Shipping Measurement and Test Equipment (MT&E) For Shipment

Shipping Measurement and Test Equipment Packing Specialist

The word improper is defined as unsuitable for a certain use or occasion. Improper packing is often the leading cause of damage occurring during shipment. Investing in the proper shipping containers and proper training for those packing equipment should be one of your company's highest priorities.

Though some containers may be more expensive, they are much cheaper than dealing with damaged equipment. This blog is going to describe the good, the bad, and the ugly in relation to Shipping Measurement and Test Equipment (MT&E).

The Good

A Pelican case with custom-cut foam is great for shipping measurement and test equipment. The case is durable, and the foam protects the equipment from moving during shipment. It secures all instrumentation and shipping damage is rarely reported. We have only observed two damage reports in the last 5 years from this type of packaging. One report was from a piece of threaded rod piercing a case, and the other was from this type of case getting stuck on a conveyor belt.

Morehouse Load Cell and Two Boxes

Double Boxing

Certificates Enclosed

More examples of good shipping practices are double boxing. This involves placing the MT&E in a cardboard box. The box is usually surrounded by packing material and then placed in a larger box and surrounded by more packing material. This method requires additional storage space and may not be environmentally conscious.

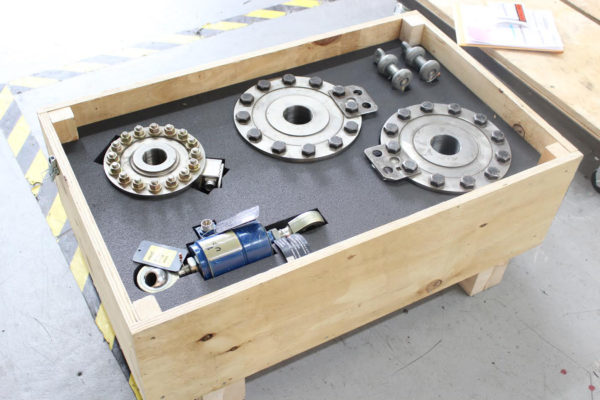

More good shipping practice with a wooden crate with custom-cut foam is good for freight and multiple uses.

The Bad

Blown foam can be great for packing a single item if the item does not exceed the weight limit for the foam. So long as the item is packed tightly, this method is acceptable. However, the item is often left loose, and any mishandling of the equipment can often result in connector or cable damage.

If there is more than one piece of equipment ie adapters and cables, then this method of shipment can result in damage. The picture on the right is a load cell with an integral connector. We have observed numerous shipments with the integral cable becoming pinched or severed with this shipping method.

Blown foam for packing

The Ugly

Equipment that is too heavy for a cardboard box. There is a false sense of security by attaching everything to a skid. Meters, cables, and other pieces are packed on top of the heavy equipment.

This type of shipment can make it to the destination safely if handled properly. "If handled properly" is the risk the shipper takes. If the equipment is mishandled, there is a very high probability of damage occurring especially when shipped further distances. More stops equal a higher risk of damage.

To pack this equipment properly involves an expensive custom case. We recommend investing in your equipment as anything packed in "The Bad" or "The Ugly" category is at risk for damage. The image below is an ugly outcome of the downside of using cardboard.

A wooden Skid that was Mishandled

Shipping Measurement and Test Equipment - Conclusion

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment.

We challenge the "just calibrate it" mentality by educating our customers on what matters, and what causes significant errors, and focusing on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.

# Shipping Measurement and Test Equipment