Without the Right Adapters, a Force Calibration Technician is Nothing Short of Being Called a Miracle Worker

Figure 1 Bent Rod End

Think about that for a minute. Would you want a surgeon to operate on you with kitchen utensils such as a serrated knife? Then why do some people (management cough) expect or ask the force calibration technician to calibrate load cells, truck & aircraft scales, tension links, dynamometers, and other force measuring devices with whatever they have in their laboratory? Adapters that could range from unsafe to an improperly machined adapter that allows them to fixture the force measuring device in the frame to apply forces and record output at those forces.

You must ask why is this happening? Is it just that people are oblivious to the importance of adapters in mechanical measurements? The purpose of this particular blog is to examine safety concerns with using older adapters and discuss some of the error sources associated with using the wrong adapters. We will leave the rest up to the reader on whether it makes sense to seek out the appropriate adapters and have skilled calibration technicians or simply hope the technician can maintain the “miracle worker” title.

Though some calibration technicians may still wear the miracle worker hat when the manufacturer writes specifications that were achieved once and never repeated, but I regress as this is an educational post and we will not be discussing unrealistic specifications. Instead, we will be discussing using the adapters that will give a calibration technician the highest probability of meeting those specifications.

Figure 2 Grade 8 Bolt that Failed at 120,000 lbf and close to 350,000 load cycles

Let’s start with those old adapters that have been in use for decades. The service life for force calibration adapters depends on several factors including material, design, manufacturing, number of load cycles, and magnitude of each load. There may come a time when the material begins to lose strength as the result of fatigue and eventually breaks.

Today, there are better material and manufacturing control processes in place that provides more reliable strength values for design engineers than decades ago. There are also computer programs that greatly help in modeling and conducting all kinds of stress analysis. We often get asked, "What should we do with older adapters?" Our guidance is to visually inspect all adapters for any signs of wear or fatigue and replace if they show any signs of potential failure. We recommend replacing adapters that have been in use for more than 20 years or 100,000 load cycles (10,000 calibrations).

Adapters today are designed for a life cycle of at least 500,000 load cycles (50,000 calibrations) and failure at close to 1,000,000 load cycles. Now that we have explained some safety recommendations, let’s start to discuss some examples where the proper adapters are going to yield better results.

Common Adapters to Reduce Force Measurement Error

Keeping the line of force pure (free from eccentric forces) is key to the calibration of load cells. ASTM E74-18 in note 5 states “Force-measuring instruments have sensitivity in varying degrees depending on design to mounting conditions and parasitic forces and moments due to misalignment.

A measure of this sensitivity may be made by imposing conditions to simulate these factors such as using fixtures with contact surfaces that are slightly convex or concave, or of varying stiffness or hardness, or with angular or eccentric misalignment, and so forth. Such factors can sometimes be significant contributors to measurement uncertainty and should be reflected in comprehensive measurement uncertainty analyses.” ISO 376 has an entire Annex devoted to adapters.

Morehouse Tension Member Assemblies

Figure 3 Morehouse Tension Members

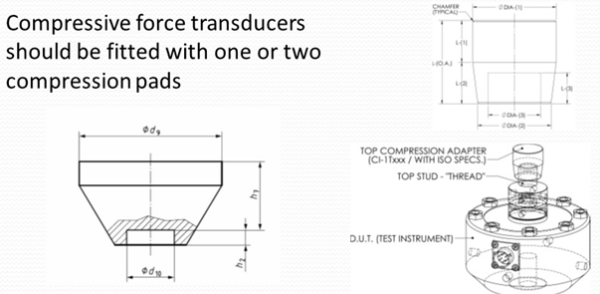

A good start to what makes a good tension or compression adapter is the ISO 376 standard. Annex A.4.1 of the ISO 376 standard says “Loading fittings should be designed in such a way that the line of force application is not distorted. As a rule, tensile force transducers should be fitted with two ball nuts, two ball cups, and if necessary, with two intermediate rings, while compressive force transducers should be fitted with one or two compression pads”.

Figure 3 above shows Morehouse tension adapters that have two ball nuts and two ball cups built into them to align the load cell with the loading line and eliminate misalignment errors in tension calibration. Website link to Quick Change Tension Members

Morehouse ISO 376 Compliant Compression Adapters

Figure 4 Morehouse ISO 376 Compliant Compression Adapters

Figure 5 Morehouse 200 lbf through 600,000 lbf Concrete set with top and bottom adapters

ISO 376 gives further guidance on baseplates and other adapters. In practice, A flat bottom plate may be needed to improve performance. It is often not recommended the practice to load against the machine surface as it could be uneven, or the base of the load cell could deform the machine surface. For compression adapters, ISO 376 generally requires adapters that bring the contact pressure between load measuring device and machine under calibration to lower than 100 N/mm2.

In addition, the hardness of the top adapter used during calibration may change the way the force is distributed through the load cell resulting in errors of as high as 0.5 % of the applied force. Material having different hardness experiences different amounts of lateral deflection under the same amount of load. The hardness difference causes different amounts of stress between the block and load cell. The block's Flatness and smoothness are important because they will change the contact position on the load cell. The assumption is the load cell has a radius maybe R17 and is designed to be loaded exactly at the center of the spherical section, but an unbalanced or nonflat block can shift the contact point off-center.

In general, a small amount of shift in force application point will change the stress distribution. The key is to use the same adapters in use as used in calibration. The adapters should be manufactured not to produce off-axis loads. Load cells often have a steep radius that concentrates the force over a smaller area and may cause the material to deform permanently. The deformation is why we recommend having a Morehouse compression top block mated to any load cell as shown in Figure 5. For flat adapters, the two parallel surfaces must be ground to maximum parallelism. In case of noticing any damage or dents in compression pads, they should be reground and cleaned prior to calibration. Website link to Concrete 600K set with adapters

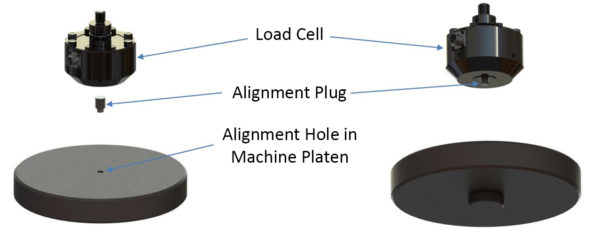

Morehouse Alignment Plugs for Better Centering

Figure 6 Morehouse Alignment Plugs

Next is proper bottom alignment adapters to help to align a load cell and other calibration fixtures to the load line of the calibrating machine. No matter how good an operator may be, they are no match for something machined with precision. By having bottom adapters with concentric rings for alignment or alignment plugs to perfectly center the force-measuring instrument, the end-user is going to be able to reduce misalignment error. Morehouse has observed misalignment errors of up to 0.75 % on S-Beam load cells with less than 1/8” misalignment. Alignment plugs and base plates with alignment holes in Figure 6 drastically reduce this error.

Morehouse Common Compression Adapters for Load Cells

Figure 7 Morehouse Top Alignment Adapters

For the top of the load cells, we recommend loading with either a spherical or ball adapter pictured in Figure 7. In compression, using a ball adapter (pictured top right) if the machine has a ball seat adapter often yields the best results. If a ball adapter does not exist, a spherical alignment adapter (pictured top left) will help align the force. The recommendation is to use a spherical alignment adapter for any load cell that is not a shear web load cell with a female thread that needs to be calibrated in compression. For a shear web load cell, we recommend installing the integral threaded adapter.

The shear web load cell is very susceptible to varying thread engagement, and the integral adapter eliminates this error. For those that still need to use a shear web-type cell and have height restrictions, a spherical adapter is recommended, but will not produce as good of results as an integral threaded adapter. Website link to Adapters

Morehouse Common Compression Adapters for Button and Washer Type Cells

Figure 8 Morehouse Button and Washer Load Cell Adapters

The number one complaint with button and washer load cells is how to get them to repeat between rotations. These load cells are notoriously sensitive in rotation, and any misalignment will produce large errors. Above are pictures of Morehouse button and washer load cell adapters which improve alignment and yield better calibration results usually the results are better by a factor of 5 or when using the above adapters as compared with a technician trying to center as shown in figure 9 below. These adapter sets can also accommodate alignment plugs (Figure 6) to align the whole calibration setup with the calibration machine; a deadweight system, hydraulic Universal Calibrating Machines (UCM), or Morehouse Portable Calibrating Machine (PCM).

Figure 9 Typical button load cell calibration versus one with Morehouse Adapters

Website link to Button Cell Information & Washer Load Cell Information

Tension links are up next, and the output of a tension link is influenced by the size of the pin used during calibration. The recommended practice is always to calibrate the tension link with whatever the end-user is using it. Pins sold with the tension links are typically cast or forged and during use develop uneven wear patterns so marking the pins “top” and “bottom” is highly recommended as well as noting the orientation. In several cases, the end-user may send the link in for calibration without any adapters at all.

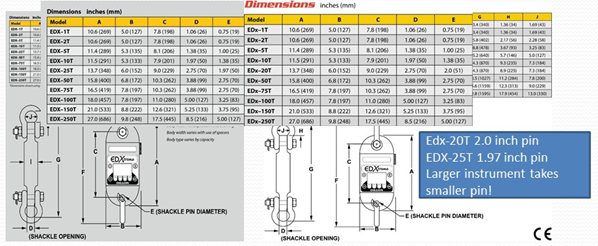

Morehouse Tension Clevis Adapters for Tension Links, Crane Scales, and Dynamometers

Figure 10 Tension Link Difference in output with pin size

If the calibration lab then decides to use a pin that is different from the manufacturer’s recommendations, there will be a larger than expected bias. In Figure 10, a Tension link was loaded into our deadweight machine with an accuracy of better than 0.002 % of applied force and loaded to 50,000 lbf with two different-size load pins. When loaded with a smaller pin of 1.85 inches the device read 49,140 compared to being loaded with a 2-inch pin and reading 50,000 lbf. When the end-user does not send in an adapter, the calibration laboratory is left with having to load the device with some pin.

Figure 11 Manufacturer's specification sheet for tension links

Finding the right pin size can be tricky as shown in Figure 11 as the manufacturer’s recommendations may be counter-intuitive. In Figure 11 example, a 20-ton tension link requires a 2.0-inch pin, and a 25 ton requires a 1.97 (50mm) pin. One may say 0.03 inches will not make a difference and we would say go ahead and test it. On a device with an accuracy specification of 0.1 % of full scale, we have observed a change of 0.03 inches to use up 70 % of that specification.

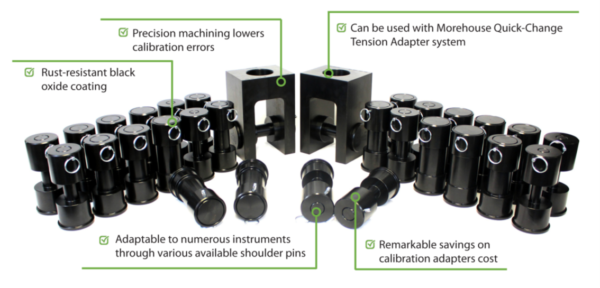

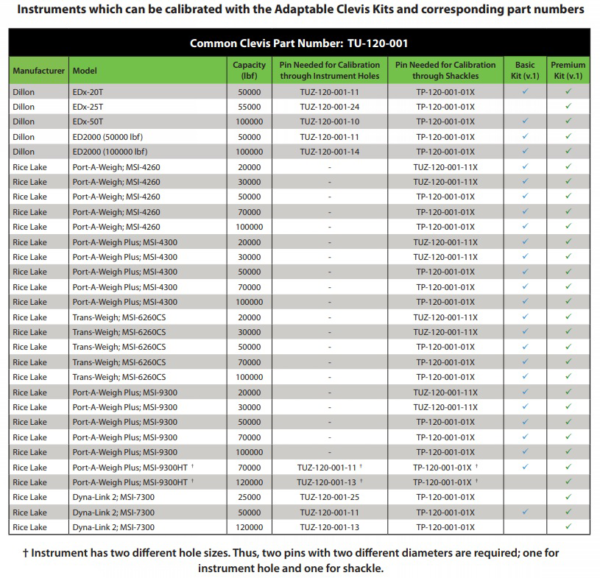

Figure 12 Morehouse Clevis Kits

Knowing these issues, Morehouse has designed clevis assemblies for use with our Quick-Change Tension Adapters. These assemblies cross-reference the manufacturer’s recommended pin size and allow the calibration laboratory to calibrate hundreds of tension links, crane scales, dynamometers, and rod-end load cells all with using the same clevis. Not only does this simplify the logistics of having the proper adapter, but it improves cycle time and standardizes the calibration process. Link to Morehouse Clevis kits.

Figure 13 1 of 3 pages of model numbers the Morehouse Adaptable Clevis Kits can be used to calibrate

Morehouse Adapters for Truck and Aircraft Scales

When someone calibrates a scale using weights or a hydraulic cylinder are they simulating how the scale is used? Most truck and aircraft scales when in use have the truck or aircraft tire sitting directly on them. So how could it make sense to calibrate the scales without using an adapter that replicates actual use? Any adapter used during calibration should be composed of the same type of rubber and should have the same footprint as the tire to ensure accurate results. Morehouse has a line of aircraft and truck calibration presses. We can make adapters for any scale that simulate the tire. For more information, please visit our website. Link to Aircraft and Truck Scale Calibrators

Morehouse Adapters for Hand-Held Force Gauges

Are you or your calibration technicians tired of lifting weights to calibrate hand-held force gauges? Calibrating some of the hand-held force gauges is like playing Jenga when a technician must stack weights in compression and what happens when those weights fall and shatter a toe? Fortunately, we have developed a portable calibrating machine with kits for hand-held force gauges.

Figure 14 Morehouse Portable Calibrating Machine with Hand-Held Force Gauge Adapters

The 2,000 lbf capacity Morehouse PCM can handle any force instruments. The machine can use the washer and load button adapters for compression calibrations of those types of load cells as well as common tension setups and hand-held force gauges. The hand-held force gauge kit simplifies the setup and allows the technician to calibrate these types of gauges in the same setup while keeping the line of force pure by using different offset plates included in the kits. These kits simplify setup, improve alignment, and drastically improve safety. The kits are also available for Morehouse Deadweight and Universal Calibrating Machines. Link to Hand-Held Force Gauge Kit

Force Calibration Technician Morehouse Miscellaneous Adapter Information - Conclusion

Morehouse can make adapters for almost any force application from small (1 lbf) to large (2.5 million lbf). Morehouse has also designed and manufactured adapters for calibrating various multi-axis load/torque cells which enables a laboratory to calibrate such cells in single-axis calibrating machines. If you have an instrument that is not listed here, please contact sales@mhforce.com.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment. We challenge the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors, and focus on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.

#Force Calibration Technician