Cable Tensiometer Calibration can be riddled with issues

Maintaining precise cable tension is crucial across various industries, including engineering, construction, aerospace, and manufacturing. Cable tensiometers serve as indispensable instruments for measuring and monitoring this cable tension. However, the calibration of cable tensiometers is riddled with problems.

Clear communication between calibration labs and end users is essential to guarantee that calibrations accurately reflect how equipment is used in real-world situations. This is especially crucial because different calibration methods can sometimes lead to discrepancies of over 20 %, potentially casting doubt on the equipment's functionality.

This paper will examine the essential aspects of successful cable tensiometer calibration: selecting the right equipment, implementing the optimal process, and understanding the end-user's requirements. We will delve into three crucial factors that can significantly impact calibration accuracy:

- Cable Length: The impact of different cable lengths used during calibration.

- Calibration Method: Analysis of various calibration techniques and their influence on results.

- Cable Type: How variations in cable types (e.g., GAC vs. SSAC) affect calibration outcomes.

We aim to initiate a conversation and encourage best practices for better alignment between calibration practices and real-world requirements, enhancing the reliability of cable-dependent systems across diverse industries.

Learning objectives

By the end of this reading, you will be able to:

- Identify three key factors that can significantly impact the accuracy of cable tensiometer calibration.

- Compare and contrast different methods used for calibrating cable tensiometers.

- Analyze the impact of cable length and type on calibration results.

- Evaluate the importance of understanding end-user practices for selecting appropriate calibration methods.

- Recognize the potential discrepancies between current calibration practices and real-world cable usage.

- Appreciate the need for improved communication between calibration laboratories and end-users.

What is a Cable Tensiometer?

Cable tensiometers are devices used to measure the tension or force in cables, wires, and ropes. They typically feature a load sensor or gauge that provides real-time tension readings.

Calibrating a cable tensiometer involves knowing the proper requirements, having the right equipment, and the right processes.

How to Calibrate Cable Tensiometers: The Right Requirements

What is needed to accomplish this task? Does cable tensiometer calibration affect the type and length of cable used?

Several variables can influence the readings of the cable tensiometer. The standard variables are.

- The Length of the Cable.

- The Method Used for Calibration.

- The Type of Cable GAC versus SSAC.

To ensure meaningful data, one must determine the appropriate test method that best replicates how your customers use the equipment. Are they clamping a tensioned cable or adjusting the tension based on the calibration chart?

How to Calibrate Cable Tensiometers: The Right Equipment

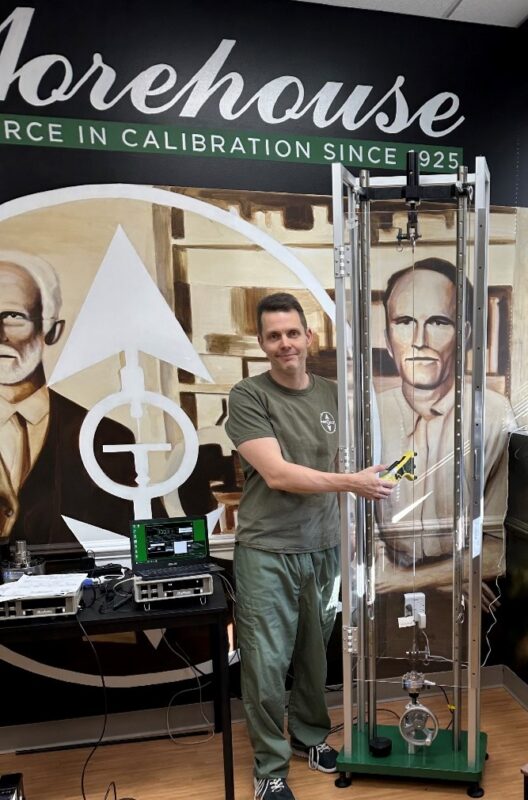

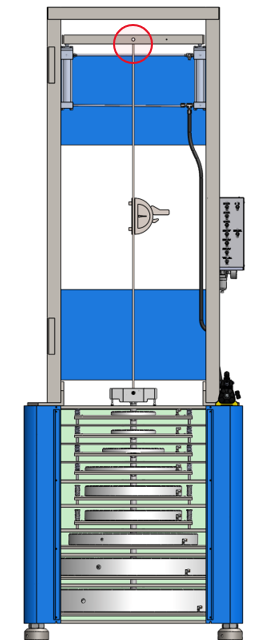

In the above image, Henry Zumbrun uses a Morehouse Cable Tensiometer Machine (PCM-2MD-T1) and a 500 lbf Morehouse load cell reference standard that was calibrated using the ASTM E74 standard using deadweight primary standards known to be better than 0.002 % of applied force.

Note: The Expanded Measurement Uncertainty for the Morehouse Cable Tensiometer typically falls between 0.02 % and 0.04 % of applied forces.

The right equipment may also consist of cables of at least 3 feet or greater free from defects. That means the cable should lie flat and not have any bends or kinks. Some systems use cables that are 18 – 24 inches, and these shorter cables can lead to different results.

It is essential to read the manufacturer's recommendations, which often include recommended cable lengths and types.

The Morehouse system incorporates several key features to ensure accurate and reliable tensiometer calibration:

- Minimized Strain: A load cell positioned at the base eliminates the influence of any extra strain caused by hanging and clamping the tensiometer.

- Precise Frame: The machine's frame is meticulously designed to be plumb, level, square, and rigid, minimizing torsion and offering exceptional control during calibration.

- Versatile Calibration: The Morehouse system allows for two calibration methods: clamping and adjusting the tension, pre-loading the cable to a specific value, and clamping. It can accommodate cables up to 5 feet long and generate tension forces as high as 2,000 pounds-force (lbf).

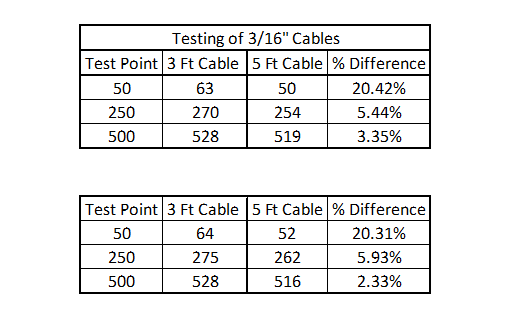

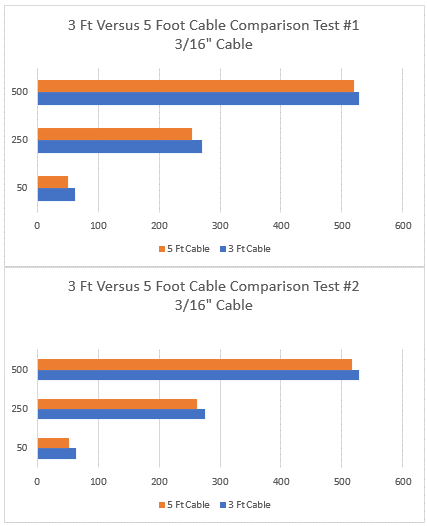

The overall results for the "clamp and adjust" technique using different digital tensiometers show a similar trend, which makes sense. The higher the tested value, the lower the percentage difference between cables.

We can draw an analogy between cables and springs. When subjected to the same force, a longer cable, like a spring with double the length, will experience greater stretching. Consequently, compared to a shorter cable stretched by the same amount, a longer cable may exhibit a smaller relative increase in tension.

Think about a rubber band and how a thinner or longer one will stretch more than its thicker or shorter counterpart. A cable acts the same. Steel is much less stretchy, so the length changes are much less.

Additionally, we are only varying the cable length from what is generally considered a minimum to a longer length. Depending on the thickness of the cable, those who use cables from 18 inches to 24 inches in length will likely observe higher differences compared with 60-inch cables.

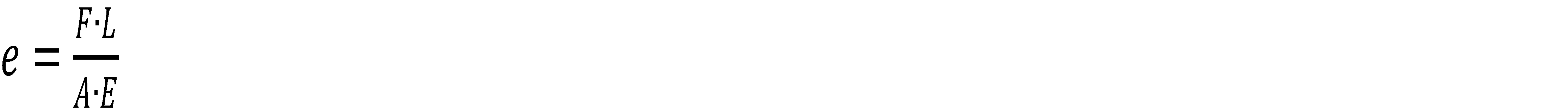

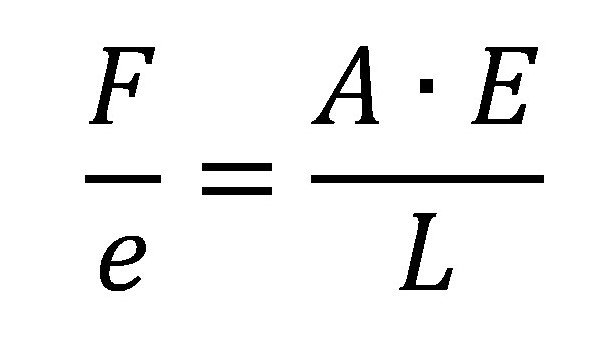

If you were testing a solid piece of wire, the formula for elongation of a uniform cross-section in tension summarizes that force (F), length (L), width (area, A), and material (modulus of elasticity, E) are all related to elongation (e):

Rearranging gives:

F/e is the spring rate, which is the amount of force (e.g., lb.) per displacement (e.g., in). So 50lb/in means if you apply 100 lb., it will stretch 2 inches. Thinking about the cable, we can see that increasing area increases the spring rate, increasing material stiffness (modulus of elasticity) increases the spring rate, and increasing length decreases the spring rate. A lower spring rate means less change in force (tension) when applying the tensiometer.

Cables used for tensiometers are stranded wire and are much more complicated. The same basic principles apply, though there is also torsion and bending, which isn't entirely negligible for the measurement.

The Machine and Method Used for Calibration

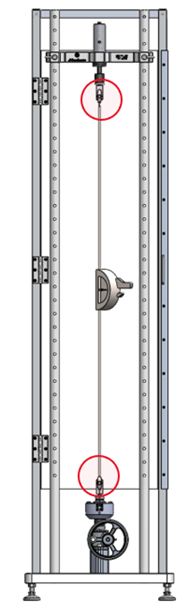

There are two common calibration machines used to calibrate cable tensiometers:

- Deadweight calibration with one fixed point: The hanging deadweight avoids introducing additional tension, as clamping the cable does not affect the measured force.

- Machine calibration with two fixed points: Clamping the cable in this method shortens the distance between two fixed points, introducing additional tension.

Calibration Using Deadweight.

The Morehouse 774000 Tensiometer Deadweight Calibrator revolutionized calibration processes. A fixed point (shown in the red circle) eliminates the need to secure cables to beams and manually hang weights. This design prioritizes safety and simplifies the calibration technician's work. The operator secures the cable and selects desired weights up to 2000 lbf.

The design allows the weights to hang in the air, so we call this a machine with one fixed point, as clamping the cable will not create any additional force.

The Morehouse Cable Tensiometer Machine (PCM-2MD-T1), with two fixed points (shown in the red circles), also eliminates the need to secure cables to beams and manually hang weights. One of these points is attached to a more solid fixture in a load cell connected to a jack(bottom), and the other is connected at the top where there is a spring. The spring can either be set up to be very rigid or have some flex.

However, this machine uses two fixed points to apply tension to the cable, meaning that when we use a tensiometer to clamp the cable, we create additional tension. It is the way the cable tensiometers work. They have a system that clamps the cable and thus tries to shorten the length between the two fixed points.

Using the Morehouse PCM-2MD-T1, we can evaluate two different methods. One of the methods simulates that close to that of deadweight.

Method 1 Clamp the tensiometer and adjust the force. This method is when the force is applied close to the desired reading, the cable is clamped, and then the force on the cable is adjusted back to the nominal value. In this case, we might load to 460 lbf, clamp the cable, get a reading of 495 lbf, and adjust the force value to 500 lbf. Since we clamp and then adjust to the force value, the results are like using deadweight as we have manually compensated for the increased tension of the tensiometer by decreasing the distance between the two fixed points.

Method 2 Clamp tensiometer. This method is when the force is applied at the desired reading, the cable is clamped, and the value is read. In this scenario, the applied force might be 500 lbf, and when clamped, the value might jump to 528 lbf.

Replicating Real-World Use:

While the calibration process typically involves securing the tensiometer and applying a known tension first, the cable loading method (Method 2) better represents real-world usage.

In this method, the force is applied to the desired level, the cable is clamped, and the reading is taken. This captures not only the actual cable tension but also the slight internal tension introduced by the tensiometer during measurement, which is present in actual field usage.

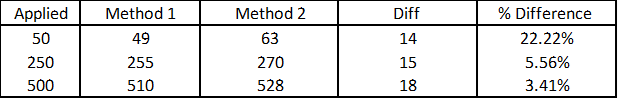

In an effort to ensure consistency, both calibration methods were tested using the same setup: a single cable, load cell, and Morehouse reference machine (Figure 7).

Comparing these two methods using five-foot long 3/16-inch cables yielded a significant difference. The most considerable difference was at the lower test points.

In principle, this makes sense as we shorten the distance between the two cables by grabbing it with the tensiometer. That is a fixed distance that is repeatable; thus, the difference is close to a constant one.

Clamping the tensiometer shortens the effective length of the cable. This modification in effective length influences the increase in tension and forces read, which directly relates to the overall "spring rate" of the system.

Note: Our tests used a digital tensiometer, which does not introduce as much internal tension as some analog tensiometers.

The Type of the Cable GAC versus SSAC

GAC is short for Galvanized Aircraft Cable, while SSAC is Stainless Steel Aircraft Cable.

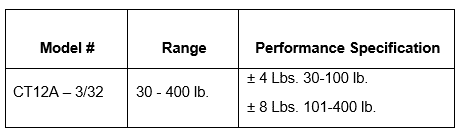

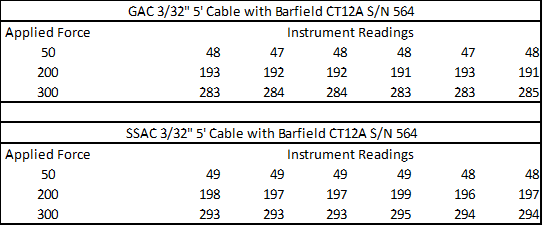

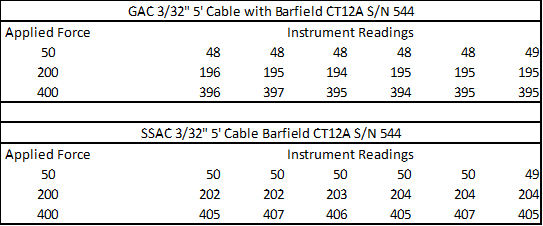

We used "Method 1" for the comparison tests with two 3/32-inch cables and two tensiometers with the following specifications below.

The Data

Overall, Barfield CT12A units performed very well. The standard deviation from test multiple points was typically one lb. or better. The variation between six repeated measurements varied from 1 to 3 lb. per point. The repeatability data varied from a minimum of 0.41 to a maximum of 1.03 lb.

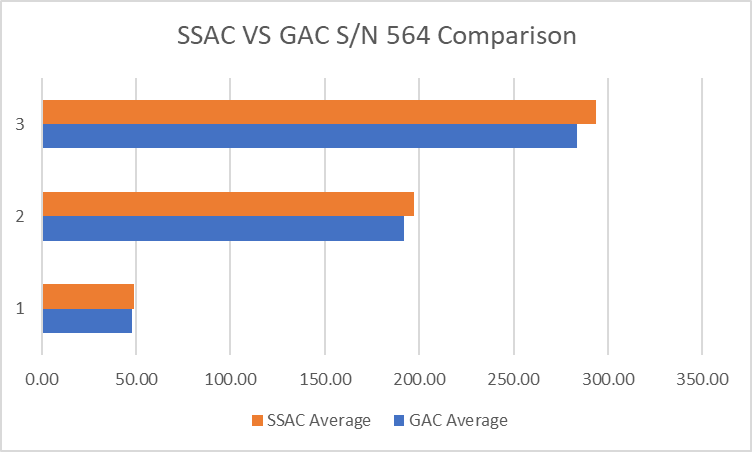

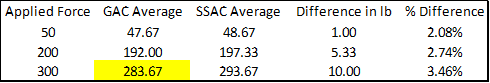

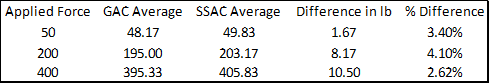

Comparing the different cable types SSAC versus GAC

We compared the GAC and SSAC on two different cable tensiometers. The highlighted cell in the above figure from the comparison using S/N 564 shows the measurement in which the unit does not meet the specifications of ± 8 lb. from 100-300 lb, which might result in a failed calibration and an adjustment when the tensiometer is within the specification.

Note: When considering measurement uncertainty, the expanded measurement uncertainty at a confidence interval of 95 % is around ± 0.5 lb., which would decrease the acceptance.

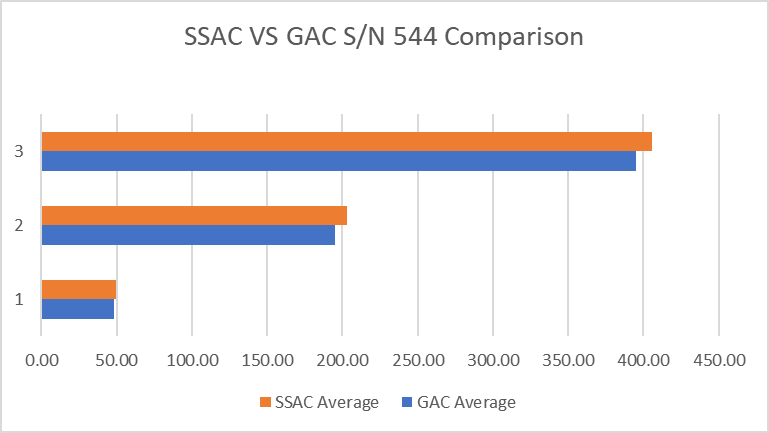

Figure 15: Comparison Data using S/N 544 Tensiometer Graphed.

The tension readings between 3/32" SSAC and 3/32" GAC cables vary. The end-user must assess if their specific tensiometer meets their testing requirements for both cable types, considering the observed variations and their associated risks.

The manual for the CT12A tensiometers confirms this by mentioning that SSAC needs a different calibration than GAC (found in Ch. 2 sec. 4).[1]

If the measurement is at the tolerance limit, there would be a 50 % risk, and the unit is either good or bad. If the specification were from 30 – 100 lb. to be within ± 4 lb. & from 101 -400 ± 8, then S/N 544 would fail using a GAC cable, while S/N 564 would pass.

How to Calibrate Cable Tensiometers Conclusion

Calibrating cable tensiometers involves using the right equipment, such as a calibrated load cell and appropriately sized cables, and following specific processes to ensure accurate tension measurements for various cable types.

However, a crucial question remains: which calibration method best reflects the actual end-use conditions for the equipment? Are calibration laboratories actively engaging with their clients to determine the method that best replicates how the equipment is used?

Failing to do so could result in profound implications. If one method is used on an airplane, maybe a pilot will complain about the rudders being too tight, which can impact the ability of a pilot to turn an airplane.

[1] Barfield CT12A Digital Cable Tensiometer

Revision E May 29, 2009

More Information about Morehouse

We believe in changing how people think about force and torque calibration in everything we do.

This includes setting expectations on load cell reliability and challenging the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition.

We turn around your equipment in 7-10 business days so you can return to work quickly, saving you money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff.

Our YouTube channel has videos on various force and torque calibration topics here.