Proving Rings vs. Load Cells — Definitions, Accuracy, and a Practical Comparison.

After teaching many classes for NCSLI, ASQ, and other force measurement programs, one question always seems to come up: Which is better—Proving Rings vs. Load Cells? Instead of giving a one-sided answer, the following section takes a closer look at both options. The goal is to give you clear, straightforward information so you can decide which option best suits your needs.

What Is a Load Cell?

A load cell is a force transducer that converts mechanical force into an electrical signal, typically using bonded strain gauges arranged in a Wheatstone bridge. As force is applied, tiny elastic deformation changes the bridge output, which an indicator converts to engineering units (lbf, N, etc.). Modern indicators can apply multi-point linearization or polynomial coefficients (Morehouse 4215 Plus, C705P), so the display reads direct force. Many reference ("master") load cells include temperature compensation networks and pair with high-resolution meters for very low uncertainty.

What Is a Proving Ring?

A proving ring is a precision elastic ring that deflects under load. The deflection is measured with a micrometer/dial (analog) or displacement sensor (digital, Mitutoyo LGF series) and converted to force via the ring’s calibration equation (often polynomial). Because deflection depends on the ring’s elastic modulus and setup, proving rings require a more disciplined technique and explicit corrections for tare (fixtures/preloads) as well as the temperature at the ring, as the temperature will change with multiple cycles.

Note: More information on the tare load correction formula can be found here.

Proving Rings vs. Load Cells Tare & Temperature — The Practical Difference

Proving Ring

- Tare: Any preload from fixtures/adapters must be mathematically corrected using the ring’s coefficients whenever it is significant.

- Temperature: The calibration is valid at the stated calibration temperature to which it has been corrected. If the temperature of the proving ring differs, apply the temperature correction or include the effect explicitly in the uncertainty budget.

- Operator factors: Analog rings add dial/micrometer reading effects that typically make the Type A uncertainty component about 30 % more than a digital ring. An electric read vibrator will add even more uncertainty, as it is harder to hear when contact is first made with the reed and ball. Digital rings are far superior, though even with digital rings, the correct entry of coefficients and environmental conditions is essential.

Load Cell

- Tare: Press TARE on the indicator to zero fixtures and proceed. If the tare is unusually large, you should either confirm performance across the intended range or calibrate to the elevated span. When the tare is less than one percent of the ring’s capacity, the error is typically minimal, usually under 10 ppm. At a tare of two percent of the ring’s capacity, the error may increase to about 15–20 ppm. Even at five percent of the load cell’s capacity, the error is generally still under 100 ppm.

- Temperature: Bridge compensation and published coefficients minimize thermal influence; users budget the small residuals—no hand-applied temperature equations for routine work.

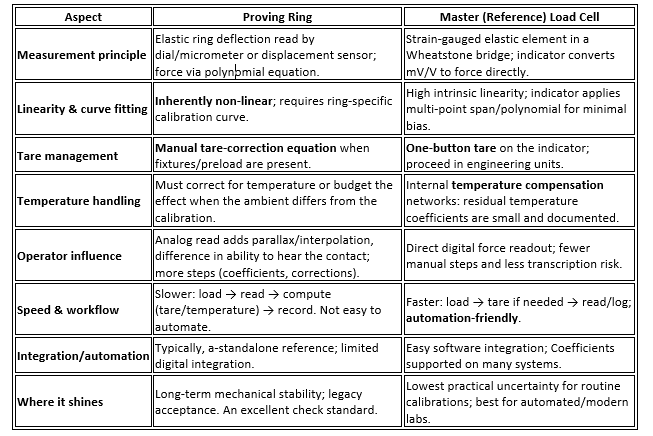

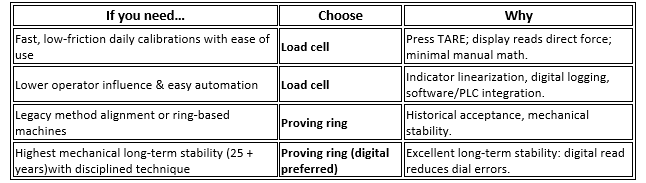

Detailed Comparison — Proving Rings vs. Load Cells (Master (Reference) Load Cell)

Decision Guide

Best‑Practice Notes

For Proving Rings

- Record temperature, ring coefficients, dial/readout details, and any tare corrections used.

- Prefer Morehouse digital conversions or Digital Rings with readouts to reduce reading error.

- Apply temperature and tare corrections (or carry them in the MU) whenever conditions differ from calibration.

For Load Cells

- Use proper alignment adapters and a matched indicator; load polynomial/ span points if provided.

- Tare electronically; if a large tare is unavoidable, reduce fixture mass or calibrate to the elevated span.

- Control temperature and allow thermal equilibrium; include the published temperature specification in the MU analysis as needed.

Why Master Load Cell Technology Is Better Than Proving Ring Technology (Accuracy)

- Lower practical error/uncertainty in day-to-day use when paired with a modern indicator and proper adapters. Polynomial linearization minimizes bias, so the meter reads direct force. (Proving Rings will not read nominal force)

- Built‑in temperature compensation reduces zero/span drift versus ambient changes; residual temperature effects are small and handled in the uncertainty budget.

- Simple, reliable tare handling: Press the meter’s TARE/NET to null fixtures and adapters—no manual curve math. For large tare, verify span or calibrate to the higher span.

- Higher reproducibility with proper fixturing: Spherical and alignment adapters reduce sensitivity to slight misalignment, improving repeatability/reproducibility over flat-to-flat loading.

- Less operator influence: The indicator displays force directly; no dial read, interpolation, or hand-applied polynomial entries (and the transcription errors that come with them).

- Standards‑aligned uncertainty methods: Reference load cells fit seamlessly into ASTM E74/ISO 376 methods with clearly specified contributors (resolution, temperature, side load, etc.).

- Overload: Most load cells can withstand a 150 % overload, while proving rings will require rework at about 120 % overload.

Proving Rings vs. Load Cells Conclusion

For most applications, a master load cell with a modern indicator provides the best combination of accuracy, speed, and robustness. Proving rings remain highly capable references—especially in legacy contexts—yet require explicit tare and temperature corrections and tighter operator discipline to match the practical performance of today’s load‑cell systems.

Analog Proving Rings require even more operator training and increase calibration cycle time. If you have decided to use a Morehouse Proving Ring, make it a digital one. Otherwise, strongly consider the benefits of load cells. Calibration intervals are going to be about the same, the only difference is a proving ring will likely last 25 + years, we have several that have lasted well over 60 years, though the overall cost of a Proving Ring, is more than double that of a load cell, and good load cells should likely have a lifespan of half that of a proving ring anyway.

Q1: What’s the main difference between proving rings vs. load cells?

A Proving Ring measures force by the amount its precision ring deflects, which is read with a dial or displacement sensor and converted using calibration equations.

A Load Cell measures force by converting strain in its elastic element into an electrical signal, which a digital indicator translates directly into force units.

Q2: Which is more accurate in practice?

Load cells generally offer lower day-to-day uncertainty because of built-in temperature compensation, digital readouts, and easy tare handling. Proving rings can be very accurate, but only when corrections for tare (fixtures/preload) and temperature are carefully applied, and the operator uses consistent technique.

Q3: How do I handle tare (fixtures or preload) in proving rings vs. load cells?

Proving Ring: You must apply a mathematical correction using calibration coefficients every time significant tare is present.

Load Cell: Just press the TARE button on the indicator to zero the fixtures and continue.

Q4: What about temperature effects?

Proving Ring: Calibration is valid only at the stated calibration temperature. If conditions differ, you must apply temperature corrections or include them in your uncertainty budget.

Load Cell: Temperature compensation is built into the strain gauges and bridge circuits. Small residual effects are included in published specifications.

Q5: Which one is faster and easier to use?

Load cells are faster and more automation-friendly. They provide a direct digital readout in engineering units, making daily calibrations more efficient. Proving rings require manual readings, corrections, and more operator training, which slows the process.

Q6: Where do Proving Rings still shine?

They have excellent long-term mechanical stability (25+ years, sometimes over 60).

They are widely accepted in legacy test setups and can serve as reliable check standards.

Digital proving rings reduce operator error compared to older analog dial types.

Q7: What about overload protection in proving rings vs. load cells?

Load cells often withstand up to 150% overload without damage. Proving rings usually require rework at about 120% overload.

Q8: Which option is more cost-effective long term?

Proving Rings: Higher initial cost, but they last much longer if properly maintained.

Load Cells: Lower upfront cost, but shorter lifespan (often half that of a proving ring). Still, for most labs, efficiency gains outweigh the longevity factor.

Q9: Bottom line—Which one should I choose?

If you need speed, automation, and lower operator influence, choose a Load Cell.

If you value long-term mechanical stability or must align with legacy methods, a Proving Ring—preferably digital—may be the right choice.

More Information about Morehouse

We believe in changing how people think about Force and Torque calibration in everything we do, including discussions on force calibration procedures

This includes setting expectations and challenging the "just calibrate it" mentality by educating our customers on what matters and what may cause significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition, providing you with more accuracy and precision in force measurement.

We turn around your equipment in 7-10 business days so you can return to work quickly and save money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Through Great People, Great Leaders, and Great Equipment, we empower organizations to make Better Measurements that enhance quality, reduce risk, and drive innovation.

With over a century of experience, we're committed to raising industry standards, fostering collaboration, and delivering exceptional calibration solutions that build a safer, more accurate future.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff. We have many more topics other than expressing SI units!

Our YouTube channel has videos on various force and torque calibration topics here.

#Proving Rings vs. Load Cells