ASTM E74 Change From Previous to Meet a Two-year Calibration Interval

ASTM E74 Change From Previous to meet a two-year calibration interval is found in the ASTM E74 standard in section 11.2.1.

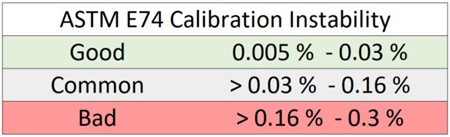

The standard specifically states, “Force-measuring instruments shall demonstrate changes in the calibration values over the range of use during the recalibration interval of less than 0.032 % of reading for force-measuring instruments and systems used over the Class AA verified range of forces and less than 0.16 % of reading for those instruments and systems used over the Class A verified range of forces. See Note 13.” 1

Of course, not all force-measuring instruments meet these criteria.

Being in the business of calibrating force and torque instruments means you will run across scenarios where the equipment sent in for calibration performs differently than the last calibration.

This blog will attempt to answer common causes of why a load cell might not meet these criteria.

- Cable Length - Is a cable different from what was sent for calibration being used? If so, the differences caused by varying the resistance could be significant if the system you are using is a four-wire system and the cables have been changed out. 4215s, HADIs, and C705P are true six-wire systems where this is likely not the cause. More information on four versus six-wire cables can be found here.

- Using different adapters than what was used last for calibration – This topic is pretty straightforward. If what is sent for calibration does not have mating adapters, then the calibration lab will likely use their adapters.In general, this could be a different threaded adapter, a different hardness of the top block, or someone removing an adapter and not putting it back at the same length. Our recommended compression and tension adapters paper covers these issues and many more. Using different adapters could easily be why the ASTM E74 Change From Previous is higher than expected.

- It was loaded differently – If you have an S-beam load cell, there are four ways to load it, and all produce different results. Here’s a blog on some additional thread engagement errors. If the load cell has threads, this could be the reason ASTM E74 Change From Previous is higher than expected.

- The load cell is overloaded or damaged - Many customers become shocked to learn it has shifted because it was improperly used. That could be because a technician overloaded the load cell; it could have been dropped. Small load cells can be overloaded by shutting a case on them.An overload will shift the output and can be why the ASTM E74 Change From the Previous is higher than expected. Luckily, there is a device to test your load cells before they are sent for calibration. This device is a load cell tester.

- The load cell is not that good - It happens occasionally when the load cell purchased has a high drift characteristic, likely due to improper gauging or material selection. We have seen a history of load cells where the instrument looks completely different if we take it out of the machine and put it back into the same machine. Some great load cells show differences of 0.001 % or better, and some horrible ones can show greater than 1 % difference.

- The Meter is not good - Several inexpensive meters out there do not have good drift or stability characteristics. If you buy a cheap indicator or some battery-powered device, there is a strong chance the stability will not be great.

- Someone Changed the Input and Read or Span Adjustment – If the Meter has a menu system that can easily be accessed, we have seen numerous meters programmed to numbers that make it look like a completely different system. Typically, we find someone trying to adjust the Meter or entering values incorrectly.

- A technician missed something – We are all human. There might be a special note on how the load cell should be loaded that was missed because it’s not standard. If you have historical data showing a very stable load cell, which is deemed not to be faulty, meaning meter or load cell, chances are something during calibration was missed.

Other Articles ASTM E74 Change From Previous

We have written two other articles regarding load cell stability and reliability. These may be beneficial in understanding why it is vital to purchase quality equipment.

Overall, investments in good load cells and meters pay huge dividends when one can demonstrate reliability.

Often, these systems result in fewer calibration surprises, lower measurement uncertainties, and less rework.

Our article on how a high ASTM E74 Change From Previous can kill your overall measurement uncertainty budget can be found here.

The other paper discusses how the proper indicator and load cell combination can result in fantastic reliability and is found here.

ASTM E74 Change From Previous Conclusion

In conclusion, a high ASTM E74 Change From Previous during force instrument calibration can be attributed to various factors outlined in the discussion.

Issues such as differences in cable length, the use of different adapters, variations in loading techniques, overloading or damage to the load cell, the inherent quality of the load cell and Meter, adjustments made to input and read values, and potential oversights by technicians all play a role in influencing calibration results.

Addressing these factors systematically and adhering to the guidelines provided in the ASTM E74 standard is crucial for maintaining accuracy and reliability in force measurements.

Investing in high-quality equipment, including load cells and meters, is a beneficial strategy, leading to fewer calibration surprises, lower measurement uncertainties, and improved overall reliability.

The importance of understanding and mitigating the causes behind a high ASTM E74 Change From Previous is emphasized, as it directly impacts measurement uncertainty budgets and ensures the consistent performance of calibration systems.

The provided insights and recommendations aim to assist in resolving calibration challenges and promoting the long-term stability and reliability of force and torque instruments.

References:

Standard practices for calibration and verification for force-measuring instruments. (n.d.). https://www.astm.org/e0074-18e01.html

Henry Zumbrun, President of Morehouse Instrument Company

About Morehouse Instrument Company

Companies worldwide rely on Morehouse for accuracy and speed. The company turns around equipment in 7-10 business days so customers can return to work quickly and save money.

The York, PA-based company provides force and torque measurement products and services worldwide.

Morehouse Instrument Company, a trusted and accredited provider of force and torque measurement services for over 100 years, offers measurement uncertainties 10-50 times lower than the competition.

Morehouse helps commercial labs, government labs, and other organizations lower their measurement risk by lowering equipment uncertainties for torque and force measurement. Contact Morehouse at info@mhforce.com .

More Information about Morehouse

We believe in changing how people think about force and torque calibration in everything we do.

This includes setting expectations on load cell reliability and challenging the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition.

We turn around your equipment in 7-10 business days so you can return to work quickly, saving you money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff.

Our YouTube channel has videos on various force and torque calibration topics here.