5 Essential Facts About Torque Calibration

Torque Calibration is essential because almost any fastener has a specification for torque. The purpose is to maintain a clamping force where the fastener stays together and is as immune as possible to fatigue.

This article will discuss the five essential must-know facts about torque calibration. We will cover why torque calibration is necessary, the definition of torque, mass versus force, sensitivity to environmental conditions, and handling and storage issues.

Other torque calibration errors, like how to correct cosine errors, can be found here with our other blogs on torque calibration.

There are many other torque calibration error sources one should be aware of, which is why we have a YouTube video for people who want to learn more.

#1 Why is Torque Calibration Important?

Torque calibration is vital in the maintenance and quality assurance of torque tools, such as torque wrenches, screwdrivers, and other devices used in various industries.

Properly calibrated torque tools ensure accurate and consistent measurements, leading to higher quality and safety in applications ranging from automotive repair to aerospace manufacturing.

One standard method for torque calibration involves using mass weights. However, this approach has several drawbacks that can affect the accuracy and reliability of the calibration process.

#2 The Definition of Torque

Torque is Not Defined as Mass Times Length

The SI base units for torque are mass, time, and length. According to the SI-Brochure-9-EN (downloadable here), the definition of torque is the cross product of a position vector and a force vector.

The SI unit is newton metre. Even though torque has the same dimension as energy (SI unit joule), the joule is never used for expressing torque.

Thus, our definition of torque is force times length. It is not force times mass. In discussions with many professionals and manufacturers of torque equipment, we have found that some labs use mass weights at the end of a torque arm and claim they are applying torque.

It worsens as many manufacturers use terms like in- lbs, or ft - lb. However, we have yet to see Newton Meter (N m) written as Meter Newton (m N). Using the wrong symbol is sloppy on the part of several manufacturers.

The issue besides the wrong naming convention is that the errors from using mass weights alone can be quite large.

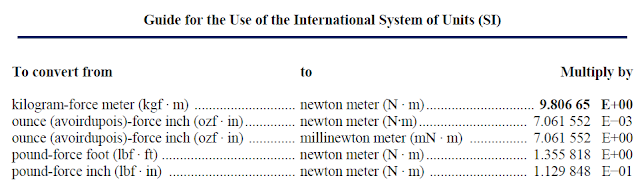

The above table shows the proper naming convention for torque and common conversions. There is no conversion to ft lbf or from ft lbf.

#3 Mass versus Force

Let us quickly review the difference between mass and force. Mass, under almost every terrestrial circumstance, is the measure of matter in an object.

However, measuring force takes additional factors into account: air density, material density, and gravity.

The effect of gravity can produce significant errors when comparing mass and force measurements.

Gravitational Variation

One of the main issues with using mass weights for torque calibration is the dependence on gravitational force. The torque produced by a mass weight is a function of its mass, the distance from the pivot point, and the gravitational force acting on the mass.

Gravitational force, however, is not constant across the Earth's surface; it varies with altitude, latitude, and local geology.

The most extreme difference is 0.53 % between the poles and the equator (983.2 cm/s2 at the former compared to 978.0 cm/s2 at the latter).

This means that the torque produced by a mass weight will also vary depending on the location of the calibration, likely leading to measurements with significant and often unaccounted-for errors.

A torque-measuring device calibrated in one location using mass weights and then deployed somewhere else will produce different physical elements, and the resulting measurement errors can be significant.

Correcting for the difference in force and mass measurements is possible. When adjusting a device for force measurements, the device will measure force without additional error for gravity correction, air density correction, etc.

Correcting for Force

To convert to force, we use a formula:

Force = M x g / 9.80665 (1 – d/ D)

Where M = mass of weight in lbs, g = gravitational constant at fixed location in m/s2, d = air density in g/cm^3, and D = material density g/cm^3

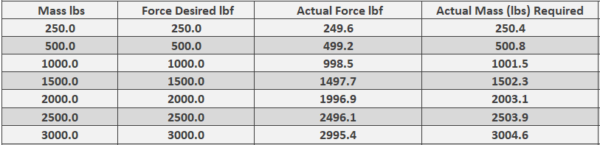

The above example shows an additional error of about 0.153 % from not correcting mass weights for the force at the location of the measurement. A desired force of 3000 lbf requires the actual mass to be 3004.6 lbs for the given gravity, air density, and material density.

Morehouse has a spreadsheet to help you do the conversions. The sheet asks the end-user to provide information about their air density and gravity and lists various material densities to get as close to the correct force as possible. The download link is provided at the end of this article.

#4 Sensitivity to Environmental Conditions

All weights are sensitive to environmental conditions such as temperature, humidity, and air pressure. Changes in these conditions can affect the mass of the weights, resulting in fluctuations in the torque they produce.

For example, the mass of a weight can increase or decrease due to thermal expansion or contraction, leading to inconsistent torque measurements.

This issue can be particularly problematic in locations where environmental conditions fluctuate significantly.

When weights are corrected for force, the environmental conditions should be controlled as tightly as possible. We typically recommend ± 1 °C. When these controls are in place, the additional error from air density is typically below 10 ppm.

According to NBS Monograph 133 at a constant temperature of 23 °C, barometric pressure and humidity changes may cause the actual air density to vary as much as 3 % in either direction from the average air density at a given time and place (about 6 ppm).

# 5 Handling and Storage Issues

Proper handling and storage of weights are crucial for maintaining their accuracy. Improper handling can cause scratches, dents, or other damage that can alter the weight, affecting the torque calibration results.

Additionally, weights can be susceptible to corrosion, leading to changes in their mass and, consequently, the torque they produce. Ensuring proper handling and storage can add to the overall complexity of the torque calibration process as these weights are often handled frequently.

Torque Calibration Conclusion

Using mass weights for torque calibration may seem like a simple and cost-effective solution; however, being aware of the limitations and errors associated with using mass weights is essential.

Use weights corrected for force to ensure accurate and reliable torque calibration. Doing so will be technically correct, improve measurement uncertainty, and reduce bias, leading to higher quality and safety.

It is essential to correct any mass weights for force or purchase weights corrected and adjusted for force by correcting for gravity at the location they are being used, air density corrections, and material density.

Morehouse has created an Excel spreadsheet that is free to download to help eliminate significant measurement errors from using mass weights.

Download Mass to Force Excel Document Here

We also make force weight sets. If you want nominal values and not have to report odd numbers, these weight sets will be adjusted for the force at the location they are being used. Please email sales@mhforce.com for more information on our custom force weight sets.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment.

We challenge the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors, and focus on reducing them. Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Please email sales@mhforce.com

For more information on Morehouse, please view our YouTube channel.

#Torque Calibration