Recommendations for Specifying ASTM E74 Calibration Services

Recommendations for Specifying ASTM E74 Calibration Services. This document is intended to help properly specify what you may need for ISO/IEC 17025 accredited ASTM E74 calibrations to ensure you are getting exactly what you need:

Verification of the Calibration Supplier Can meet the Requirement.

Reviewing many accredited laboratory Scope of Accreditation and certificates of calibration from the accredited laboratories, Morehouse has witnessed many laboratories not following the guidelines set forth in the ASTM E74 standard. ) Also witnessed were secondary accredited laboratories claiming measurement uncertainties lower than the calibration service provider who calibrated their standard load cell and much more.

Purchase Order (PO) Description Template

- The calibration laboratory shall be accredited in accordance with the:

requirements of ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories.

- The calibration laboratory’s Scope of Accreditation to ISO/IEC 17025 shall:

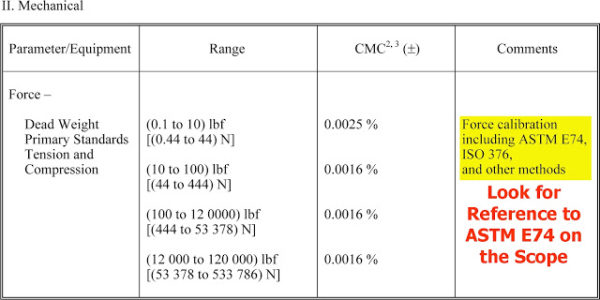

encompass the calibration parameter of Force (e.g., ASTM E74, Tension and/or Compression 100 to 1000K lbf with a CMC uncertainty parameter of XXX or better). The example below clearly shows the lab can perform calibration in accordance with ASTM E74, ISO 376, and other methods.

Note: If the device is to be calibrated in both Ascending and Descending modes, ask the calibration provider if they have their standards calibrated in both modes. We wrote a blog on ascending and descending measurement errors. The blog can be found here. Many scopes do not contain this information, and the provider must be asked if they had their instruments calibrated in the descending mode.

- The accreditation of a testing or calibration laboratory shall be issued by an Accreditation Body (AB) that is:

an ILAC Mutual Recognition Arrangement (MRA) Signatory (e.g., A2LA, IAS, ANAB, PJLA) and that operates in accordance with ISO/IEC 17011, General requirements for accreditation bodies accrediting conformity assessment bodies.

- The testing (or calibration) report or certificate must be endorsed by the:

Recognized Accreditation Body’s symbol (or must otherwise indicate accreditation status by a

recognized Accreditation Body).

| AB symbol with Morehouse Certificate # |

- Specify the range required by the customer:

(e.g. 1000 to 10,000 lbf)

Note: Some laboratories offer a multi-range calibration for one load cell. If required specify the range(s) on the PO.

- Specify if your load cell is required to be calibrated:

in tension, compression, or both.

- Specify if the load cell is to be calibrated:

ascending, descending, or both.

- Specify if:

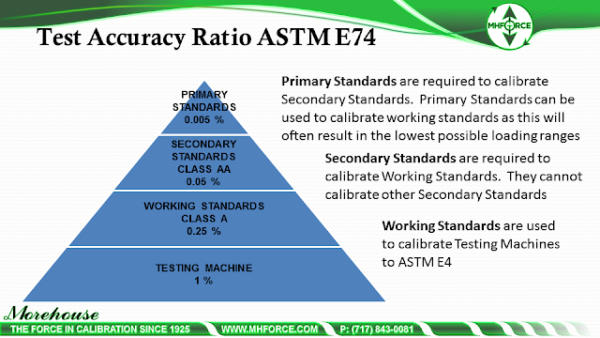

a class AA or A verified range of forces is required. If Class AA if required, calibration can only be done by labs with Primary Standards. See the picture below for an explanation.

- Specify calibration intervals:

Calibrations in accordance with ASTM E74-13 and later are found in section 11.2

Decide if you want the calibration laboratory to enter the ASTM E74 due dates on the certificate and labels. If the device does not meet the stability criteria set forth in ASTM, let the calibration laboratory know the time interval to ensure it meets the criteria found below.

Rationale :

Bullet Point #1 stipulates that the testing and calibration be accredited in accordance with ISO/IEC 17025.

Bullet Point #2 requires that the test or calibration services requested be listed on the service provider’s Scope of Accreditation.

Note: If this requirement is not stated, the laboratory could claim that it is ISO/IEC 17025 “compliant” (i.e., self-declared) even though the provider is not actually accredited for the test, calibration, or service requested. This is not to imply that a self-declared “accredited” organization is not technically competent or in compliance, but it should not be necessary for the customer to vet (assess) that organization if they are accredited by a recognized Accreditation Body.

Bullet Point #3 contains two important stipulations: [1] that the laboratory used be accredited to ISO/IEC

17025, and [2] that the Accreditation Body (AB) be under an ILAC Mutual Recognition Arrangement (MRA) signatory. Without this Bullet Point, the laboratory could be accredited by an AB that has inadequate or misleading credentials.

Note: There are ABs in the USA that claim to be in compliance with ISO/IEC 17011 [so-called “self-declared ISO/IEC 17011 compliant ABs”]. Some ABs in the United States offer what equates to "mail-order" accreditation services and never visit the lab to ensure implementation of ISO/IEC 17025 or other requirements or to verify their staff's technical competence. Holding an ILAC MRA signatory status indicates that the AB has been periodically peer-evaluated against the requirements of ISO/IEC 17011. This peer evaluation process ensures that ABs meet strict international requirements, thus affording a high level of confidence in their assessment process when accrediting laboratories.

Bullet Point #4 is required to ensure that the test or calibration performed was consistent with the providing organization’s accredited criteria.

Note: Many organizations offer multiple levels of service at varying costs. Furthermore, the lab may meet the requirements for the first three elements of the template but deliver a service not covered under their accredited services.

Bullet Point #5,6,7and 8 are required to identify to the calibration service provider the required:

- Force Range(s)

- Mode(s)

- Your planned use of the load cell

- Loading Range Class

Many calibration service providers offer ASTM E 74 services, but not all of them can offer everything listed in Bullet Points 5 – 8, thus your requirements need to be communicated to the calibration service provider.

Bullet Point #9

ISO/IEC 17025 5.10.4.4 states:

A calibration certificate (or calibration label) shall not contain any recommendation on the calibration interval except where this has been agreed with the customer. This requirement may be superseded by legal regulations.

ASTM E74 states:

- Time Interval Between Calibrations and Stability

Criteria

11.1 All force-measuring instruments and systems shall meet the range, accuracy, resolution, and stability requirements of this standard and shall be suitable for their intended use.

11.2 The calibration intervals for force-measuring instruments and systems used as secondary force standards or for the verification of force indication of testing machines shall be calibrated at intervals not exceeding two years after the demonstration of stability supporting the adopted recalibration interval. New devices shall be calibrated at an interval not exceeding 1 year to determine stability per 11.2.1.

11.2.1 Force measuring instruments shall demonstrate changes in the calibration values over the range of use during

the recalibration interval of less than 0.032% of reading for force measuring instruments and systems used over the Class AA loading range and less than 0.16% of reading for those instruments and systems used over the Class A loading range. See Note 16.

11.2.2 Devices not meeting the stability criteria of 11.2.1 shall be recalibrated at intervals that shall ensure the stability criteria are not exceeded during the recalibration interval. See Note 16.

NOTE 16—The above stability criteria provide minimum requirements for establishing calibration intervals for force-measuring Instruments and systems used as secondary force standards and those used for the verification of the force indication of testing machines. Users specifying the percentage limit of errors other than Class AA or Class A should determine stability criteria appropriate to the instruments employed. For secondary force standards, it is recommended that cross-checking be performed at periodic intervals using other standards to help ensure that standards are performing as expected.

Recommendations for Specifying ASTM E74 Calibration - Conclusion

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment. We challenge the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors, and focus on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.

# Recommendations for Specifying ASTM E74 Calibration