Loose Bolts & Torque Control

Imagine if one of the one hundred and fifty-plus car engine bolts is under-torqued; it loosens over time and eventually destroys the engine.

What if the bolts are under-torqued in an airplane assembly and become loose mid-flight?

What if those bolts were to the exit door, which blew off mid-flight, and the cabin lost pressure at 10 km in the air?

This article examines the importance of controlling the tightening of a fastener so that things do not come loose.

We will examine the application of torque, discuss what loose bolts could do and some causes, and examine the pros and cons of several torque wrench types.

Loose Bolts: How Torque is Determined

The connection (joint) is made up of different pieces which are attached and held together.

The device (fastener) that holds the pieces together must be designed to be stronger than the total of all loads incurred (including all operational and environmental factors).

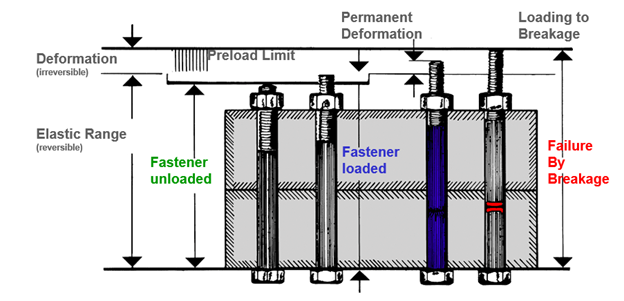

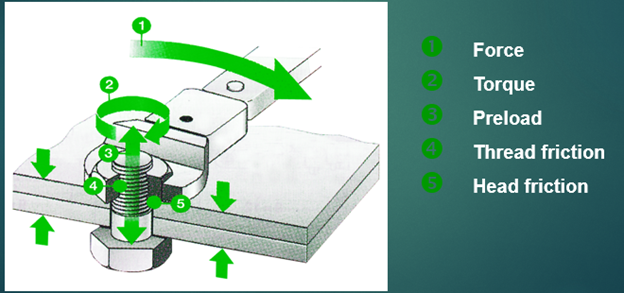

The tightening of the fastener creates a "clamping force."

The fastener is dimensioned and preloaded so that all forces acting to separate the connection are overcome.

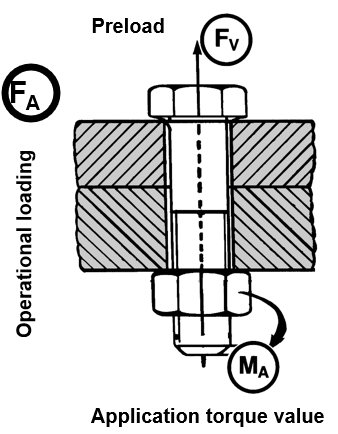

To reach a desired torque value, enough force must be applied:

To overcome the friction induced by turning the fastener against its components (nut, threads, spring washer, etc.) and the attached and clamped materials.

Load the fastener and materials connected to a value inside their elastic limits.

The object of a threaded fastener is to clamp parts together with a tension greater than the external forces tending to separate them.

When appropriately torqued, the bolt remains under constant stress and is immune from fatigue.

Loose Bolts: The Importance of Torque Control

Figure 4 Loose Bolts: Vibration Can Loosen the Bolt

If the torque is not applied correctly and the tension on the bolt torque is too low, varying loads will act upon the bolt and fail.

Proper torque control during the tightening of bolts ensures that they are securely fastened.

Loose bolts can loosen over time from constant vibrations.

This can compromise the assembly's structural integrity and lead to potential failures.

Bolts are often used in structures and machinery where their integrity is critical.

If bolts are not tightened to the specified torque, the structural components may not be securely connected, leading to instability and a higher risk of failure.

What are the Industry Specific Causes of Loose Bolts

Various studies and reports within automotive, aerospace, and construction industries have consistently identified improper torque as a common cause of fastener-related issues.

These issues can range from minor performance problems to catastrophic failures.

Maintenance Incidents:

In maintenance and reliability reports, incidents related to fasteners are often listed among the top causes of equipment failures.

Failure to tighten fasteners to the correct torque specifications may result in unexpected downtime, increased maintenance costs, and potential safety hazards.

Aerospace Industry:

In the aerospace industry, where precision and safety are paramount, accidents have been attributed to improperly torqued fasteners.

These incidents underscore the critical importance of accurate torque control in this sector.

Automotive Industry:

In the automotive sector, loose or inadequately torqued fasteners can lead to vehicle malfunctions, accidents, and recalls.

Wheel lug nuts, for example, are critical components where improper torque can have severe consequences.

We wrote an article specifically on this as it happened to one of us. That article can be found here.

Structural Failures:

Improperly torqued fasteners in construction and civil engineering applications can contribute to structural failures.

This can compromise the safety and stability of buildings, bridges, and other infrastructure.

Oil and Gas Industry:

In the oil and gas industry, where equipment operates in harsh conditions, improperly torqued fasteners can lead to leaks, equipment damage, and unplanned shutdowns, affecting overall operational efficiency.

Loose Bolts Industry Stats from UK CAA MORs in the 1990's

These statistics are older, though relevant, as many of these issues happen today.

They arise from a lack of training and employee disengagement.

Issues such as:

- incorrect installation of components

- fitting of wrong parts

- electrical wiring discrepancies (including cross-connections)

- loose objects (tools, etc) left in aircraft

- inadequate lubrication

- cowling, access panels, and fairings not secured

- landing gear ground lock pins not removed before departure

Which is broken down further in the James Reason Report:

- Fastenings undone/ incomplete (22%)

- Items left locked/ pins not removed (13%)

- Caps loose or missing (11%)

- Items left loose or disconnected (10%)

- Items missing (10%)

- Tools/spare fastenings not removed (10%)

- Lack of lubrication (7%)

- Panels left off (3%)

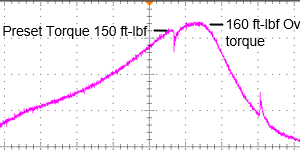

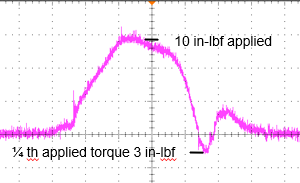

Loose Bolts: Back Torque with Some Wrenches

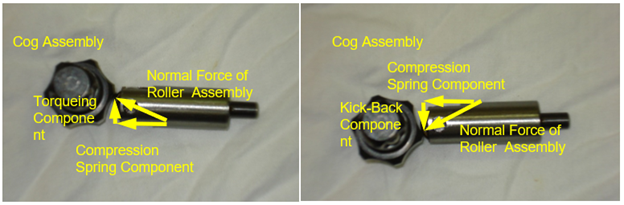

What is back torque?

Back torque is when the energy of a click-type wrench comes back in the opposite direction and loosens a bolt.

The back-torque or kickback issue is with a specific "Bi-Directional Ratcheting" type of torque wrenches.

More specifically, back-torque is when the setpoint of the compression spring is overcome, the roller assembly climbs over the cog, and a load component is created in the direction of the torque being applied.

As the roller assembly comes off the backside of the cog, it naturally creates a kickback load component in the reverse direction of the torque being applied.

Some Pros of click-type torque wrenches:

- Provide consistent results.

- Reduce operator error reading and interpreting scale.

- Get the right wrench from the kit and use it.

- Independent verification is rarely needed.

Figure 5 Loose Bolts: Can a Torque Wrench Loosen the Bolt? The Cog Assembly naturally creates a "kickback" torque component.

Some Cons of click-type torque wrenches:

- There is a tendency to over-torque a fastener by 15-20 percent using these tools.

- Humans cannot react quickly enough when the click mechanism is tripped.

Note: Not all click-type wrenches produce this kickback.

The best recommendation is to ask the manufacturer if the wrenches are impact-free or have any kickback.

Loose Bolts: Conclusion

The significance of torque control in fastener applications cannot be overstated, as highlighted throughout this exploration.

The potential consequences of loose bolts extend beyond mere inconvenience, encompassing catastrophic failures, safety hazards, and structural compromises across various industries.

Proper torque application is not just about tightening bolts; it is a critical aspect of ensuring the integrity and reliability of assemblies.

As examined, the clamping force generated by correctly torqued fasteners is designed to withstand external forces and environmental factors, providing stability and immunity from fatigue.

Torque control is particularly important in automotive, aerospace, construction, and oil and gas industries, where precision, safety, and operational efficiency are paramount.

Instances of loose bolts have been identified as significant contributors to equipment failures, accidents, and unplanned shutdowns.

Furthermore, the exploration of torque wrench types, such as click-type wrenches and the potential back-torque issues, emphasizes the need for careful consideration in selecting the right tools.

While these tools offer consistency and reduce operator error, awareness of their limitations, such as the tendency to over-torque and the potential for kickback, is crucial.

Controlling torque is not merely a technical detail but a fundamental practice that safeguards against a cascade of repercussions.

As industries evolve and technology advances, the commitment to precise torque application remains a cornerstone in ensuring structures and machinery's longevity, safety, and reliability.

The journey from understanding the clamping force to exploring the intricacies of torque wrenches underscores torque control's critical role in the seamless functioning of our engineered world.

-Henry Zumbrun, President of Morehouse Instrument Company

About Morehouse Instrument Company

Companies worldwide rely on Morehouse for accuracy and speed. The company turns around equipment in 7-10 business days so customers can return to work quickly and save money.

Morehouse Instrument Company, a trusted and accredited provider of force and torque measurement services for over 100 years, offers measurement uncertainties 10-50 times lower than the competition.

Morehouse helps commercial labs, government labs, and other organizations lower their measurement risk by lowering equipment uncertainties for torque and force measurement. Contact Morehouse at info@mhforce.com .

More Information about Morehouse

We believe in changing how people think about force and torque calibration in everything we do.

This includes setting expectations on load cell reliability and challenging the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition.

We turn around your equipment in 7-10 business days so you can return to work quickly, saving you money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff.

Our YouTube channel has videos on various force and torque calibration topics here.