Load Cell Error- Load Cell Adapter Thread Depth Comparison

Budget Versus Shear Web

Load Cell Adapter Thread Depth Comparison - Introduction

We have written previous articles about using shear web load cells with a threaded adapter installed, meaning they are locked into place.

One article described the increased performance by locking a calibration adapter into the load cell, not to vary the load cell adapter thread depth.

In that article, we loaded the load cell against the shoulder and compared the results from a pre-loaded "locked-in" adapter versus loading against the shoulder.

The article "How To Make Load Cells Perform Better - 3 Benefits Of Installing A Threaded Adapter On Load Cells" can be found here.

We concluded that having the adapter locked into place improved both repeatability and reproducibility.

We showed a load cell, when calibrated per the ASTM E74 standard, improved by a factor of 42 %.

Then, we showed that varying the load cell adapter thread depth (difference in engagement of the threaded adapter) made the results vary.

On the load cell above, comparing the difference in output from engaging approximately 0.8" and locking and adapter in place resulted in a difference of around 0.17 %.

A video we filmed years ago showed a difference of around 0.2 % by varying the thread depth.

That video can be found here.

For this go around, we decided to do another test and compare a shear web load cell against our new budget load cells.

Load Cell Adapter Thread Depth Comparison - Differences in Design Characteristics

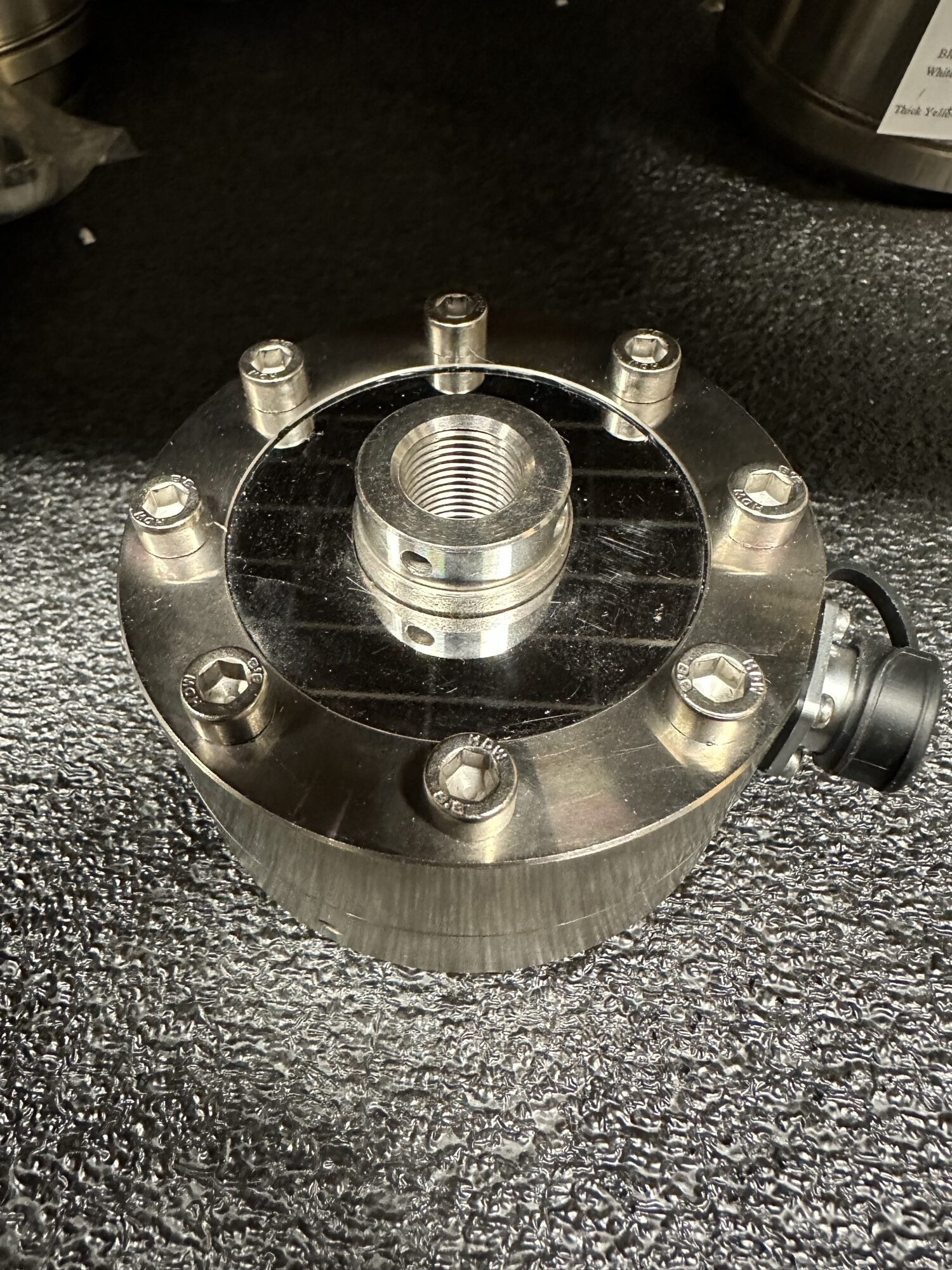

The budget load cells have a different design in which there is more material around the top threaded adapter, and the adapters are not pre-loaded to 140 % of capacity and then torqued in with a spanner wrench.

The hub on these load cells is higher and has more mass, and there is likely less susceptibility to bending strain.

In theory, the higher the hub, the better for reducing some errors.

They are a more straightforward design with excellent performance at a fraction of the cost.

You can see the difference related to the material in the center hub compared to a Morehouse Calibration Shear Web.

These load cells are carefully adjusted and polished internally on the web to maximize performance.

However, that performance is offset significantly If a threaded adapter is not installed.

The threads are locked when a calibration adapter with a jam nut is installed, with a high force (140 % capacity) to lock it in.

This locks the threads in, thus keeping the ring in shear, preventing the threads from moving under load and reducing unwanted bending strains.

Load Cell Adapter Thread Depth Comparison - Testing Thread Engagement on Each Type of Load Cell

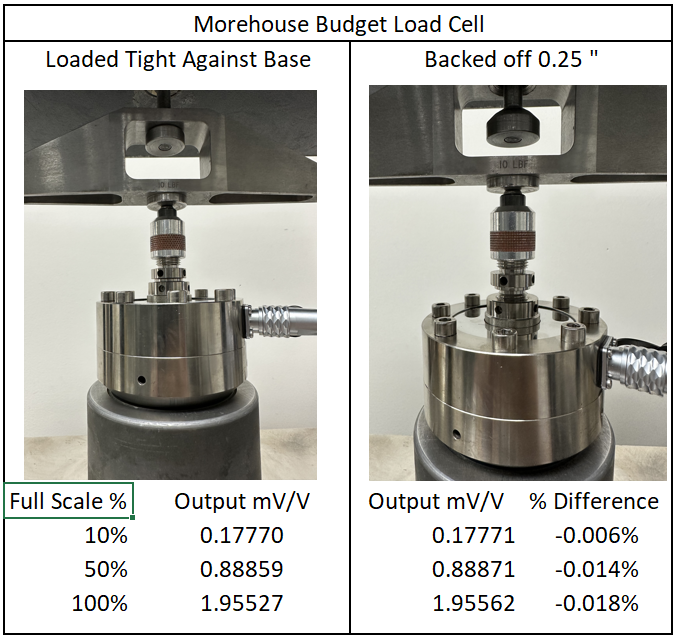

Since the load cells have slightly different designs, we decided to do a more thorough comparison by setting the load cell adapter thread depth to be high by about 0.25 inches and comparing that against threading the adapter in had tight on both load cells.

In the figure above, we are recording mV/V values, comparing the difference with the adapter threaded tight, using the same load cell adapter, and backing it off 0.25 inches.

The difference between these two readings approached a difference of about 0.02 %.

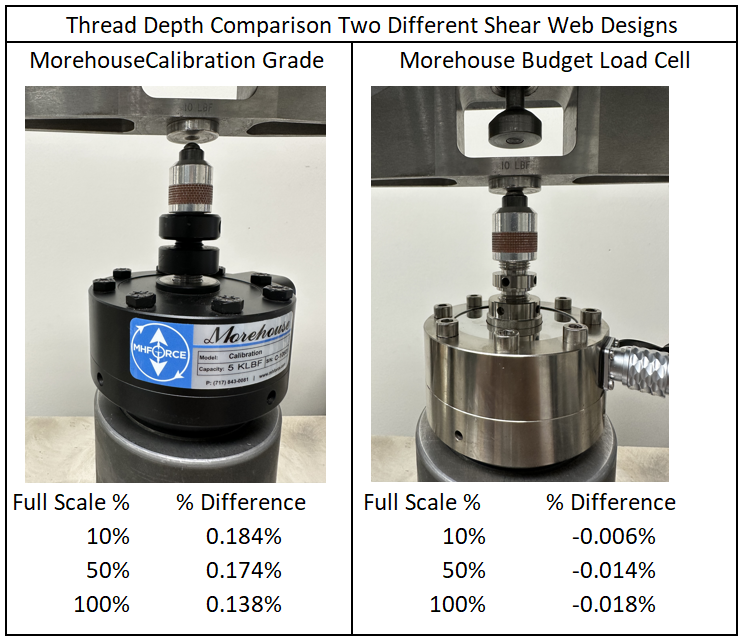

When we did the same test using our calibration grade cell, we saw a more dramatic difference between loading the adapter tight and using the same load cell adapter and backing it off 0.25 inches.

Varying the load cell adapter thread depth on both load cells produced a noticeable difference in output.

The Morehouse Calibration grade load cell shows more sensitivity to varying thread depth compared to locking an adapter into place by about a factor of 10.

This makes sense as a calibration adapter is not locked into place, and the load cell is much more susceptible to bending strains.

The difference in the design of the budget load cell seems superior when it comes to the overall error from different thread depths, though this one characteristic does not make them a superior load cell.

Load Cell Adapter Thread Depth Comparison - Conclusion

- The different design characteristics of the Morehouse budget load cell make the error from varying thread engagement less than that of a more traditional shear web design.

- The optimum performance of the Morehouse Ultra Precision and Precision Shear web load cells is maximized when the threaded adapter is locked into place, reducing bending strains that can cause damage to the load cell.

- From years of performance testing, the Morehouse shear web load cells demonstrate excellent repeatability, reproducibility, and stability when the calibration adapter and jam nut are locked in and not tampered with.

Note: Looking at over 500 samples of Morehouse Shear Web load cells, the overall stability from year to year at about a 95 % confidence interval is around 0.05 % from 10 % of the loading range, assuming the load cell is paired with a HADI, or 4215 plus, or High Stability indicator.

- Our standard line of Morehouse shear web cells is highly recommended if you want guaranteed performance and can live with the increased height.

- The different design of the budget load cell made of non-corrosive alloy steel might be a better choice for anyone who chooses not to lock an integral threaded adapter into place.

- The recommendation is to have the calibration laboratory replicate how you use it, so purchasing adapters from Morehouse or sending in your adapters with instructions should help minimize errors.

- In all cases, locking adapters into place will minimize bending strains, making the load cell perform better.

We have a YouTube video showing the differences between locking an adapter into place and loading through the threads.

We believe in changing how people think about force and torque calibration in everything we do.

This includes setting expectations on load cell adapter thread depth and challenging the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition.

We turn around your equipment in 7-10 business days so you can return to work quickly, saving you money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

And if you ever want to chat or have questions about a blog, email us.

We love talking about this stuff.

Please visit our YouTube channel for more information on load cell errors that can impact reliability, or read our other posts.

# Load Cell Reliability

# load cell adapter thread depth