Torque Calibration: Why Torque Control is Important - Intro

At Morehouse we teach torque classes, give webinars on torque, and perform torque calibrations on reference standards. We strive to create a safer world by helping companies improve their force and torque measurements.

However, we are not immune to the safety hazards that can result from improper torque control. Below is a picture of what happens when too much or too little torque is applied to the bolts on a car.

Figure 1: Aftermath of Not Applying the Proper Torque to a Fastener

My son took his 2013 Santa Fe in for a recall because 151,205 cars were likely affected by a defect with the braking system. The issue was that brake fluid could leak into the ABS module, possibly resulting in an electrical short, resulting in an increased risk for an engine fire. Likely, an issue that you might want to be fixed before a long drive on a holiday weekend, right?

The car dealership told us the brake pads are worn enough to warrant replacement. What followed is an unfortunate series of events. My son picked the car up, and is told to expect abnormal driving and noises for the next 150 miles as they are normal. He heads to Virginia and ends up losing a wheel on the highway.

Figure 2: Front Wheel that Popped Off

Thankfully, no one is hurt in the next series of events. The wheel came off, crossed the median, and my son drove on three wheels while trying to break before he hits something that would cause even more damage. He stopped about five feet shy of the next obstacle.

As a parent, I cannot tell you the mixed emotions I was feeling when I got a call from my son. Many questions raced through my mind:

- We teach courses to prevent these things from happening. How could this happen?

- Why did it happen? Are the torque tools calibrated?

- Did the mechanic know they failed to properly put on the wheel?

- Did they check the torque?

- Did they just tighten one wheel with the special lock nut and forget the rest?

- How did they not notice the issue on the test drive after the service?

- Did they test-drive it?

- Do they have their torque wrenches calibrated?

- Do they have the proper training?

- Have we at Morehouse made an impact in the metrology world?

- How can we use our knowledge to save lives?

- How can we ensure that a mechanic knows how to properly torque the nuts on the bolts?

- Is my son shaken up that he does not want to drive?

- How about his mental wellbeing after this type of accident?

I posted a story on Facebook and was horrified by the responses. Many people commented that they knew someone or they personally had the same type of thing happen to them. In one case the mechanic forgot to tighten the bolts, and the mechanic was immediately terminated for incompetence.

It was eye-opening for me to see the frequency at which these incidents occur. How would you react if you were driving and a tire popped off? What if you were driving with your family and a tire came bouncing down the road toward your car?

As you can imagine, I called the dealership regarding the issue. They asked me to email pictures and said a manager would call me back in four days. Four days is too long for a bad torque wrench or improperly trained mechanic to be installing breaks on someone else's car. The dealer ended up paying all the cost, but did not do an investigation. Unfortunately, that is the world we live in.

I am using this example to explain torque calibration issues, and hope that others share it. This could prevent future incidents and save someone’s life or the headache of this happening to them.

What is torque?

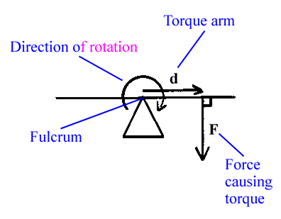

Torque, also called moment or moment of force, is the tendency of a force to rotate an object about an axis, fulcrum, or pivot. Just as a force is a push or a pull, a torque can be thought of as a twist. Torque is derived from the SI units of length, mass, and time.

Figure 3: Torque is Force times Length

Those that know me know I stress that torque is force times length. It is not FT-lbs or M-N. It is funny how no one ever says M-N. Torque is N-m, or lbf-ft.

Figure 4: Expression of Torque

How Torque Value is Determined

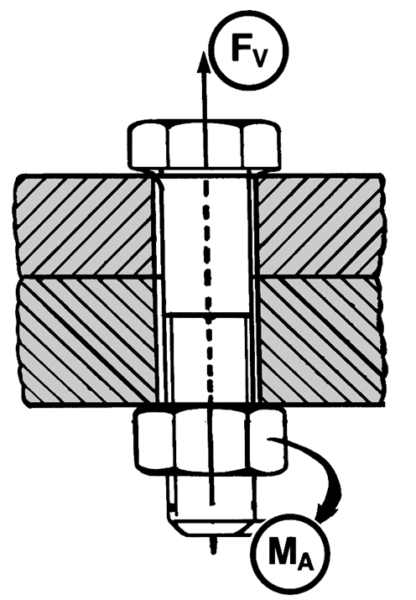

A connection, or joint is made up of different pieces which are attached and held together. The device, or fastener which holds the pieces together must be designed to be stronger than the total of all loads incurred, including all operational and environmental factors. The tightening of the fastener creates a clamping force.

Figure 5: Determining Torque

The fastener is dimensioned and preloaded so that all forces acting to separate the connection are overcome. The object of a threaded fastener is to clamp parts together with a tension greater than the external forces tending to separate them. When the bolt is torqued correctly it remains under constant stress and is immune from fatigue. When it is not torqued properly, bad things happen!

Bolts and Over-Torquing

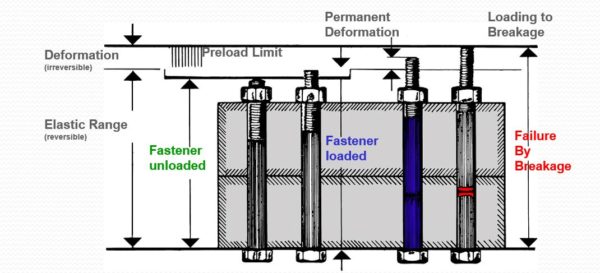

Look at this picture to see what can happen when bolts are over torqued.

Figure 6: What Happens when Bolts are Over-Torqued

Deformation means the bolts will never be the same again. It may also mean the connections, such as the hub, are damaged. This is not a simple or inexpensive mistake to make. If the bolts are tensioned too high, they could fail at any time.

When wheel nuts are over-torqued, studs can become stretched and eventually break. The rims can also crack because of over-torquing. Finally, over-torquing causes an excess force to be placed on the remaining wheel nuts and studs, which weakens them and causes them to break, resulting in a detached wheel.

Dealer liability claims are common. Why does over-torquing still happen?

The issue is typically seen in two scenarios:

- Incidents where tires have come detached from a moving vehicle.

- Situations where a vehicle’s safety system is not working correctly.

Both issues are serious, and the consequences can result in accidents, injuries, or even death. For example, a wheel flying off on the highway is a serious safety concern. We can all agree that it should not happen, yet if you Google search “dealership over torqued my lug nuts” there are many examples.

One good example I use in training shows a dragster owned by Jeff Nihil. The pit crew over-torqued the bolts on the left exhaust manifold. The bolts then failed, the manifold popped off, and 4000bhp of exhaust gas launched the car in the air at over 200mph!

Not Applying Enough Torque

Figure 7: H20 Pump Pulley Bolt about to come off

We discussed applying too much torque. How about what happens when not enough torque is applied? If the torque is not applied correctly and the tension on the bolt torque is too low, varying loads will act upon the bolt, and it will fail. Typically, the nut will loosen.

In the scenario with my son’s tire, a torque too low or a loose nut would cause the tire to wobble and eventually come off. It is likely that two to three would be missing the nut but intact, and maybe others would bend, or one or two may come clean off from the forces, assuming the nuts held for a bit. It would look a lot different if all but one bolt had sheared and broken off.

This type of incident happens quite a bit. On July 25, 2011, Honda Motor Co. said it would recall a combined 50,122 units in the Stream minivan, the Civic sedan, and the Crossroad sport utility vehicle to repair the bolts that fasten the water pump pulley to the engine, free of charge. They said the bolts might lose tension or fracture, causing the drive belt, which runs both the alternator and the water pump to circulate coolant water to come off the pulley.

Another example is the 760,000 Toyota RAV4s that were recalled from 2006 to 2011. Toyota said that if the nuts on the rear suspension arms of these vehicles aren’t appropriately tightened during a wheel alignment service, the arms may come loose or separate.

What needs to happen with my son's car situation?

The dealer should have done a root cause investigation to find out if they over-torqued or simply left the wheels loose. They need better measures in place to ensure this does not continue to happen. The dealership should undergo a safety audit. Training should happen to ensure they do not put other lives at risk. They should own the problem and pay all costs. Unfortunately, they only covered the cost.

What needs to happen in the industry?

My original Facebook post about this situation revealed to me that improper torquing is pretty standard. After doing some research, I learned that improper or unchecked torquing of wheel nuts is the most common cause for claims where wheels have come detached from moving vehicles.

The torque wrenches should be calibrated by reputable labs that calculate measurement uncertainty properly and can demonstrate the proper traceability. We need to treat torque tools and training more seriously, and every mechanic should be trained like they are in the military.

One Marine said that as a mechanic in the Marines, he had to make sure he used torque wrenches properly. The tool room had a logbook to track what tools were being used on what trucks. The mechanics were told that if someone died because of neglect, they could be thrown in jail.

This emphasizes the severity of not following the right procedure and knowing how to apply the proper torque. I believe it is time for dealerships to take more accountability and make us all safer.

Torque Calibration: Why Torque Control is Important - Outro

We want to spread awareness! Please share and keep sharing until more dealerships implement the proper safety practices. You can also learn more about our Torque Calibration services.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. We challenge the "just calibrate it" mentality by educating our customers on what matters, what causes significant errors, and focus on reducing them.

Morehouse makes simple-to-use calibration products. We build fantastic force equipment that is plumb, level, square, rigid, and provide unparalleled calibration service with less than two-week lead times.

Contact us at 717-843-0081 to speak to a live person or email info@mhforce.com for more information.