How to Calibrate Button Load Cells and Achieve Solid Results

How to Calibrate Button Load Cells - Intro

Anyone who has tried calibrating button-type load cells knows they do not repeat well in the rotation. The sensitivity to off-axis or side-loading conditions is quite high. High enough that 0.1 % of misalignment will produce a rather large cosine error. The error can sometimes be as large as 10 % of the rated output. We typically find this error between one and two percent in well-aligned deadweight machines. This blog will show that using the proper adapters can drastically improve the performance of button load cells.

How to calibrate button load cells Problem:

It's nearly impossible to get results to agree within 0.5 % when repositioning a button load cell.

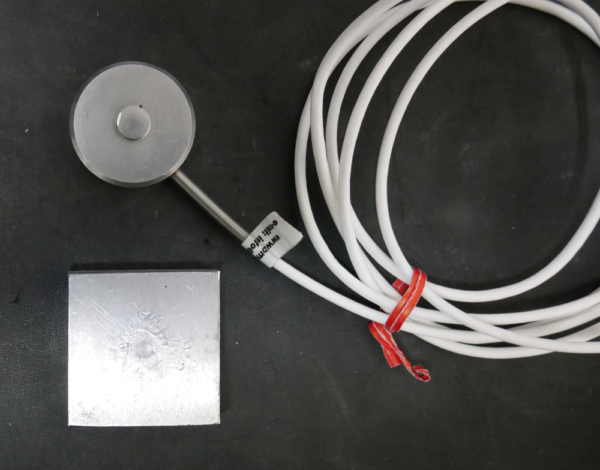

With traditional calibration methods shown in Figure 1 below, getting reproducible results on button-type load cells is nearly impossible.

Figure 1. The traditional method of calibrating a button load cell. This is a compression-type pad.

How to calibrate button load cells Test Plan:

Conduct a test on the same button load cell with traditional calibration methods versus using Morehouse custom adapters.

A test was conducted as shown in Figure 2.

Figure 2: Test pictures and data using traditional versus Morehouse Adapters

The above data shows a 525 % improvement in rotation using Morehouse Adapters. The reproducibility error went from 1.045 % to 0.199 %. It is worth mentioning that most button load cell systems cannot achieve better than 0.25 % of full scale even with the proper adapters. We have seen some specifications where the end-user is expecting 0.1 % of full scale or better. Without the proper adapters, 1 percent of full scale is nearly impossible to achieve.

Proper testing would involve putting the unit back into the machine and demonstrating agreement between the tests. With the Morehouse Adapters, reproducibility of better than 0.25 % is possible as demonstrated. To achieve these results the button load cell must not be damaged or have wear patterns. Those cells with wear patterns are going to have much larger errors. Morehouse adapters will also improve those results, but our adapters will not turn a worn button load cell with a 5-10 % error into a cell with an error of better than 0.5 % of full scale. In general, we see improvements with a magnitude of 2 - 10 times better when using the proper adapters.

How to calibrate button load cells and achieve good results - conclusion

Using Morehouse custom adapters to align the button type load cell significantly reduces misalignment error.

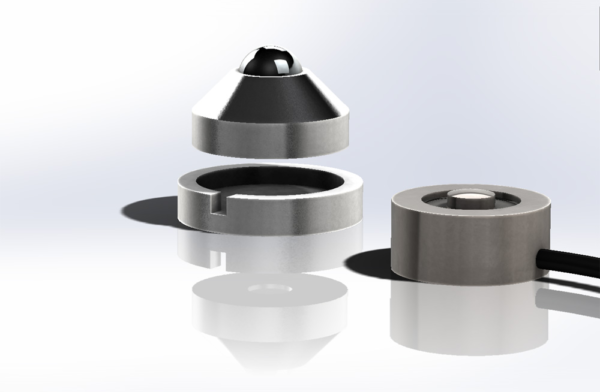

Figure 3 shows Morehouse Adapters for calibrating button load cells.

Figure 3. Morehouse Adapters

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment. We teach people how to calibrate button load cells properly. We challenge the "just calibrate it" mentality by educating our customers on what matters, and what causes significant errors, and focus on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.

#How to calibrate button load cells