What is Static Error Band (SEB)?

Almost any load cell specification sheet has a term called static Error Band. The term itself can be used to describe one of many accuracy specifications found on a load cell specification sheet.

This particular article hopes to explain what the term Static Error Band is.

Load Cell Accuracy: Simple Definition of Static Error Band

In a simplistic sense, the term static error band on a load cell specification sheet shows how much the load cell's output can vary when the same force is applied, and nothing changes.

It combines different types of errors, like small changes in readings when the weight is the same or when the load cell doesn't return exactly to zero after removing the weight.

The static error band helps people understand how accurate the load cell is when it's not moving or changing.

The smaller the error band, the more accurate the load cell is.

Load Cell Accuracy: Real Definition of Static Error Band

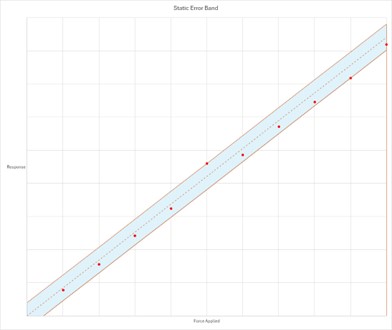

Static Error Band (SEB), % R.O.: The band of maximum deviations of the ascending and descending calibration points from a best-fit line through zero output.

This represents a subset of errors in the load cell’s output, including sources such as non-linearity, hysteresis, and return to zero after loading.

A lower SEB means higher accuracy.

For example, the static error band for smaller capacities is ±0.02 % R.O., meaning the error is within 0.02 % of the rated output (R.O.).

Author's note: If the load cell is always used to make ascending and descending measurements, this term best describes the load cell's actual error from the straight line drawn between the ascending and descending curves.

If the load cell is used for ascending measurements and, on occasion, descending measurements are needed, the user may want to evaluate Non-Linearity and Hysteresis separately, as those two definitions may provide a more accurate depiction of the load cell's performance.

How to calculate Static Error Band (SEB)

Our goal is to find a line that results in the smallest, maximum error.

This line also needs to fit through the origin (0, 0), so only the slope needs to be calculated via (y1+y2) / (x1+x2).

The best approach to this is to iterate across every pair of percent force applied of full scale (% FS) and the zero adjusted responses.

For each pair, calculate the slope, use the slope to calculate the percent error for all % FS, and take the largest error as that slope's "absolute error" value.

Repeat this for all possibilities, taking the slope that has the smallest absolute error value.

Code to calculate Static Error Band in Excel

Excel Macro Snippet

' Iterate across every permutation of 2 points

For i = 0 To N - 1

' Start at i + 1 to duplicating work, reducing iterations

For j = i + 1 To N - 1

' Prevent checking the same point and dividing by zero

If i <> j And PercentFS(i) + PercentFS(j) <> 0 Then

'tempSlope = (Vj + Vi) / (Rj + Ri)

maxError = 0

tempSlope = (Responses(j + 2, 1) + Responses(i + 2, 1)) / (PercentFS(j) + PercentFS(i))

' Ensure we don't accidentally set the minimum error to 0 or divide by 0

If tempSlope <> 0 Then

For k = 0 To N - 1

tempError = (Responses(k + 2, 1) - tempSlope * PercentFS(k)) / tempSlope

' Take the largest error for this slope

If Abs(tempError) > Abs(maxError) Then

maxError = tempError

slope = tempSlope

End If

Next k

' Find the slope that provides the lowest maximum error

If IsNull(minError) Or Abs(maxError) < Abs(minError) Then

minError = maxError

sebSlope = slope

End If

End If

End If

Next j

Next i

Load Cell Accuracy: Static Error Band (SEB) Shortcomings

If the load cell is used for ascending measurements and, on occasion, descending measurements are needed, the user may want to evaluate Non-Linearity and Hysteresis separately, as those two definitions may provide a more accurate depiction of the load cell's performance.

What needs to be avoided is a situation where a load cell is calibrated following a standard such as ASTM E74 or ISO 376, and additional uncertainty contributors for Non-Linearity and Hysteresis are added. ASTM E74 has a procedure and calculations that, when followed, use a method of least squares to fit a polynomial function to the data points.

The standard uses a specific term called the Lower Limit Factor (LLF), which is a statistical estimate of the error in forces computed from a force-measuring instrument's calibration equation when the instrument is calibrated following the ASTM E74 practice.

Load Cell Accuracy: What is Static Error Band (SEB)? - Conclusion

In conclusion, the Static Error Band (SEB) is a crucial parameter for understanding the overall accuracy of a load cell, particularly when the cell is subjected to both ascending and descending force measurements.

SEB provides a clear picture of the load cell’s precision by combining errors like non-linearity and hysteresis into one measurable range.

SEB serves as the best indicator of performance for applications where both upward and downward measurements are consistently taken.

However, in specific use cases, where only one type of measurement predominates, users may want to separately consider non-linearity and hysteresis for a more nuanced understanding of the load cell’s behavior.

Ultimately, understanding SEB helps ensure that the load cell performs reliably and meets the required accuracy standards for any given application.

More Information about Morehouse

We believe in changing how people think about force and torque calibration in everything we do.

This includes setting expectations and challenging the "just calibrate it" mentality by educating our customers on what matters and what may cause significant errors, such as not understanding what Static Error Band (SEB) is.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition, providing you more accuracy and precision in force measurement.

We turn around your equipment in 7-10 business days so you can return to work quickly and save money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Through Great People, Great Leaders, and Great Equipment, we empower organizations to make Better Measurements that enhance quality, reduce risk, and drive innovation.

With over a century of experience, we’re committed to raising industry standards, fostering collaboration, and delivering exceptional calibration solutions that build a safer, more accurate future.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff. We have many more topics other than expressing SI units!

Our YouTube channel has videos on various force and torque calibration topics here.

# Load Cell Accuracy: Static Error Band