Force Calibration Lead Time Problems and 4 Ways You Can Avoid Them

We all deal with scheduling force calibration a little bit differently, and most of us struggle when our equipment is out for calibration. Imagine this scenario. The company we send our equipment to promises a turnaround time to meet our schedule. That date slips, we are not notified, and we start to feel like we are bothering them for updates.

At Morehouse, we have a 7-10 day calibration lead time. This article will examine the not-so-hidden cost of the downtime that most companies experience with calibration. We will review the challenges from the supplier's side and provide four ways you can help make sure your equipment is back in time.

This presumes that you use a reputable service provider like Morehouse. Our goal is 100 % on-time service. This does not always happen and many times we miss it because of something the customer did or did not do. First, we will cover the actual cost and pain of downtime.

Force Calibration Lead Time - Equipment Downtime

Some companies maintain several reference standards so they have a backup when equipment is sent out for calibration. If you do not, then you know the minor inconveniences or severe headaches that can result.

For example, your vendor promises a two-week turnaround for your equipment. Therefore, you add a one-week buffer and schedule the equipment to be used three weeks out. If you don’t have your equipment back after three weeks, then you have to reschedule on-site visits. You may also have equipment backing up in your lab and customers calling you for an update. Once your equipment is returned, maybe overtime is required to get through the backlog.

When a date slips, everyone along the supply chain can be affected. You may forget these headaches until it happens repeatedly.

To break this cycle, consider the actual costs associated with a missed calibration lead time. These can include:

- Rescheduled Work – How much does it cost to switch schedules around or reschedule someone from here to there? Is this impacting time, flights, or internal deadlines? How many people need to be notified, and how much money is spent in the shuffle? A simple calculation could include 15 minutes of my time for notifying a department of delays plus 15 minutes of anyone else's time to coordinate and reschedule. At 15 minutes, we can assume that we spend $ 5.00 for everyone we need to contact. Now multiply this by the number of people who are impacted throughout the company. We know it could take longer and the actual cost is likely more, but this gives us a starting point.

- Additional Overtime to "Catch-Up" – This is more straightforward because you will likely still pay employees while your equipment is away. What happens when the backlog grows? Overtime! Multiply the overtime wage by the amount of the backlog has grown because the equipment is not there on time.

- Lost Revenue – Did you lose revenue or potential revenue? Will you make it up? What is the value of that cash on hand or a more frequent payment in managing the income statement? Did you miss a target? If miss targets and schedule a meeting to discuss the issue, what is the cost of that meeting? Multiply those who would attend by their appropriate wages for the 30-90 minutes. This is time they lose from attending the meeting and being pulled off their everyday work.

- Lost Customers – A customer is upset because they need their equipment to do critical work and they are not okay with a delay. Customers do voice their concerns about delays with threats. What is the lifetime value of the customer? If we are being conservative, multiply the average billable dollars over the last three years and triple it. This assumes they would be a customer for at least another ten years. The estimated cost does not even account for increased pricing and spending.

- Reputation – No company wants to be known for overpromising and under-delivering. What does this cost as far as referrals and future growth? It is likely excruciating.

Why Can’t I Have a Fast Lead Time, Quality Service, and a Fantastic Price Point?

So you made it this far and hopefully have started to realize there are some large costs associated with delays. It might be time to shop for a new calibration provider. Your list may include a fast lead time, quality service, and a fantastic price point.

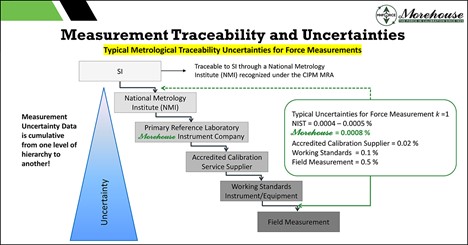

If a calibration lab does have all three, they will not last very long. They would be so busy that they could not keep up. Then in trying to keep up, they will miss dates, raise prices, or skimp on quality. The lack of quality will financially damage anyone quickly because calibrating instruments with a bad reference standard will impact anywhere from hundreds to thousands of instruments, depending on where you are on the pyramid.

If someone finds a calibration lab with all three, I can assure you there is an issue.

At Morehouse we put quality first, using deadweight reference standards with accuracies ten to twenty times better than most other calibration labs. We do contract reviews, educate our customers on what matters, and have discussions to give the best support we can and provide meaningful data. We then set a realistic lead time for equipment that is sent to us in working condition.

Our pricing is based on industry benchmarks. Other force calibration laboratories use standards with ten to twenty times higher uncertainty, which means they can do eight instruments in the same time it takes us to do one. However, we do not set price points 8 times higher. Our prices are 10 - 15 % higher on most instruments, which is anywhere from $ 50 to $ 500 more.

Comparing Hidden Cost with Upfront Cost

Now it is time for reflection. Is the $ 50 to $ 500 cost more than the hidden cost you calculated earlier? My guess is that it’s not! Someone may say, “We can schedule a month’s downtime and still save $ 50 to $ 500.” This is possible if you do not want to grow your calibration volume and the extra weeks of profit from not utilizing that equipment does not matter.

Perhaps you do not need a more accurate calibration and lead time does not matter. Maybe your employees are okay with just showing up to do a day's work, the company is profitable, and no one cares to make improvements. The average business used to survive at least five decades, but now they are lucky to survive a decade and a half. Many remain stagnant and will eventually fail. Is that what you or anyone in your organization wants?

Four Ways You Can Control Calibration Lead Time

There are some ways that a customer can increase the probability of a calibration provider meeting their promised lead time. This assumes the provider is trustworthy and performs quality work. Sticker slapping is not covered, though we know that some labs receive equipment, put on a sticker, and move on to the next unit.

You are still here? Great! Certain members of our team are going to start liking you a bit more after reading this section. Why? Because we struggle to meet deadlines when a customer does not:

- Verify the equipment is working correctly prior to sending. When equipment is received in non-working order, we can troubleshoot and fix most equipment. However, the resources it takes to do the work and order replacement parts can impact lead time. This may include getting approval on the repair cost or ordering parts with long or unknown lead times. There are many times when Morehouse can do a replacement faster and more cost-effectively than waiting on another manufacturer to send a replacement.

- Verify all the adapters, cables, and other needed pieces are in the shipping container. When equipment is sent in for calibration and missing adapters, we will contact you. The adapters and sometimes the cable is integral to the calibration. Calibrating a device with a different four-wire cable or top block, baseplate, and so on can change the load cell's output by as much as 1 – 2 % in extreme cases. Knowing that most of our customers want between 0.005 % - 0.1 % accuracy, an error of 10 to 200 times what is expected is not something we choose to send out. This is because we put quality above all else. Therefore, we will discuss a solution with the customer, and lead times will often slip.

- Be very clear on your expectations. We will ask questions to help you procure the right equipment. Although we do not know all makes and models, we do know most equipment and can give you guidance. For example, there is a manufacturer that says, “Oh, it is good to 0.1 % of applied,” and we have to say something like, “the resolution is so course that the resolution only makes it only good to 0.25 % at the 10 % force point.” Here is where we could have helped during the procurement of equipment. We sell force equipment, and if we do not have what you need, we are happy to give guidance to help avoid these situations. We hope we will be the calibration provider, in which case, this becomes a win-win for all.

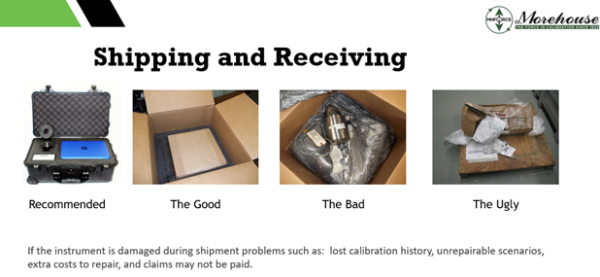

- Pack the Equipment Properly. The pictures below are good examples of best practices when sending equipment. If someone drops equipment, or a conveyor belt tears open a box, it is frustrating to everyone. There are many instances where a heavy load cell splits a cable, and a repair is needed. A heavy load cell placed on top of a delicate meter could break the meter, and the issue is revealed while unpacking the instrument. Morehouse builds custom cases all the time with high-density foam to help avoid these issues. The cost is typically $ 350 to $ 650. Yes, it is a lot of money. However, to properly package typically takes 3-4 hours of someone’s time and about $ 300 in material.

Force Calibration Lead Time - Conclusion

It should be simple, shouldn’t it? Lead times play a critical role in the supply chain around the world. When they slip or are longer than they need to be, the downstream impact can have cascading consequences on others and your bottom line. Recent feedback I gathered on price versus lead times revealed these important factors:

- Trust

- Customer service

- Reputation

- Problem-solving

- Realistic Measurement uncertainties

We know that having two sets of reference standards can safeguard downtime, but it adds considerable cost to the organization. The actual cost of several weeks of delayed lead time adds up to more than having an organization such as Morehouse take care of your force calibration needs. You and your calibration provider should be partners, discussing up-front the importance of adapters, alignment, and other factors that can impact your equipment and lead time.

Morehouse does not overpromise and under-deliver on our force calibration lead time. We work hard to ensure we meet high-quality standards, the promised delivery date, and a fair price.

Are you up against a deadline? Do you want a calibration provider that puts Quality first? Please, Contact Morehouse for quick calibration turnaround times to keep you on track and your overall costs down.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

# Force Calibration Lead Time