How do I choose a Load Cell System? 4 Steps for Choosing the Right Load Cell Calibration System.

In metrology, force and torque measurements are vital across multiple industries, from aerospace to automotive to healthcare.

Achieving accurate measurements often depends on the careful selection of the full load cell calibration system.

Load cells, the core of force measurement systems, come in various forms and must be paired with appropriate indicators and calibration services.

Failure to choose the right combination can result in significant measurement inaccuracies, potentially affecting product quality, safety, and operational efficiency.

This blog explores the steps involved in choosing the right load cell calibration system, addressing load cell types, indicators, and the selection of calibration providers.

Additionally, the importance of managing measurement risk through correct calibration procedures and the role of adapters will be discussed.

Step 1: Choosing the Right Load Cell(s)

The first step in designing an accurate load cell calibration system is choosing the right load cell type. Load cells vary in design and function, and the selection should be driven by the application’s specific needs. Key types include:

- Column Load Cells: Known for their ability to handle high stress, these are commonly used in heavy-load applications but are sensitive to off-center loading and exhibit significant non-linearity.

- S-Beam Load Cells: These are typically used in tension applications, such as weighing systems. While compact, S-beam cells are sensitive to misalignment, which can lead to measurement errors.

- Button and Pancake Load Cells: These load cells are designed for applications where space is limited. However, their accuracy can be significantly impacted by misalignment if proper adapters are not used.

- Shear Web Load Cells: Offering low creep and high accuracy, these cells are typically the preferred choice for both field and laboratory calibration standards, particularly for forces ranging from 100 to 100,000 pounds-force (lbf).

Figure on Choosing the right load cell shows two Morehouse Shear Web options.

Figure on Choosing the right load cell shows two Morehouse Shear Web options.

Typically, if one is looking for the best performance, the shear web style load cells will be the top choice.

Step 2: Choosing the Right Indicator

The indicator is the device that converts the electrical signal from the load cell into a visual or numeric value.

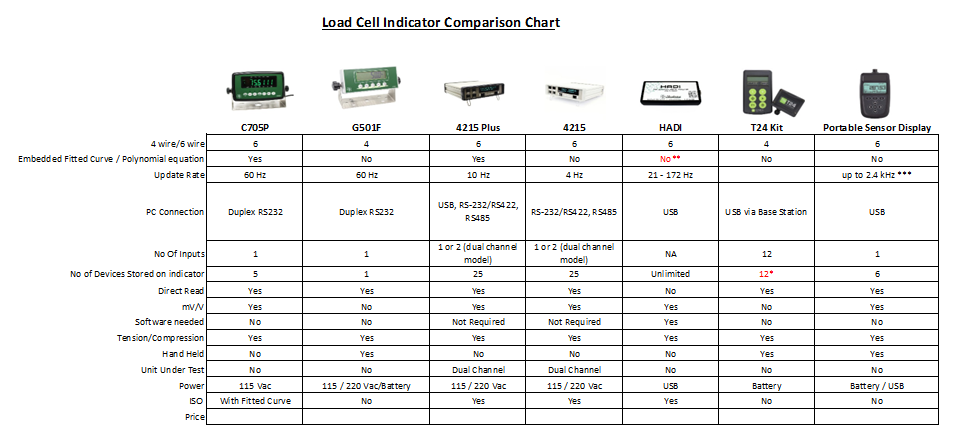

Choosing the right indicator involves several considerations:

- Accuracy Requirements: The indicator must have sufficient resolution and stability to meet the system’s accuracy demands. For high-precision applications, indicators capable of using polynomial coefficients such as the Morehouse 4215 plus, and C705P can significantly reduce measurement bias.

- Environmental Conditions: Depending on the application, it is crucial to select an indicator that can withstand the environmental conditions in which it will be used, such as temperature fluctuations or vibrations.

- Wired vs. Wireless Options: Depending on the system's mobility requirements, both wired and wireless indicators may be considered. Morehouse has several wired options and an easy-to-install wireless Bluetooth module that can plug directly into the load cell.

If you can use a computer and a laptop, our HADI system is likely the most reliable and offers optimum performance for the price.

Step 3: The Role of Adapters

Correct alignment is a critical factor in force measurement accuracy.

Load cells are often highly sensitive to misalignment and thread engagement issues.

The proper use of adapters can help mitigate these effects.

For example, spherical alignment adapters are commonly used in compression applications to ensure that forces are applied in the correct direction.

ISO 376, an international standard for force calibration, highlights the importance of adapters in ensuring reproducibility across different measurement conditions.

More information on adapters can be found in our Technical Paper on Recommended Compression and Tension Adapters for Force Calibration.

Step 4: Selecting the Right Calibration Provider

The final, yet most crucial step in choosing the right load cell, involves selecting a calibration provider.

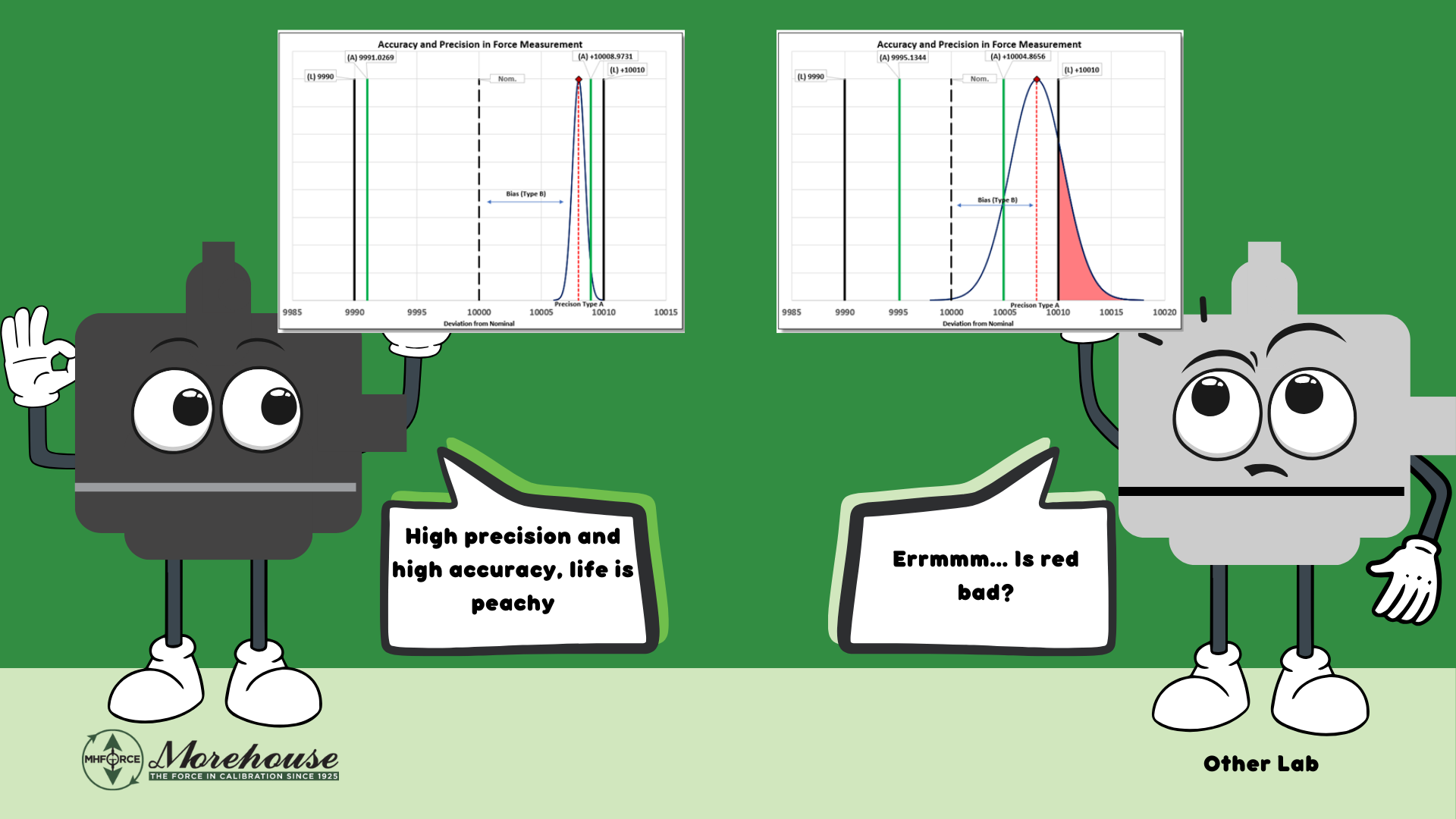

The accuracy of a load cell calibration is directly influenced by the capabilities and measurement uncertainty of the calibration laboratory.

Not all labs are equipped to handle high-precision force measurements, and not all can say something passes calibration when taking measurement uncertainty into account.

When evaluating providers, consider:

- Calibration and Measurement Capability (CMC): Laboratories with lower CMCs can provide more accurate calibrations with lower uncertainties. A good rule of thumb is to work with labs that offer CMCs as low as 0.002 % of the applied force for critical applications.

- Test Uncertainty Ratio (TUR): Ensure the calibration provider can deliver a TUR of 4.6:1 or greater, which minimizes the probability of false acceptance in measurement results.

- Accreditation and Standards Compliance: Laboratories should follow ISO/IEC 17025 standards and other standards, where applicable such as ASTM E74 and ISO 376 to ensure that uncertainties are correctly reported and accounted for in compliance statements.

Conclusion

Choosing the right load cell calibration system is a multifaceted decision involving the selection of load cells, indicators, adapters, and calibration providers.

Each element plays a crucial role in minimizing measurement uncertainty and ensuring that the system performs accurately under operational conditions.

By following the guidelines outlined in this article, companies can significantly enhance the accuracy of their force and torque measurements, reduce risks, and improve overall measurement reliability.

More Information about Morehouse

We believe in changing how people think about force and torque calibration in everything we do.

This includes setting expectations and challenging the "just calibrate it" mentality by educating our customers on what matters and what may cause significant errors in choosing the right load cell.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition, providing you more accuracy and precision in force measurement.

We turn around your equipment in 7-10 business days so you can return to work quickly and save money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Through Great People, Great Leaders, and Great Equipment, we empower organizations to make Better Measurements that enhance quality, reduce risk, and drive innovation.

With over a century of experience, we’re committed to raising industry standards, fostering collaboration, and delivering exceptional calibration solutions that build a safer, more accurate future.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff. We have many more topics other than choosing the right load cell.

Our YouTube channel has videos on various force and torque calibration topics here.

# Choosing the right load cell