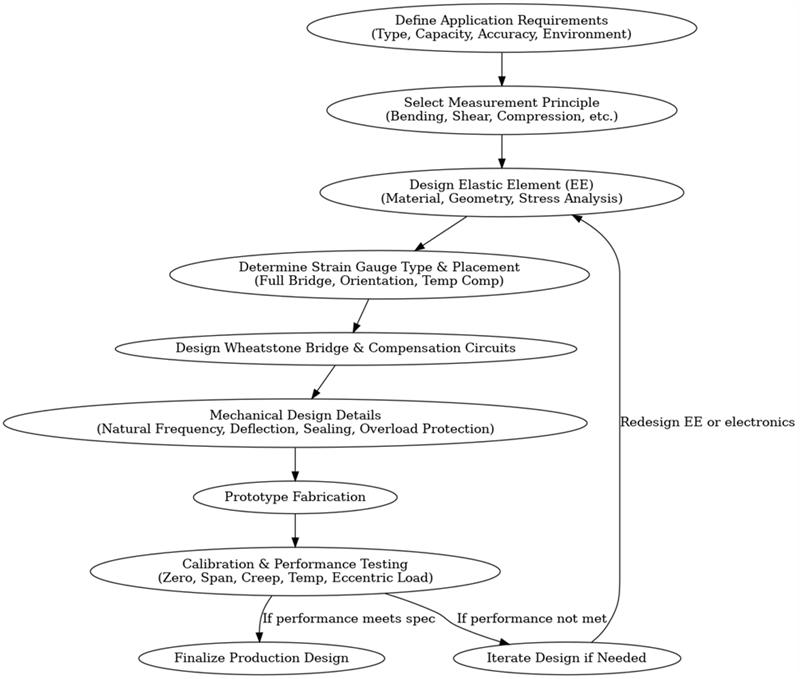

Morehouse Custom Load Cell Design: 10 Steps Encompassing Comprehensive Principles, Innovative Process, and Best Practice

Designing a reliable custom load cell starts long before metal is cut or gauges are bonded. It begins with a clear understanding of what is being measured, where the sensor will live, and how its signal will be used.

This post walks through that journey, from the fundamentals of how a load cell converts force into an electrical output to the practical decisions that determine performance in the field.

Along the way, we will translate requirements into a sensible measuring principle, shape the elastic element for useful strain, place and wire strain gauges for accuracy and stability, and build in the mechanical details that keep the device robust over time.

The goal is to help you make informed, defensible tradeoffs. Do you need bending sensitivity or side load immunity?

Higher output or lower creep? Compact packaging or greater stiffness?

We will show how to answer these questions with analysis, proven design rules, and thoughtful calibration.

Finally, we will highlight common pitfalls, such as poor gauge placement or overlooked installation effects, so you can avoid them before they become costly errors in the finished custom load cell.

By the end, you will have a practical framework for specifying, designing, and validating a custom load cell that balances sensitivity, robustness, and environmental resilience, ready to deliver trustworthy measurements in the real world.

1. Understanding What a Custom Load Cell Is

A load cell is a force transducer that converts mechanical force—compression, tension, or both—into an electrical signal, usually via strain gauges arranged in a Wheatstone bridge configuration.

The change in electrical resistance of the gauges is directly proportional to the mechanical strain, which is proportional to the applied force.

2. Defining the Design Requirements

Before starting any mechanical design, the application must define:

- Type of load: compression, tension, bending, shear, torsion, or multi-axis.

- Capacity range: maximum load to be measured with an adequate safety margin (safe load, ultimate load).

- Accuracy requirements: resolution, non-linearity, hysteresis, creep, temperature stability.

- Environmental conditions: temperature range, moisture, corrosion, vibration, shock loads.

- Form factor and installation constraints: available space, mounting method, cable routing, sealing.

3. Selecting the Measuring Principle

Common custom load cell principles and their uses:

- Bending beam – high sensitivity, low to medium capacity, easy gauge placement.

- Shear beam – good side-load resistance, medium to high capacity.

- Column – high capacity, but more sensitive to off-axis loads.

- Ring torsion – compact, good creep performance.

- Diaphragm/membrane – often used in low-profile compression sensors.

4. Choosing the Elastic Element Geometry

The elastic element (EE) is the “heart” of the custom load cell. It must:

- Deform elastically under rated load (below yield point, typically <1/3 yield stress for safety).

- Provide measurable strain in the gauge area without exceeding strain gauge limits.

- Be stiff enough to maintain natural frequency above application requirements

Selection involves:

- Shape optimization (beams, rings, diaphragms).

- Stress analysis (analytical or FEA) to locate maximum principal strain regions for gauge bonding.

- Material choice (tool steel, stainless steel, aluminum alloys) based on strength, modulus, machinability, and corrosion resistance.

Morehouse Custom Load Cell Ready for Gauging

5. Strain Gauge Selection and Placement

- Type: Foil strain gauges are most common; semiconductor gauges for high output; special coatings for harsh environments.

- Gauge orientation: align with principal strain directions (±45° for shear webs, longitudinal for bending beams).

- Number of gauges: Full Wheatstone bridge (4 gauges) improves sensitivity, temp compensation, and noise rejection

- Placement rules: Bond gauges in areas of uniform strain, avoid stress concentrations, and use symmetry to cancel bending or off-axis effects.

6. Wheatstone Bridge and Compensation Circuits

- Bridge completion: 4-16 active gauges + dummy gauges for temperature compensation.

- Compensation networks: resistors and temp-dependent elements to correct for:

- Zero drift with temperature.

- Span drift with temperature.

- Shielding and grounding: Prevent electrical noise pickup.

7. Mechanical Design Considerations

- Natural frequency: High enough to avoid resonance in dynamic applications.

- Deflection: Typically in the range of 0.1–1 mm at full scale—balance between sensitivity and robustness.

- Overload protection: Mechanical stops to prevent damage from shock or accidental overloading.

- Sealing: IP rating based on environment (elastomer boots, welded diaphragms, potted cavities).

- Cable entry: Strain relief to prevent damage during installation or service.

8. Calibration and Performance Testing

After fabrication:

- Zero balance check – ensure no-load output is within specification.

- Static calibration – apply known forces (deadweights, force standards) over full range, in both increasing and decreasing sequences.

- Creep test – measure output stability under constant load over time.

- Temperature tests – check zero and span shifts across the temperature range.

- Eccentric load test – evaluate sensitivity to off-axis forces.

9. Common Pitfalls to Avoid

- Gauge placement errors – leads to poor sensitivity or high non-linearity.

- Improper material heat treatment – can cause drift or creep.

- Ignoring installation effects – bolting, mounting surfaces, and adapters can alter strain distribution.

- Inadequate sealing – moisture ingress is a common cause of failure

Morehouse Custom Load Cell Finished and Tested

Morehouse Custom Load Cell Finished and Tested

10. Conclusion

Designing a custom load cell is a multidisciplinary task involving mechanical design, materials engineering, strain gauge technology, and electronic signal conditioning. A well-designed load cell balances sensitivity, robustness, and environmental resilience, while meeting the accuracy and capacity requirements of the application.

Following established design practices, using FEA for optimization, and performing rigorous calibration/testing ensures a reliable and accurate measurement device.

Morehouse Custom Load Cell Process

Over the past century, we’ve worked with thousands of customers, from small machine shops to global aerospace firms, and many have asked the same questions about custom load cells (that we have offered for 30 + years). Whether they’re looking to solve a unique measurement challenge, replace a discontinued product, or improve reliability, the concerns are remarkably consistent. Below are some of the most common questions we hear, along with straight answers based on decades of hands-on experience designing, building, and calibrating load cells for demanding applications.

FAQ

1) What types of load cells does Morehouse design and build?

Answer: Virtually all major architectures—bending and shear beams, columns/canisters, ring torsion, diaphragm/low-profile, S-beam/tension–compression, and multi-axis (force/torque). We also tailor materials (tool steel, stainless, aluminum), sealing, mounting, and connectors to the application, and can replicate or improve legacy designs when needed.

2) Will a custom load cell cost more than a standard one?

Answer: Not necessarily. A purpose-built design can eliminate expensive fixtures required by generic cells—often the fixtures cost 10× the load cell. Smaller custom manufacturers also tend to have lower overhead, making custom competitive even in small volumes.

3) Is a custom load cell less reliable?

Answer: No. A custom load cell typically receives extra scrutiny and testing. Many standard products get minimal production checks, with performance assumed from legacy designs; custom validation often reduces parts count, lowers risk, and increases overall reliability.

4) Do large corporate manufacturers have more expertise or move faster?

Answer: Not by default. Big firms often rely on decades-old standard designs and prioritize cost reduction, which can hinder innovation. Morehouse designs new load cells daily, engineers work directly with end users, and we prioritize delivery supported by 2–3 backup suppliers for key components to reduce supply-chain risk.

5) Can Morehouse replace or replicate another vendor’s load cell—even an older one?

Answer: Usually yes, and with original specifications, it’s often straightforward. Many vendors have changed ownership, reduced quality to cut costs, or discontinued older lines; a Morehouse replacement can match performance while improving reliability and support.

6) Will Morehouse meet government and aerospace requirements—and back up performance claims?

Answer: Yes. Morehouse has been a trusted government supplier since NIST selected us to produce early production proving rings in the 20th century, and we work daily with major aerospace quality teams to meet rigorous compliance. Our accredited force calibration lab is widely recognized, and competitors even send us their load cells when customers require independent, accredited test data.

More Information about Morehouse

We believe in changing how people think about Force and Torque calibration in everything we do, including discussions on force calibration procedures

This includes setting expectations and challenging the "just calibrate it" mentality by educating our customers on what matters and what may cause significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition, providing you with more accuracy and precision in force measurement.

We turn around your equipment in 7-10 business days so you can return to work quickly and save money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Through Great People, Great Leaders, and Great Equipment, we empower organizations to make Better Measurements that enhance quality, reduce risk, and drive innovation.

With over a century of experience, we're committed to raising industry standards, fostering collaboration, and delivering exceptional calibration solutions that build a safer, more accurate future.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff. We have many more topics other than expressing SI units!

Our YouTube channel has videos on various force and torque calibration topics here.

#custom load cell