In the last Back-to-Basics blog, I covered Calibration versus Verification. As I continue to cover basic concepts for beginners, this blog will define measurement uncertainty and examine why it is important.

What is Measurement Uncertainty?

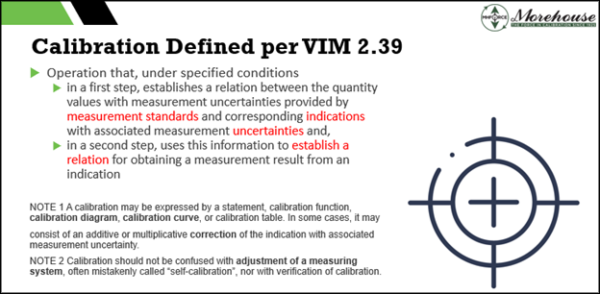

What measurement uncertainty is not is an error. It is imperative to understand the difference between these two terms as they are often confused. Error is the difference between the measured value and the device's actual value or artifact being measured. In many cases, we try to correct the known errors by applying corrections sometimes from the calibration certificate. These corrections can be a curve, a diagram, a table, and all items found in note 2 of the calibration definition from the VIM shown below.

Uncertainty, often referred to as 'doubt,' is the quantification of 'doubt' about the measurement result. The VIM in section 2.26 defines uncertainty as a non-negative parameter characterizing the dispersion of the quantity values being attributed to a measurand, based on the information used.

The VIM goes into further detail with several notes about the included components of measurement uncertainty, such as those arising from systematic effect, components associated with corrections, assigned quantity values of measurement standards, etc. Measurement Uncertainty compromises many components.

OIML G 19:2017 sums the definition of uncertainty as "the concept of measurement uncertainty can be described as a measure of how well the 'true' value of the measurand is believed to be known."

The best guide to Uncertainty is JCGM 100:2008 Evaluation of measurement data — Guide to the expression of uncertainty in measurement, free to download here.

In general, when you calculate measurement uncertainties following the ISO "Guide to the Expression of Uncertainty in Measurement" (GUM) and ILAC P-14 as required by ISO/IEC 17025 guidelines, you will need to consider the following:

- Repeatability (Type A)

- Resolution

- Reproducibility

- Reference Standard Uncertainty

- Reference Standard Stability

- Environmental Factors

Morehouse has written several published documents on the topic of measurement uncertainty. We have created a spreadsheet tool to help everyone correctly calculate uncertainty for force following accreditation requirements and in line with JCGM 100:2008. That tool can be found here.

Why is Measurement Uncertainty Important?

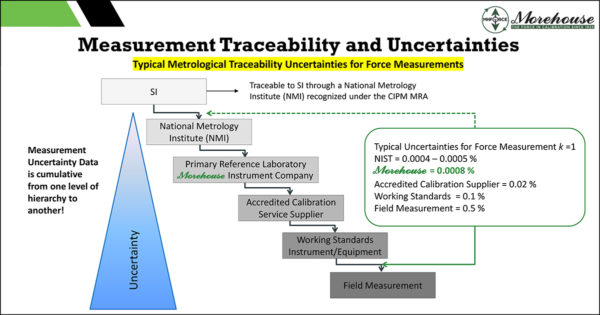

The uncertainty of the measurement is required to be reported on a certificate of calibrations if you are accredited to ISO/IEC 17025:2017, as well as several other standards, it is important if your customer may want you to make a statement of conformance on whether the device or artifact is in tolerance or not. It may need to be considered if you do a test and want to know if the device passes or fails. Measurement Uncertainty is required for establishing your measurement traceability, defined in the Vim as property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty.

In simplistic terms, measurement uncertainty is crucial because you want to know that the laboratory performing the calibration of your device or artifact can perform the calibration.

If you need a device to be known to be within less than 0.02 %, you must use a calibration provider that gives you the best chance of achieving that result. If the calibration provider has a stated measurement uncertainty of 0.04 %, mathematically, they are not the right calibration lab to calibrate or verify your device or artifact. Measurement uncertainty also keeps us honest. If a laboratory claims traceability to SI through NIST, the larger the uncertainty becomes, the further away from NIST. The above picture shows this concept as the further away from SI units, the larger the uncertainty.

Conclusion

Your Measurement Uncertainty is directly affected by the standards used to perform the calibration. Morehouse offers the lowest uncertainties for a commercial calibration laboratory. We work with customers to help lower their measurement risk. We have been successful in helping our customers make better measurements for over a century.

In our next Back-to-Basics blog, I will cover types of load cells.

Back-to-Basics series:

- Force Calibration and its Importance

- How a Transducer Measures Force

- Compression and Tension Force Calibration

- Calibration versus Verification

- Measurement Uncertainty

- Load Cell Terminology

- Types of Load Cells

- Load Cell Troubleshooting

- Load Cell Indicator Basics

- Force Measurement Glossary of Terms

I take great pride in our knowledgeable team at Morehouse, who will work with you to find the right solution. We have been in business for over a century and focus on being the most recognized name in the force business. That vision comes from educating our customers on what matters most: having the right discussions relating to force calibration basics so that everyone speaks the same language.

If you enjoyed this article, check out our LinkedIn and YouTube channels for more helpful posts and videos.

We believe in changing how people think about force and torque calibration in everything we do. We challenge the “just calibrate it” mentality by educating our customers on what matters and what causes significant errors and focusing on reducing them.

Morehouse makes simple-to-use calibration products. We build fantastic force equipment that is plumb, level, square, and rigid and provide unparalleled calibration service with less than two-week lead times.

Contact us at 717-843-0081 to speak to a live person or email info@mhforce.com for more information.