Metrological Traceability for Force

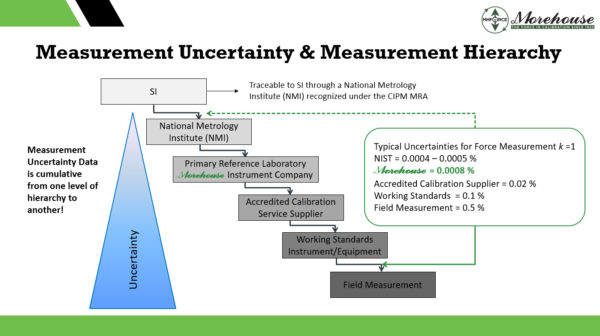

Metrological Traceability for Force - Metrological Traceability: Property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty.

This article will define each level of the measurement hierarchy as it relates to measurement uncertainty for force-measuring devices and then compare the expanded uncertainty between a Primary Reference Laboratory and an Accredited Calibration Service Supplier.

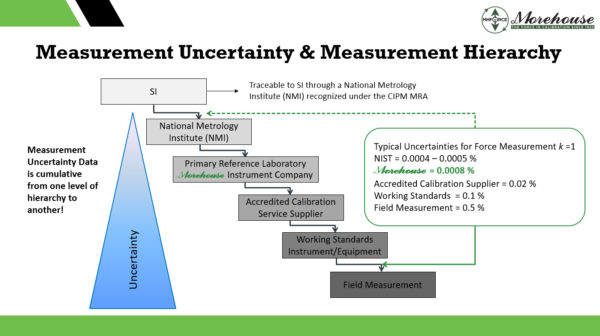

| Picture of Metrological Traceability - Measurement Hierarchy For Force Calibration |

Metrological Traceability for Force

Force = mass (Kilogram) x Acceleration (metre per second squared) BIPM

The international prototype of the kilogram, an artifact made of platinum-iridium, is kept at the BIPM under the conditions specified by the 1st CGPM in 1889 when it sanctioned the prototype and declared.

The kilogram is the unit of mass; it is equal to the mass of the international prototype of the kilogram.

National Metrology Institute (NMI)

In the United States, the National Institute of Standards and Technology (NIST) is the designated NMI

NIST uses dead weight primary standards known to be within 0.0004 % of applied up to 4.4 MN or 1,000,000 LBF

Primary Reference Laboratories

Primary Reference Labs use dead weight Primary Standards, usually calibrated by N.I.S.T. as the reference standard. Morehouse Instrument Company uses dead weight primary standards calibrated directly by NIST up to 533 kN or 120,000 LBF known to be within 0.008 % of applied.

Morehouse Calibration and Measuring Capabilities (CMC) as reported on our scope of accreditation is 0.0016 % to 0.002 % of applied using dead weight primary standards. (Note 0.0016 % is for K=2)

Accredited Calibration Service Supplier

Accredited Calibration Suppliers use secondary standards (those calibrated by primary standards) Typically these standards are capable of measuring forces to within 0.02 % of applied typically for k=1. When working with several standards such as ASTM E74, ISO 376, and others, these labs are often required to have their instrumentation calibrated by deadweight primary standards. If you are not working to ASTM, ISO 376, or other standards requiring calibration dead weight primary standards you will need to determine the appropriate uncertainty needed to calibrate other Measuring and Test Equipment (MT&E)

Working standards and certified reference materials used in commerce and industry have a traceable relationship to the secondary and primary standards. This is the category where you need to determine the appropriate uncertainty needed to calibrate your Measuring and Test Equipment (MT&E). If you are accredited and using dynamometers, force gauges, load cells, or other MT&E to make critical measurements, you will want to use a calibration laboratory with Calibration and Measuring Capabilities low enough so that the Probability of False Accept (PFA) is low enough to ensure you are using these devices within the stated tolerances.

Note: The risk of incorrectly declaring a device as in-tolerance (

false-accept risk) is dependent upon several factors. Those factors include the specified tolerance limit, guard band, the

calibration process uncertainty, etc..,

These are typically the material testing machines used for tensile, compression, fatigue, impact, rheology, structural, materials, or a range of other force applications.

What does this mean as far as the Uncertainty of Your Standards?

Metrological Traceability - Your Measurement Uncertainty is directly affected by the standards used to perform the calibration.

When you calculate measurement uncertainties in accordance with ISO “Guide to the Expression of Uncertainty in Measurement” (GUM)1, A2LA R205, and ILAC P-14 as required by ISO/IEC 17025 guidelines you will need to consider the following:

Reference Standard Uncertainty

Reference Standard Stability

You can use these standard contributors to derive your CMC (Calibration and Measurement Capability) which is then reported to your customer, among other things

Let's examine CMC and what the reference lab's CMC does to the calibration results

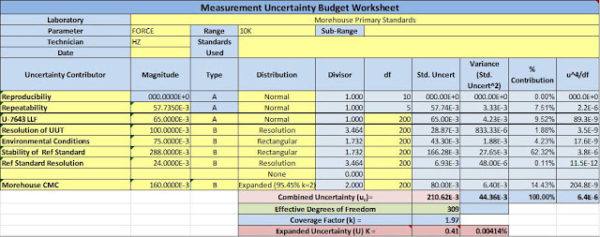

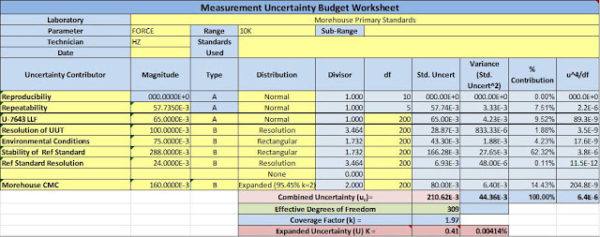

Primary Calibration Laboratory CMC

Morehouse Primary Standard as the Reference (CMC 0.0016 % for K=2 or 0.16 LBF @ 10K)

Morehouse CMC is 14.43 % of the Total Expanded Uncertainty (U)

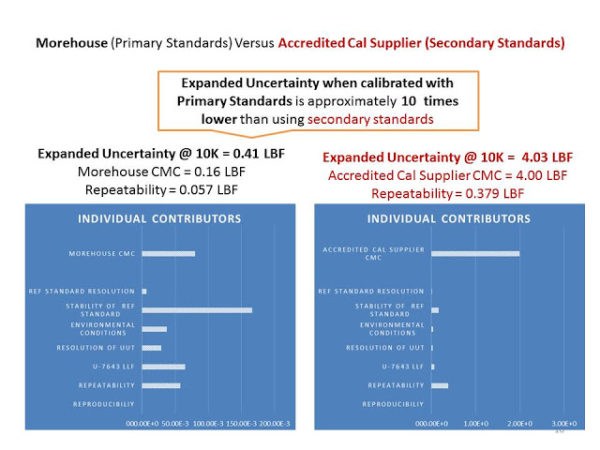

Expanded Uncertainty @ 10K = 0.41 LBF

Morehouse CMC = 0.16 LBF Repeatability = 0.057 LBF

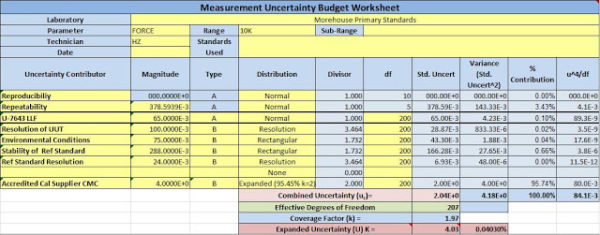

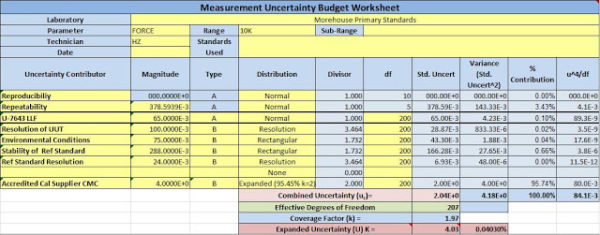

Accredited Calibration Supplier

Accredited Calibration Supplier with Secondary Standards as the Reference (CMC 0.04 % for K=2 or 4 LBF)

Accredited Calibration Supplier 95.74 % of the Total Expanded Uncertainty (U)

Expanded Uncertainty @ 10K = 4.03 LBF

Accredited Cal Supplier CMC = 4.00 LBF, Repeatability = 0.379 LBF

Metrological Traceability for Force - Conclusion

When selecting a calibration laboratory, it is important to evaluate your tolerances and the Calibration and Measurement Capability Uncertainty Parameters (CMCs) of your calibration supplier. Lower uncertainties typically equate to more accurate measurements, less risk, long-term cost savings, and consumer confidence.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment. We challenge the "just calibrate it" mentality by educating our customers on what matters, and what causes significant errors, and focus on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.

#Metrological Traceability for Force #Metrological Traceability