The 3 Important Changes to ISO 9001 Compliance and What This Means for Force and Torque Instrumentation

The 3 Key Changes to ISO 9001 Compliance and What this Means for Force and Torque Instrumentation are discussed in detail in this article. What you need to know about documented procedures, preventative actions, and top management.

Change 1:

1. Documented Procedures are No Longer Required. - Documented procedures are helpful regarding how to calibrate equipment and may be useful to you. However, you are no longer required to keep a physical manual on-site. There is going to be a lot more risk when equipment is not used properly or written procedures are not documented and followed.

There is an alternative to some of this by verifying the proper measurements via calibration, repeatability and reproducibility studies, and proficiency testing. In addition, calibration data (records) will still be required (ISO9001 Clause 7.1.5.1 (b) are maintained to ensure their continuing fitness for their purpose.

The organization shall retain appropriate documented information as evidence for the purpose of the monitoring and measurement resources.).

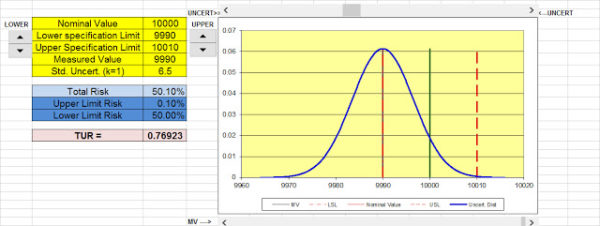

The image above is a normal distribution showing a 50.1 % probability of calling the measurement good when it is not. The uncertainty of the measurement must be considered when evaluating risk.

Change 2:

- Preventative Action Clause No Longer Exists - Everything has been focused on risk-based thinking. This requires the organization to start taking action for the following:

In avoiding risk, both the consumer and producer should be considered. Measurement Uncertainty and the resolution of the Unit being tested should be considered when making statements of compliance. (ISO 9001 Clause 9.1.3 Analysis and Evaluation: The organization shall analyze and evaluate appropriate data and information arising from monitoring and measurement.

The results of the analysis shall be used to evaluate;

- a) conformity of products and services;

- e) the effectiveness of actions taken to address risks and opportunities;

Also, see ISO 9001 Clause 10.2 Nonconformity and Corrective action

Eliminating the source of risk - this is where SPC and good verification standards, as shown above, may help.

Changing the likelihood or consequences of risk.

Making an informed decision regarding the elimination of risk versus managing the risk

Change 3:

- Top Management is now held more responsible than before - The expectation is for Top Management to start risk-based thinking and may bear the responsibility for failures. Remember that device that should have been calibrated and was not or its calibration interval was extended to save money? If there was no risk-based evidence to support the decision, top management may be accountable. The use of Control Charts (SPC) is one of the tools to manage risk and calibration intervals.

The 3 Key Changes to ISO 9001 Compliance and What This Means for Force and Torque Instrumentation - Conclusion

Morehouse offers an SPC workshop that focuses on mitigating and managing risk in calibration. Our full training schedule can be found here.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment. We challenge the "just calibrate it" mentality by educating our customers on what matters, and what causes significant errors, and focus on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.

# iso 9001