Tension Link Calibration (3 Easy Steps to Yield Repeatable Results)

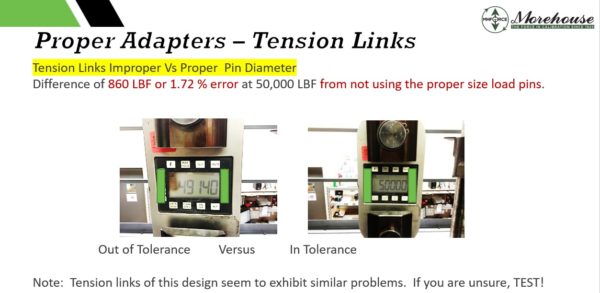

Tension Link Calibration requires advanced knowledge of the calibration process to pass an instrument. There will be additional errors if there is any variation in the adapters used for calibration. Here at Morehouse, we have done testing using different pin sizes and adapters. Forged pins, for example, can differ by small amounts in diameter from pin to pin.

Depending on the Scale manufacturer, we have seen differences up to 1.7% between different sets of pins. If your instrument has an accuracy of 0.1%, your error could be 17 times greater by substituting pins.

This blog lists the top 3 things that need to be followed regarding tension link calibration and keeping them in tolerance from calibration to actual use. The top 3 things to follow are:

- Use the appropriate pin size;

- If the pins have irregular sizing, label the top and bottom pins and note the position;

- Use the appropriate equipment and adapters.

#1 Use the appropriate pin size

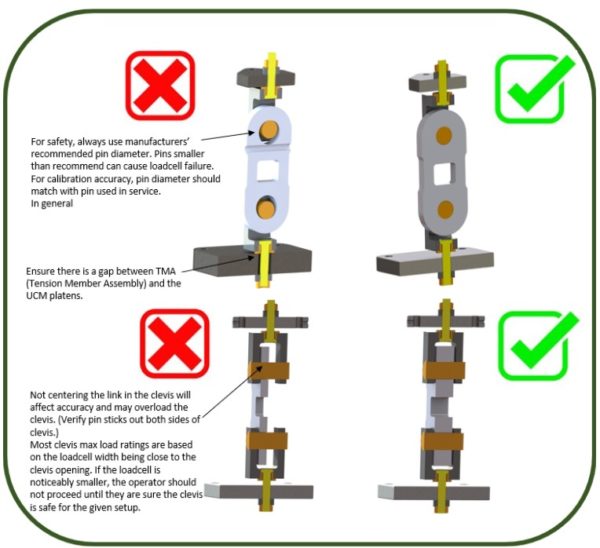

In general, pin diameter and the clevis hole size must be a close fit and for safety, always use the manufacturer's recommended pin diameter pins smaller than recommended can cause failure.

The above picture shows a test Morehouse performed using two different size pins, A 50 mm pin which yielded a result of 50,000 lbf when 50,000 lbf was applied, and a 1.75 " inch pin, which yielded a result of 49,140 lbf when 50,000 lbf was applied. The results were very significant as the manufactures accuracy of this Tension Link is 0.1 % of full scale.

It is an understatement to say that tension link calibration requires the same pin size during calibration used in the field. Not following step 1 will almost certainly lead to significant measurement errors.

#2 If the pins have irregular sizing, label the top and bottom pins and note the position.

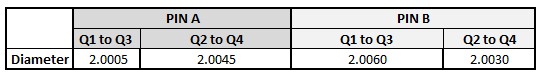

We use the correct pins with the unit, although our pins vary slightly in diameter. However, this does not produce the significant errors as in #1; it can be enough to fail the instrument during calibration.

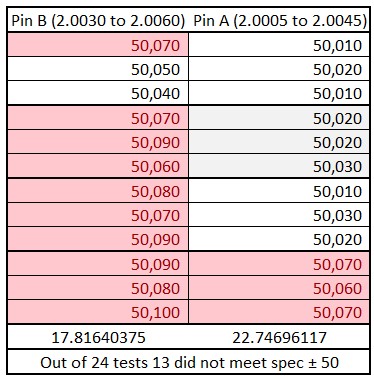

Shown above are pins labeled A and B, and each corner has been labeled. The pins were measured using these coordinates.

A maximum variation of 0.0055 isn't much, is it? This could easily happen with repeated loadings as most pins are cast and will wear over time. The main issue is when the wear starts to happen, maintaining calibration becomes more difficult.

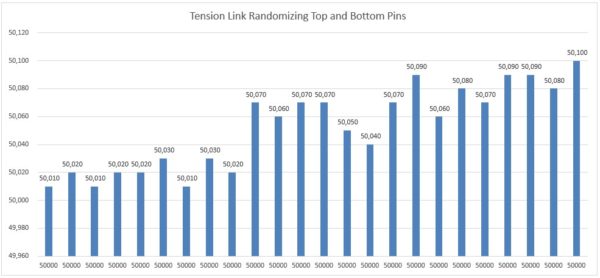

The above graph shows what happens when we do not label the pins and use A and B at random positions. Some measurements are within the specification, and others are not.

13 out of the 24 samples did not meet the specification. This further supports that labeling the top and bottom pins is the best practice and should be required for tension link calibration. If your pins are worn, we can help find replacements. We have several solutions if your customers are not sending their pins, or you can standardize your process with machined pins.

# 3 Use the appropriate equipment and adapters.

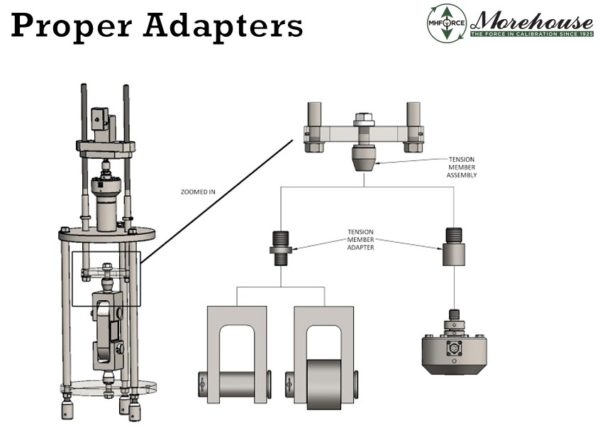

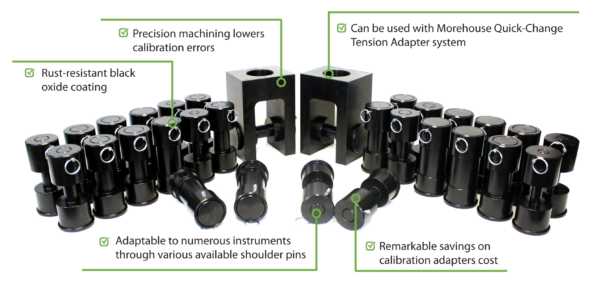

We discuss Tension Link Calibration Adapters, including an appropriately sized Clevis set to use the customer-supplied pin, load with the shackle, and adapters to ensure the forces are centered. Adapters pictured below are designed with sphericals to limit misalignment.

Morehouse Clevis assembly for tension adapters are used to calibrate dynamometers, load links, tension rods, crane scales, or other weighing devices. The assemblies can be used with Morehouse Quick change Tension Members to minimize errors by improving tension alignment. The Clevis assemblies are Patented (No. 11,078,052).

If following these guidelines for tension link calibration is too much headache, please know we offer several other products, such as Ron/Eilon Crane Scales.

Morehouse is an authorized distributor of Eilon Engineering products such as Ron Crane Scales. These crane scales are repeatable, and because their design is different, they do not have the same measurement errors as tension links. The Ron units have five main families to solve your lifting needs. If you are in the procurement phase and want to standardize your weighing equipment to avoid common errors associated with tension link pin size, please click here or contact Morehouse @ sales@mhforce.com

Tension Link Calibration - Additional Safety Notes for Using Morehouse Clevis Setups & Adapters

Tension Link Calibration Safety Notes:

1) Ensure the clevis pin is fully inserted. If the design includes safety pins, ensure they are installed before loading.

2) Some tension link load cells are designed with a none cylindrical hole or very large chamfers. This effectively reduces the contact area on the pin and will decrease the maximum load capacity of the pin.

3) Never use fixtures that don’t have traceability back to their load ratings. Always remember load ratings must be reduced if the setup does not match the original design intent.

Tension Link Calibration (3 Easy Steps to Yield Repeatable Results) - Conclusion

I take great pride in our knowledgeable team at Morehouse, who continue to work with everyone, clarify complex topics, and provide tools such as free guidance documents, excel sheets, and products to help you make better force measurements. We want to make sure everyone knows the basics of tension link calibration.

At Morehouse, we educate our customers and provide solutions to you. Most of these solutions are available for free to help you make better measurements and can be found here.

We have been in business for over a century and focus on being the most recognized name in the force sensor calibration business. That vision comes from educating our customers on what matters most and having the proper discussions about tension link calibration.

Everything we do, we believe in changing how people think about force and torque calibration. We challenge the "just calibrate it" mentality by educating our customers on what matters, what causes significant errors, and how to focus on reducing them. In addition, Morehouse makes simple-to-use calibration products. We build excellent force equipment that is plumb, level, square, and rigid.

If you have more questions about tension link calibration, need adapters, load cells, calibration, or other questions don't hesitate to get in touch with us @ 717-843-0081 to talk to a live person or email info@mhforce.com. Visit us on the web at mhforce.com.

#Tension Link Calibration

Want to learn more? Watch our video on Tension Link Calibration.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.