The Morehouse team can calibrate your hardness tester.

The Knoop resulting indentation is not symmetrical as Vickers indentions and is subject to more variations, especially below 200gf.

Knoop hardness is not typically being used to define bulk hardness, although at 500 gf standards like ASTM provide conversions of Knoop results to other hardness test scales.

Knoop Hardness Testing:

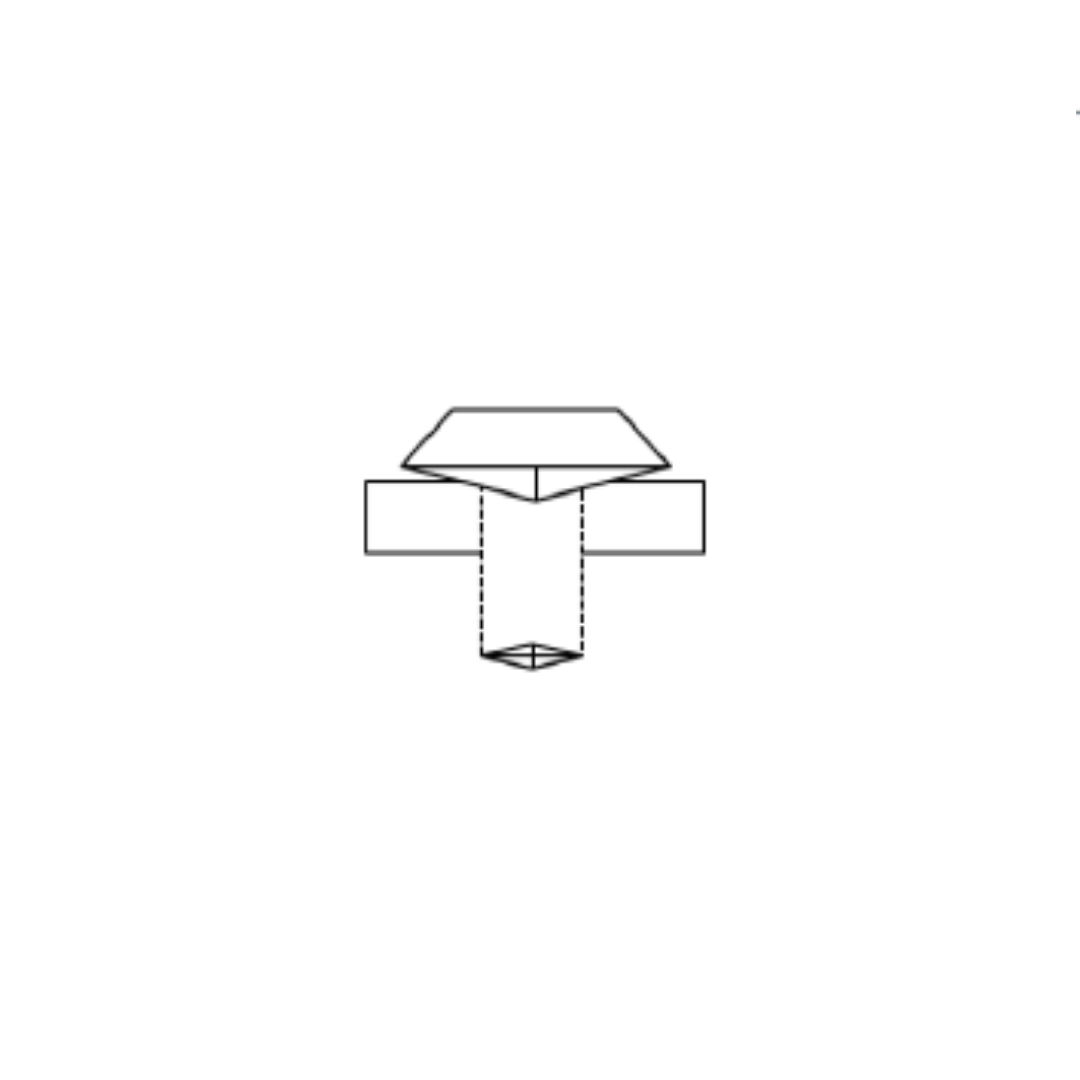

Knoop Hardness Testing:The Knoop resulting indentation is not symmetrical as Vickers indentions and is subject to more variations, especially below 200gf. Knoop hardness is not typically being used to define bulk hardness, although at 500 gf standards like ASTM provide conversions of Knoop results to other hardness test scales. Knoop tests are not typically performed at test forces above 1000 gf, although particular circumstances and or materials may need higher forces like 2 and 5 kgf. Expect larger variations in results at these loads. The Knoop diamond indenter is designed with a significant difference between the long and short Knoop diagonals, which is often better suited for determining variations of hardness over very small distances compared to the Vickers indenter.

The success of the specimen preparation procedure in removing preparation-induced damage can and will influence test results; this problem becomes more critical as the test force decreases.

One of the common threads you should notice here is that defined forces are applied to the indentor, irrespective of test type, and this is where Morehouse provides a solution in the form of calibration of the loadcells that are used to measure the amount of force applied during each of these tests.

Morehouse can help with supplying load cells and calibration done using primary deadweight standards/

For more information on Knoop Hardness Testing, the ASTM C1326-13 standard is recommended.

# Knoop Hardness Testing