Relative Zero Error: What You Need to Know About Load Cells with High Zero Returns

Does this sound familiar; you bought a load cell that fit your form and function needs, and everything looked good for what you wanted to accomplish on paper. You send the load cell off to be calibrated and find out the calibration looks good, though the raw data shows a high zero return.

A large zero likely needs to be reduced every time the load cell is used; these zero returns can vary on many load cells from as little as 0.0001 % to as much as 0.25 % or higher.

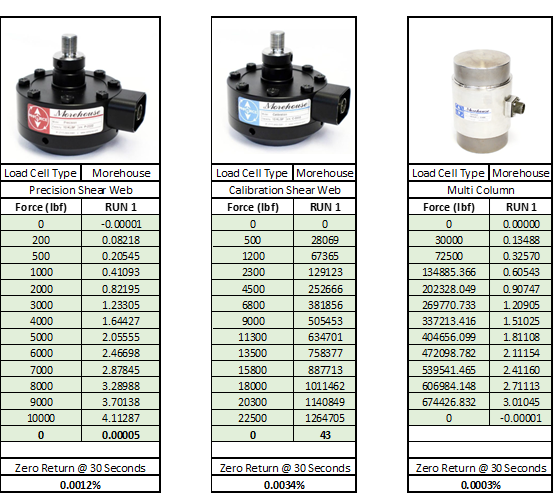

For this blog, we examined five random load cells from recent calibrations and selected two shear web loadcells, two single-column loadcells, and one multi-column load cell. We recorded the percentage of error that might be present if the ending zero is ignored versus netted out.

This topic is important because Morehouse wants anyone purchasing load cells to know how to source the appropriate load cells for their applications. Failure to do so often results in subpar performance, calibration technician frustration, and an unwillingness by management to spend additional money to correct the problem.

Of the five load cells sampled, the first two are non-Morehouse single-column load cells showing significant variation between the manufacturers. The other three load cells are from Morehouse and are not single-column load cells. The purpose is to show any variation within the load cells we would recommend to anyone wishing to meet the Relative Zero Error requirements of ISO 376.

We will show what might cause these high zero returns and provide additional information on whether these load cells would be good enough to use for ISO 376 calibrations. We're looking at ISO 376 calibrations simply because ISO 376 has a requirement for zero returns, known as the Relative Zero Error, which clearly defines how good a load cell must be.

The Load Cells

Each style of load cell typically has its own advantages and disadvantages, from the physical size to the price versus performance, and we will pull data from our e-book "Force Calibration for Technicians and Quality Managers" for some general information on the three types of load cells sampled.

Morehouse Shear Web Load Cells

Advantages

• Typically have very low creep and are not as sensitive to off-axis loading as the other load cells.

• Recommended choice for force applications from 100 lbf through 100,000 lbf.

• Will meet ISO 376 Class 00 Relative Zero Error Requirements

Disadvantages

• Over 100,000 lbf (450kN) capacity, the loadcell's weight makes it exceedingly difficult to use as a reference standard in the field. A 100,000 lbf (450 kN) capacity shear web load cell weighs approximately 57 lb (26 kg), and a 200,000 lbf (900 kN) capacity shear web load cell weigh over 120 lb (55 kg).

Single Column Load Cell

Advantages

• Physical size and weight: It is common to have a 1,000,000 lbf column cell weighing less than 100 lb (45 kg).

Disadvantages

• Single-column loadcells have a reputation for inherent Non-Linearity. This deviation from linear behavior is commonly ascribed to the change in the column's cross-sectional area (due to Poisson's ratio), which occurs with deformation under load.

• Sensitivity to off-center loading can be high.

• Larger creep characteristics than other load cells often do not return to zero, meaning high Relative Zero Error

• Different thread engagement can change the output.

• The design of this load cell requires a top adapter to be purchased with it. Varying the hardness of the top adapter will change the output.

• Typically, single-column loadcells will not meet ISO 376 Class 00 or Class 0.5.

Multi-Column Load Cells

Multi-column load cells are typically good from 100,000 lbf (450 kN) through over 1,000,000 lbf (5MN). The load is carried by four or more small columns in this design, each with its own complement of strain gauges, and the corresponding gauges from all the columns are connected in a series in the appropriate bridge arms. The Morehouse multi-column 600K load cell weighs 27 lb (12 kg) and has an accuracy of better than 0.02 % of full scale.

Advantages

• Can be more compact than single-column cells.

• Improved discrimination against the effects of off-axis load components.

• Typically have less creep and better zero returns than single-column cells.

• In many cases, a properly designed shear-web spring element can offer greater output, better linearity, lower hysteresis, and faster response.

• Will typically meet ISO 376 Class 00, but should always meet ISO 376 Class 0.5

Disadvantages

• The design of this load cell requires a top adapter to be purchased for use. Varying the hardness of the top adapter will change the output.

The Data – Comparing Two Single Column Load Cells by Different Manufacturers

Let us look at the data of two manufacturers using single-column load cells. The Relative zero error, determined by dividing the zero after 30 seconds of the forces being removed, is more than three times higher on the one Single Column load cell.

The error is found by taking the residual force readings after 30 seconds of the forces being removed, dividing that by the full-scale output, and then converting it to a percentage by multiplying it by 100.

Suppose the end-user uses the load cell to calibrate universal tensile testing machines. In that case, they are likely claiming around 0.25 % or better for their measurement uncertainties. Still, as we can see, the Relative Zero Error adds well over 10 % of that overall specification on the Example 1 load cell if they ignore the end zero, and the calibration laboratory reduces it. In that case, the maximum value of 1402542 will become 1402184, a difference of 358 or 0.0255 %, which add about another 10 % to the measurement uncertainty, as stated above.

More on this later, but for now, the question is, why are the performance characteristics relating to Relative Zero Error so different? Morehouse’s lead R & D and load cell design engineer explains that a lot could impact any load cell's performance. For example:

One difference could be that manufacturer A overloaded the load cell by 150 %, which helps condition the material and reduce the amount of Relative Zero Error.

A word of caution here - be careful if you own one of these load cells and think overloading to 150 % might make it better. If the manufacturer knocks down the output from, say 3 mV/V to 2 mV/V, putting an overload of 150 % can lead to damage to the gauges from the high stress.

Another possibility would be that manufacturer B uses strain gauges better matched to the material and/or could have a better method for applying the strain gauges. If you want a better zero return, matching the appropriate gauges with the material is imperative.

Yet another possibility might be that manufacturer C might be using a Vacuum melt material that provides better stability, repeatability, and low-temperature performance.

Whichever explanation is relevant to the manufacturer, we don’t believe anyone would think there isn’t a significant difference between the Relative Zero Error of these two load cells.

The Data – Comparing Three Morehouse Load Cells

You might be asking yourself why we didn’t use any of Morehouse’s single-column load cells in the comparison... the straightforward and honest answer is that we believe our Shear Web and Multi Column load cells are so superior that we urge anyone wanting a load cell to consider shear webs or multi-column load cells over single column loadcells. The data below backs up our claim and proves our point.

Not only do these load cells perform better by handling a variety of loading conditions, but they also have phenomenal Relative Zero Errors, minimizing the extra uncertainty in reducing the ending zero.

All three Morehouse load cells have Relative Zero Errors below 40 parts per million or 0.004 %. Some of it becomes noise when the zeroes are less than ± 0.00005 mV/V. For instance, the calibration shear web is used on a meter with a bit more fluctuation, likely about 0.002 % more than when used with our 4215 Plus or 4215 HS indicator.

Additional Notes on Relative Zero Error

The two common standards for calibrating Elastic Force Measuring Equipment are ASTM E74 and ISO 376, and each has its requirements for the relative zero error.

ASTM E74

Allows two methods to handle the end zero reduction. One method, known as Method A, allows for the ending zero to be ignored. If this method is selected, a creep test must be performed. The second method, Method B, allows for the ending zero to be determined by an average or interpolation; specifically, the treatment of zero in determining deflections is stated in section 8.1 of the ASTM E74 standard.

Section 8.2 Determination of Creep Recovery states, "Creep affects the deflection calculation. Excessive creep is indicated if a large non-return to zero is observed following force application during calibration. A creep recovery test is required to ensure that the creep characteristic of the device does not have a significant effect on calculated deflections when method (a) is used to determine deflections."

The standard shows you how to perform the Creep Recovery tests and that the error limits must be less than 0.05 % for a Class A device.

"Zero Return Error, % of Output at Applied Force = 100 × (Initial zero reading – Final zero reading 5 minutes after the applied force is removed) /Output at Applied Force. The creep test shall be repeated if the zero return error exceeds 50% of the creep recovery error limits."

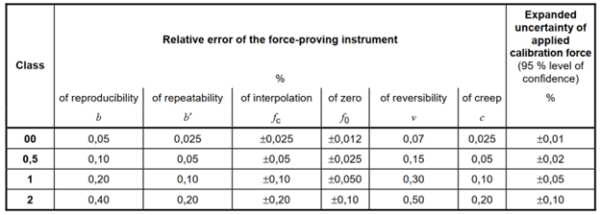

ISO 376

ISO 376 is slightly different than ASTM E74 as there is no escaping a load cell with bad relative zero error. The standard provides a table of what is required for each classification of the load cell. If any difference between the beginning and ending zero exceeds 0.012 %, the load cell cannot be classified as Class 00.

In our below example, the one load cell had a Relative Zero Error of 0.0255 %, which would mean class 1 would be the best classification of the load cell, assuming all the other criteria were met.

What You Need to Know About Load Cells with High Zero Returns (Relative Zero Error) - Conclusion

Our knowledgeable team at Morehouse continues to work with everyone, clarifying complex topics and providing tools such as free guidance documents, Excel™ sheets, and products to help you make better force measurements. Our mission is to ensure quality personnel have the resources to make the right decisions about the load cell they purchase. We have been in business for over a century and focus on being the most recognized name in the force calibration business.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do and provide is designed to change how people think about force and torque calibration. We challenge the "just calibrate it", or, even worse, “just sticker it” mentality by educating our customers on what’s important and why it matters, what causes significant errors, and how to focus on reducing them. In addition, Morehouse makes simple-to-use force calibration products, building excellent force equipment with the key tenets of plumb, level, square, rigid, and torsion-free frames.

If you have more questions about Relative Zero Errors, other force measurement specifications, calibration, need adapters, load cells, or other questions, don't hesitate to get in touch with us @ 717-843-0081 to talk to a live person or email info@mhforce.com . Visit us on the web at mhforce.com.

#Relative Zero Error