TUR and Picking the Right Load Cell Distributor (UPC vs. PC vs. Calibration Cells)

The Question That Keeps Coming Up

A customer recently asked:

“The quote earlier was for Ultra-Precision load cells. Do we need to go for that grade to calibrate devices known to within 0.1 %, or is there an alternate model that could still give us acceptable TUR?”

That’s the question most labs face when budgeting for force calibration equipment. The answer depends not on brand or preference, but on what happens in the denominator of the TUR equation.

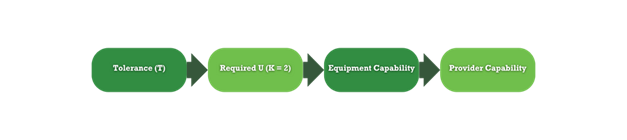

We ran another article called Start with the End in Mind, in which knowing the tolerance of what you need to calibrate is the first step. Then, you can work through determining your calibration and measurement capability, selecting the equipment (such as various Morehouse load cells), and ensuring the calibration provider has the appropriate capability to achieve the lowest possible measurement uncertainty for that equipment.

Essentially, you must account for the measurement uncertainty provided by your calibration provider; this serves as a good starting point. If you need a measurement uncertainty of 0.02 %, your calibration provider likely has to be at least five times better.

This article focuses on the Measurement Uncertainty for your Calibration and Measurement Capability (CMC), which includes the calibration provider you use, the load cells you purchase, and influences from the machines you use and the devices that are submitted to you for calibration.

1. What TUR Really Is—and Why It Matters

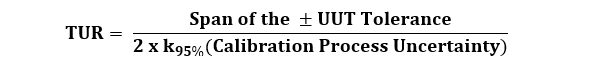

The Test Uncertainty Ratio (TUR) defines how capable your measurement process is compared to the tolerance of the unit you’re calibrating. According to ANSI/NCSLI Z540.3, TUR is:

The Test Uncertainty Ratio (TUR) defines how capable your measurement process is compared to the tolerance of the unit you’re calibrating. According to ANSI/NCSLI Z540.3, TUR is:

TUR is commonly used as a simplified approach of evaluating global risk. When we know the tolerance we are working to, we have a sufficiently large sample size to determine the shape and distribution of the calibration results and our end-of-period reliability. We can calculate the appropriate uncertainty that corresponds to the maximum amount of false accept risk we are willing to accept.

2. The Denominator: What’s Actually Inside

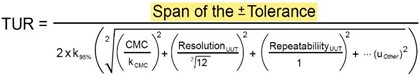

The denominator—sometimes referred to as the Calibration Process Uncertainty (CPU)—is not just your reference’s stated CMC. It includes every relevant contributor that affects the calibration result

Per the ANSI/NCSL Z540.3 Handbook, "For the denominator, the 95 % expanded uncertainty of the measurement process used for calibration following the calibration procedure is to be used to calculate TUR. The value of this uncertainty estimate should reflect the results that are reasonably expected from the use of the approved procedure to calibrate the M&TE. Therefore, the estimate includes all components of error that influence the calibration measurement results, which would also include the influences of the item being calibrated, except for the bias of the M&TE. The calibration process error, therefore, includes temporary and non-correctable influences incurred during the calibration, such as repeatability, resolution, error in the measurement source, operator error, error in correction factors, environmental influences, etc." [1]

The ANSI/NCSLI Z540.3 Handbook specifies that the denominator must include:

- The CMC component of the reference measurement system,

- The resolution of the UUT,

- Repeatability (Type A variation),

- Environmental factors (temperature, alignment, stability),

- Operator and procedural effects, and

- Any temporary or non-correctable errors observed during calibration.

ILAC P14:09/2020 clarifies this directly:

“Contributions to the uncertainty stated on the calibration certificate shall include relevant short-term contributions during calibration and contributions that can reasonably be attributed to the customer’s device.”

This means the denominator—the “U” in your TUR—represents everything that can influence the calibration result at that point in time. Ignoring contributors like resolution or repeatability can create a false sense of capability and shift risk downstream.

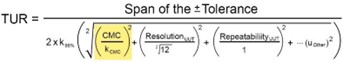

3. Why CMC Alone Isn’t Enough

Some calibration providers simplify the denominator to only the reference standard’s CMC. That’s not valid per the definitions in ANSI/NCSLI Z540.3 or ILAC G8:09/2019.

Here’s why:

The CMC is the best-case uncertainty your lab can achieve using its best measurement system and the best possible device.

But your customer’s unit isn’t the best device. It has its own resolution, repeatability, and environmental sensitivity that increase uncertainty during calibration.

When those contributors are ignored, the denominator becomes artificially small, inflating the TUR. That leads to incorrect conformity statements and a higher Probability of False Accept (PFA)

4. How Different Load Cells Change the Denominator

The CMC portion of the denominator depends heavily on the load cell’s grade, design, and calibration method.

Here’s how the three main classes differ:

| Load Cell Type | Typical CMC (k=2) | Description | Overall Denominator Impact includes Some UUT Estimates |

| Ultra-Precision (UPC) | 0.01 -0.02 % | Highest stability, reproducibility, and repeatability, calibrated with deadweight primary standards up to 120,000 lbf at Morehouse. | Minimizes the CMC portion of the denominator; ideal when the UUT dominates only slightly. |

| Precision (PC) | 0.02 -0.04 % | Very good stability, reproducibility, and repeatability, calibrated with deadweight primary standards up to 120,000 lbf at Morehouse. | Will likely increase the denominator by 1.4 -2 x on good equipment |

| Calibration-grade (C) | 0.040–0.06 % | Working standards are used for production verification. | It can have a significant impact on the denominator and is typically 2.5 – 3.5 times higher than UPC load cells

|

Note: These numbers are estimates; they can be calculated if you know the overall contributions of what you are testing, as well as calibration frequency, the number of standard changes, or transducers used. For Example, a UPC cell can maintain 0.02 % CMC from 20 % of capacity through full scale on a Morehouse Automated UCM with the right meter, though most might choose to run the cell down to 10 % of its capacity, and MU might become higher.

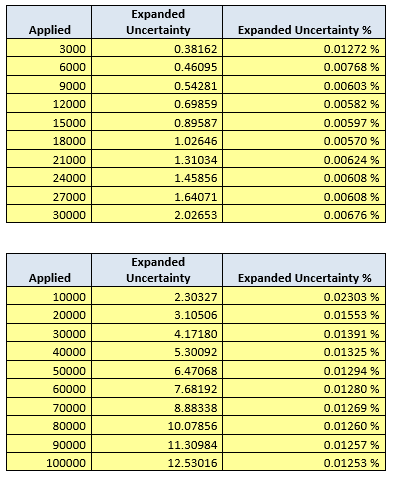

Below is an example of a 30 k load cell and a 100 k load cell.

These budgets are both for UPC cells, and the Expanded Uncertainties do vary a bit. The 30k has much better stability than the 100k load cell. All of this plays into that CMC portion of the denominator.

You can think of the denominator like a stack of uncertainty components. The CMC term is one layer, but so are resolution and repeatability. When you use a better load cell (lower CMC), you can improve one component of several. If the UUT’s own uncertainty is large, that improvement can get buried under other contributors.

5. Example: The Effect of Load Cell Class on TUR

Let’s take a 10,000 kg capacity system with ±0.10 % tolerance.

| Load Cell | CMC (k=2) | Resolution & Other Contributions | Expanded U | TUR |

| UPC | 0.010 % | Moderate (0.005 %) | 1.15 | 8.7 |

| PC | 0.020 % | Same | 2.08 | 4.8 |

| Calibration | 0.040 % | Same | 4.0 | 2.5 |

Now add a “poor UUT” scenario—coarse resolution and inconsistent readings. The denominator swells due to resolution and repeatability, while the CMC contribution becomes proportionally small. Suddenly:

| Load Cell | CMC (k=2) | Added Contributors | Expanded U | TUR |

| UPC | 0.010 % | +0.05 % (UUT effects) | 6.5 | 1.5 |

| PC | 0.020 % | +0.05 % | 6.8 | 1.5 |

| Calibration | 0.040 % | +0.05 % | 7.0 | 1.43 |

In this case, using a higher-grade load cell changes little—because the UUT dominates the denominator.

That’s why we say:

You can buy a better cell to lower your CMC, but it won’t help if your process or UUT drives uncertainty.

6. What You Can Control—and What You Can’t

When optimizing TUR, you control the measurement process, not the UUT’s inherent characteristics. Focus on reducing contributors in the denominator that belong to the system:

You can control:

- Reference CMC (use better cells, better indicators, or more load cells)

- Environmental stability (temperature, alignment, vibration)

- Repeatability of setup

- Operator technique

- Proper adapters and loading alignment

You can’t control:

- UUT resolution (it’s fixed)

- UUT internal hysteresis or design limits

- End-user tolerance definition

If you’ve minimized your controllable components, then moving from a PC to a UPC makes sense—because it’s the most effective way to reduce the CMC part of the denominator.

7. Using Multiple Load Cells to Improve the Denominator

You can also improve the denominator by spreading your range across multiple cells:

- Better range coverage keeps each calibration near its optimal operating point.

- Interpolation errors shrink when you avoid working too low in the range.

For example, use a 1,000 lbf cell for low forces and a 10,000 lbf cell for high forces, rather than a single 10,000 lbf cell for everything. That reduces CMC and process variability simultaneously, tightening the denominator and improving TUR.

8. When a Better Cell Really Matters

UPC load cells pay off when:

- The UUT has fine resolution and repeatability.

- TUR targets are high (≥4:1).

- Process uncertainty dominates the denominator.

- Decision rules like Method 6 (Z540.3) require PFA < 2 %.

PC load cells are best for:

- Calibrating analog or moderate-tolerance devices.

- When environmental and repeatability effects already exceed 0.02 %.

Calibration-grade cells are best for:

- Routine production verification or field checks (TUR ≈ 2:1–3:1).

- Scenarios where UUT behavior dominates uncertainty, making lower CMC irrelevant.

9. Why It’s About Risk, Not Just Ratio

The purpose of TUR isn’t to chase numbers to control measurement risk. A TUR of 4:1 means you can make a confident pass/fail decision with a low risk of false acceptance, but only if the denominator is calculated correctly.

A correct TUR denominator ensures that global consumer risk—the risk that a nonconforming product is accepted—stays within acceptable limits across the traceability chain.

10. Bottom Line

- The TUR numerator (tolerance) is easy.

- The denominator (expanded uncertainty of the entire calibration process) is what separates good metrology from risky shortcuts.

- You can reduce the denominator by using better load cells (lower CMC), multiple ranges, and controlled processes—but if the UUT dominates, upgrading the reference won’t help.

- The right cell depends on what drives your denominator, not just the ratio on paper.

In the end, the goal isn’t to meet an arbitrary TUR ratio—it’s to ensure that your measurement results are trustworthy and that your conformity decisions truly reflect the risk.

Morehouse has a spreadsheet for anyone wanting to use different scenarios. This sheet will tell you how good your reference CMC needs to be to hit a specific TUR ratio.

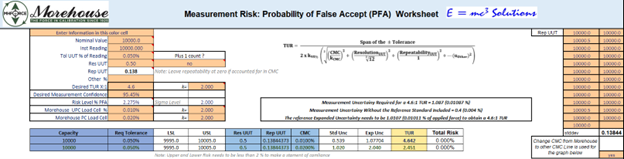

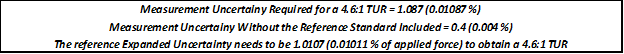

Appendix Worked Example Using the Morehouse Spreadsheet that can be downloaded here.

In this example, let us suppose we are calibrating a 10,000 lbf device with a tolerance of ± 0.05 % of full scale. The device has a resolution of 0.5 lbf, and we have run repeatability studies showing that the standard deviation of repeat measurements runs around 0.138 lbf.

Scenario

You are calibrating a 10,000 lbf device with a tolerance of ±0.05 % of full scale.

- Full scale (FS): 10,000 lbf

- Tolerance = 0.0005 × 10,000 = ±5.0 lbf

- Device resolution: 0.5 lbf

- Repeatability: standard deviation of repeats = 0.138 lbf (already a standard uncertainty)

- Compare two reference options for the calibration system’s CMC (k≈2):

- Calibration Grade Morehouse Load Cell©: 0.02 % of reading (k=2)

- Precision Grade Morehouse Load Cell (PC): 0.01 % of reading (k=2)

- Ultra-Precision Grade Morehouse Load Cell (UPC): 0.005 % of reading (k=2)

We’ll compute the denominator of TUR as the expanded uncertainty of the calibration process (k≈2), including: reference CMC, resolution, and repeatability. (You can add other contributors—environment, alignment, adapters—if needed.)

Step 1 — Convert contributors to standard uncertainties

Reference CMC → standard (u_ref):

- Calibration Grade (C): 0.02 % of 10,000 lbf = 2.0 lbf (k=2) →

- Precision Grade (PC): 0.01 % of 10,000 lbf = 1.0 lbf (k=2) →

- Ultra-Precision (UPC): 0.005 % of 10,000 lbf = 0.5 lbf (k=2) →

Resolution (digital):

Resolution step = 0.5 lbf, assume uniform distribution:

Repeatability (already standard uncertainty):

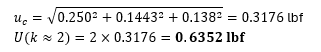

Step 2 — Combine (RSS), then expand (k≈2)

For each reference option:

A) Calibration Grade (CMC = 0.02 % of reading, k=2)

B) Precision Grade (CMC = 0.01 % of reading, k=2)

C) Ultra-Precision Grade (CMC = 0.005 % of reading, k=2)

Note: We are using the specification sheet values; the actual CMCs will likely be higher as additional Measurement Uncertainty Contributors will be included that are not included here, such as reference standard stability, repeatability tests, and more. These values are shown as a best-case scenario to explain the concept.

Step 3 — Compute TUR = Tolerance / U

| Reference Grade | Expanded U (lbf) | TUR (Tol ÷ U) |

| Calibration (C, 0.02 %) | 2.0395 | 2.45 : 1 |

| Precision (PC, 0.01 %) | 1.0768 | 4.64 : 1 |

| Ultra-Precision (UPC, 0.005 %) | 0.6352 | 7.87 : 1 |

Interpretation

- Reducing CMC from 0.02 % → 0.005 % produces a substantial improvement: 2.45 : 1 → 7.87 : 1.

- The Ultra-Precision load cell moves the process well beyond the 4:1 TUR benchmark, offering significant margin and risk reduction.

- At this fine resolution (0.5 lbf), the reference CMC is the limiting factor, so upgrading the reference directly improves TUR.

- For coarser-resolution devices, the benefit would taper off as resolution becomes the dominant contributor.

Now, if we changed the resolution of the UUT to 5 lbf and ran the same calculations the difference between a UPC and PC load cell would not be nearly as dramatic

Comparing Three Morehouse Load Cells with various resolutions of the UUT.

Calibration (0.02 % → 2 lbf @ k≈2 → lbf)

| Resolution UUT (lbf) | Expanded U (lbf) | TUR (Tol ÷ U) |

| 1 | 2.100 | 2.38 : 1 |

| 2 | 2.326 | 2.15 : 1 |

| 5 | 3.523 | 1.42 : 1 |

PC (0.01 % → 1 lbf @ k≈2 → lbf)

| Resolution UUT (lbf) | Expanded U (lbf) | TUR (Tol ÷ U) |

| 1 | 1.187 | 4.21 : 1 |

| 2 | 1.552 | 3.22 : 1 |

| 5 | 3.067 | 1.63 : 1 |

UPC (0.005 % → 0.5 lbf @ k≈2 → lbf)

| Resolution UUT (lbf) | Expanded U (lbf) | TUR (Tol ÷ U) |

| 1 | 0.812 | 6.16 : 1 |

| 2 | 1.288 | 3.88 : 1 |

| 5 | 2.943 | 1.70 : 1 |

Takeaways

- Resolution is the lever. Going from 5 → 2 → 1 lbf resolution markedly lifts TUR for all references.

- Higher-grade references help most when resolution is not a dominate MU contributor. At 1 lbf, moving C (0.02 %)→ PC(0.01 %) → UPC(0.005 %) improves TUR from 2.38 → 4.21 → 6.16.

- At coarser resolutions (e.g., 5 lbf), the UUT dominates the denominator, so lowering the reference CMC yields only modest gains.

- The same is true for UUT repeatability; if the device is not repeatable, it can dominate the denominator.

About Morehouse

We believe in changing how people think about Force and Torque calibration in everything we do, including discussions on Deadweight vs hydraulic force calibration machines.

This includes setting expectations and challenging the "just calibrate it" mentality by educating our customers on what matters and what may cause significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition, providing you with more accuracy and precision in force measurement.

We turn around your equipment in 7-10 business days so you can return to work quickly and save money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Through Great People, Great Leaders, and Great Equipment, we empower organizations to make Better Measurements that enhance quality, reduce risk, and drive innovation.

With over a century of experience, we're committed to raising industry standards, fostering collaboration, helping with understanding risk, and delivering exceptional calibration solutions that build a safer, more accurate future.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff. We have many more topics other than load cell distributors and TUR.

Our YouTube channel has videos on various force and torque calibration topics here.

# TUR # Load Cell Distributor