demystify decision rules and make them more understandable for everyone. He focuses on some specific and global risk examples. Readers will gain a comprehensive understanding of the fundamental principles by the article's conclusion. Download the article here.

If you enjoyed this content, check out our LinkedIn page and YouTube channel for more helpful posts and videos.

Converting a mV/V Load Cell Signal into Engineering Units is a common need in the industry. This paper discusses the pros and cons of how meters handle Converting a mV/V Load Cell Signal into Engineering Units. The paper discusses significant error sources and best practices for using an indicator with a mV/V signal, and we offer guidance on some indicators that can convert that signal into engineering units.

So, how low can my load cell go? Like the Limbo, everything has a point where going lower is impossible. In this article, "How Low Can My Load Cell Go?" Morehouse Instrument Company President Henry Zumbrun provides three things to consider regarding measurement uncertainty when you ask how low your load cell can go. The article appeared in Cal Lab: the International Journal of Metrology (January, February, March 2024). Read it here.

Read other articles and blogs by Henry Zumbrun here.

If you enjoyed this content, check out our LinkedIn page and YouTube channel for more helpful posts and videos.

Measurement Bias: What can happen when we use an accuracy specification and assume all the measurements are centered to the specification limits?

Not correcting for Measurement Bias is a typical problem in the metrology community, where many papers assume a centered process or Measurement and that any known Measurement Bias has been corrected.

The Morehouse technical paper on Measurement Bias examines what happens if we fail to correct Measurement Bias at the bench level and gives examples based using Specific Risk. Specific Risk is the probability that an accepted item is non-conforming or that a rejected item does conform. This risk is based on measurements of a single item.

In general terms, Specific Risk is dependent on a single probability function and can be referred to as Probability of Conformance from the customer’s point of view.

Not correcting for Measurement Bias matters because when a known bias is ignored, meaning not corrected or not included in the Statement of Measurement Uncertainty on the Calibration Certificate, measurement traceability may not be fully achieved, and all subsequent measurements are suspect.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

An Introduction to the Differences Between ASTM E74 and ISO 376, the Two Most Recognized Force Standards: The differences Between ASTM E74 and ISO 376 can be confusing. Morehouse has been performing both ASTM E74 and ISO 376 calibrations for more than fifteen years. We have been calibrating in accordance with the ASTM E74 standard since its introduction in 1974 and performing ISO 376 calibrations since sometime in early 2000. Until recently, we assumed that the rest of the world and the force community knew that the standards were completely different and that either standard could not be substituted for another. This paper explains those differences in more detail.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

The new dimension to resolution paper. This paper stresses the importance of considering the unit under test resolution in a measurement uncertainty budget. Download our new dimension to resolution paper here.

If you enjoyed this content, check out our LinkedIn and YouTube channels for more helpful posts and videos.

A paper on the Common Measurement Errors in Weighing. Anyone calibrating or using crane scales, load cells, dynamometers, truck scales, and aircraft scales will benefit from learning about the various common errors in weighing. Download our Common Errors in Weighing paper here.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Analyzing the Effects of Reducing the Ending Zero vs Ignoring the Trailing Zero on Measurement Instruments Used for Force Calibration (2014): ASTM E74 Method A and Method B—for the treatment of reducing the ending zero. Method A defines the deflection calculation as the difference between the deflection at an applied force and the initial reading at zero force. The article was written by Henry Zumbrun for Cal Lab Magazine 2014.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Potential Measurement Errors in Force Calibration: This article covers the most common errors one must know when making calibrating force instrumentation.

Potential Measurement Errors in Force Calibration in published test magazine from Oct-Nov 2015 issue.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

What is measurement risk? Measurement decision risk is the probability that an incorrect decision will result from a measurement. Are you telling your customers instrument passes without considering measurement uncertainty? If taken to court, are your measurement defensible? This paper examines the proper way to make statements of compliance. Download our Measurement Risk paper here.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Have trouble understanding Uncertainty Propagation for Force measurement and how to put together a budget? This paper examines all of the components required to put together a full calibration and measurement capability (CMC) reviewed by Accreditation Bodies for your scope. This Uncertainty Propagation guide to calculating force measurement uncertainties & was published in Cal Lab magazine. Download our Uncertainty Propagation for Force paper here.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Load cell dual-range calibration errors happen when a load cell is not loaded to full capacity. The molecules inside the load cell do not react potentially causing an increased error. What you need to know about molecule excitement decline and dual-range calibrations. Article from Test Magazine May 2016 issue.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Why a 4 to 1 TUR is Not Enough: The Importance of Analyzing the Probability of False Accept Risk: Several organizations and publications reference or insist on maintaining a 4 to 1 TUR (Test Uncertainty Ratio) without understanding the level of risk that they may be subjecting themselves to. The general thought is that if the lab performing the calibrations has standards at least four times better than what they are calibrating, everything will be good. This paper discusses TUR, PFA Risk, and why the location of the measurement matters. We will discuss two managed risk guard banding methods (5 & 6) in the ANSI/NCSL Z540.3 Handbook. We will show that a 4 to 1 TUR is insufficient and can result in a 50 % risk. Check out our blog post on TUR here.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

The Design, Development, and Commissioning of a 2kNm Torque Standard Machine for Highly Accurate Torque Calibrations: This is a 2007 article detailing the world's second-most accurate torque machine at Morehouse. Here at Morehouse, we provide torque calibration from 1Nm to 2kNm. For more details on our torque calibration service, click here.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

3 Bar vs 2 Bar Universal Calibrating Machines Comparison Test: This paper describes the difference between these two designs. The paper compares the repeatability and reproducibility characteristics and examines if there is a significant difference in the performance and measurement uncertainty between the two designs.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Aircraft Scale Calibration and Measurement Capability; Scale Calibration for several aircraft scales requires one to replicate the footprint of the tire. Not doing so may produce out-of-tolerance conditions or a very high bias. Information on our aircraft scale calibration services can be found here.

This paper will describe our calibration process, including the calculations of our Calibration and Measurement Capability (CMC), as it appears on our scope of accreditation.

If you enjoyed this content, check out our LinkedIn and YouTube channel for more helpful posts and videos.