How to Calibrate Cable Tensiometers

Does the Type of Cable GAC versus SSAC Make a Difference?

What is a Cable Tensiometer?

Cable tensiometers are devices used to measure the tension or force in cables, wires, and ropes.

They are commonly employed in engineering, construction, and industrial applications to ensure the proper tension of cables to prevent overloading or under-tensioning, which can impact safety and performance.

These devices typically feature a load sensor or gauge that provides real-time tension readings.

How to Calibrate Cable Tensiometers.

Calibrating a cable tensiometer involves knowing the right requirements, having the right equipment, and the right processes.

How to Calibrate Cable Tensiometers: The Right Requirements

What is needed to accomplish this task? In the case of cable tensiometer calibration, does it make a difference what type of cable is being used? More on that later.

How to Calibrate Cable Tensiometers: The Right Equipment

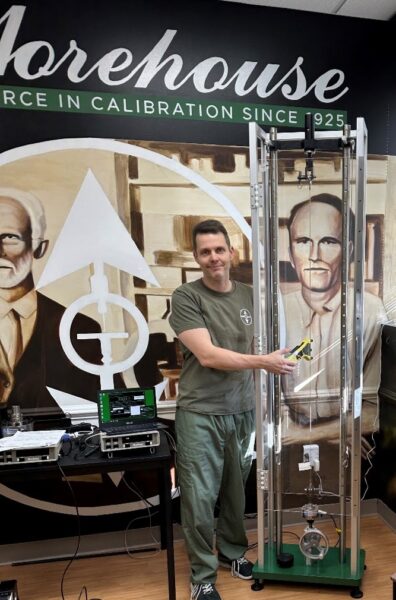

In this image, Henry Zumbrun is using a Morehouse Cable Tensiometer Machine (PCM-2MD-T1) and a 500 lbf Morehouse load cell reference standard that was calibrated using the ASTM E74 standard using deadweight primary standards known to be better than 0.002 % of applied force.

Note: The Expanded Measurement Uncertainty for the Morehouse Cable Tensiometer typically falls between 0.02 % and 0.04 % of applied forces.

The right equipment may also consist of cables of 3 feet or greater. For all our tests presented, we use cables five feet in length. Some systems use cables that are 18 – 24 inches, and these shorter cables can lead to different results.

It is essential to read the manufacturer’s recommendations and set up the tests to replicate what is needed. For instance, we use 5-foot cables because that is what the USAF procedure uses.

How to Calibrate Cable Tensiometers: The Right Processes

For cable tensiometers, this might be as follows:

Apply the reference force: Attach the reference standard to the tested cable or wire and apply the known tension or force.

Then, clamp the device to the cable, adjust the force to the desired reading, unclamp it, and clamp it again. This method would be equivalent to one fixed point, such as the hanging weight method.

There is another method of clamping after a known force is applied. Depending on the cable size, these methods produce a significant difference.

Compare readings: Read the tension measurement on the cable tensiometer while the reference load is applied. Compare this reading to the known reference standard value.

Repeat as needed: Take as many measurements as deemed necessary; in our testing, we took six measurements at each test point to have confidence in the repeatability numbers for comparison between cables.

Record calibration data: Document the calibration process, including the reference standard used, the measured values, and any adjustments made.

Note: It's essential to follow the manufacturer's guidelines and recommendations for calibration specific to your cable tensiometer model, as the process can vary between devices.

Testing SSAC and GAC 3/32” Cables

GAC cable is short for Galvanized Aircraft Cable, while SSAC is Stainless Steel Aircraft Cable.

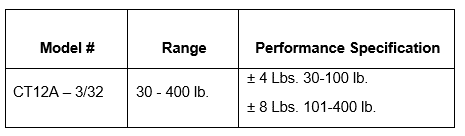

For the comparison tests, we used two 3/32” cables and two tensiometers with the following specifications below.

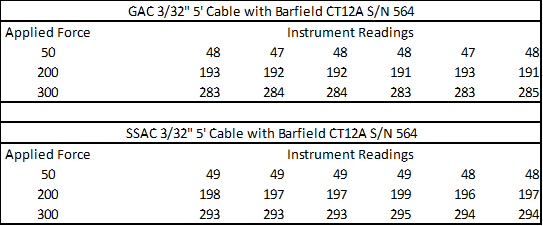

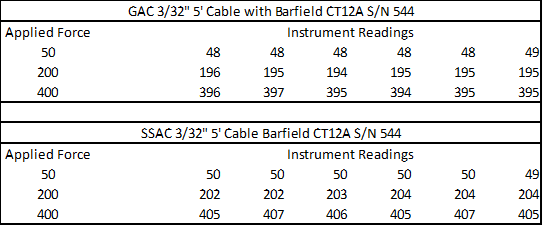

The Data

Overall, Barfield CT12A units performed very well. The standard deviation from test multiple points was typically 1 lb or better.

The variation between six repeated measurements varied from 1 to 3 lb per point.

The repeatability data varied from a minimum of 0.41 to a maximum of 1.03 lb.

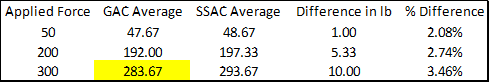

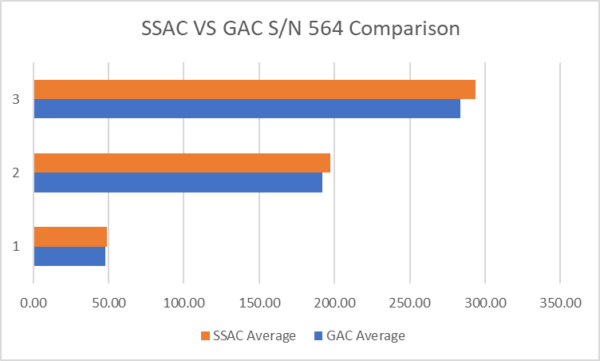

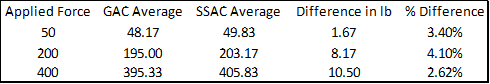

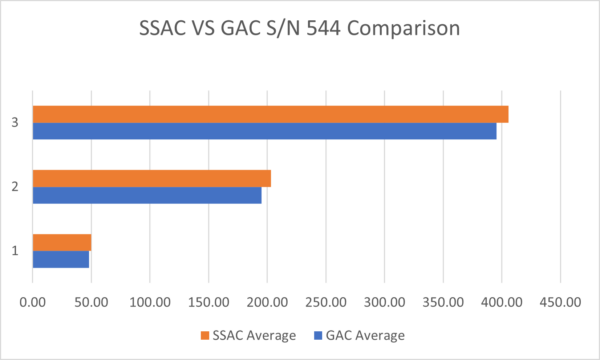

Comparing the different cable types SSAC versus GAC

Looking at the difference for a 3/32” SSAC versus a 3/32” GAC, there is a difference.

It would be up to the end-user to determine if the unit meets the requirements for testing tension on both SSAC and GAC cables and evaluate their level of risk. If the measurement is at the tolerance limit, there would be a 50 % risk, and the unit is either good or bad.

If the specification were from 30 – 100 to be within ± 4 lb & from 101 -400 ± 8, then S/N 544 would fail using a GAC cable, while S/N 564 would pass.

How to Calibrate Cable Tensiometers Conclusion

Calibrating cable tensiometers involves using the right equipment, such as a calibrated load cell and appropriately sized cables, and following specific processes to ensure accurate tension measurements for various cable types.

The difference in cable materials may impact the 3/32” and this model cable tensiometer results.

Morehouse offers cable kits, PCM-2MD-T1 Tensiometer Calibrator, and load cells.

For more insights into how to calibrate cable tensiometer, force and torque calibration, metrology, and load cell reliability, explore our comprehensive blog.

About Morehouse Instrument Company

Companies worldwide rely on Morehouse for accuracy and speed. The company turns around equipment in 7-10 business days so customers can return to work quickly and save money.

The York, PA-based company provides force and torque measurement products and services worldwide.

Morehouse Instrument Company, a trusted and accredited provider of force and torque measurement services for over 100 years, offers measurement uncertainties 10-50 times lower than the competition.

Morehouse helps commercial labs, government labs, and other organizations lower their measurement risk by lowering equipment uncertainties for torque and force measurement. Contact Morehouse at info@mhforce.com .

More Information about Morehouse

We believe in changing how people think about force and torque calibration in everything we do.

This includes setting expectations on load cell reliability and challenging the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition.

We turn around your equipment in 7-10 business days so you can return to work quickly, saving you money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff.

Our YouTube channel has videos on various force and torque calibration topics here.

# how to calibrate cable tensiometer