Understanding Risk: Making Better Measurement Decisions

Understanding Risk Intro:

Why Measurements Aren’t Always Exact

Every measurement we take comes with some level of doubt. This doubt is called measurement uncertainty. It’s the range within which the “true value” probably lies.

When understanding risk, think of it like reading a ruler: if your eyes are a little off, you might be within a millimeter (or half of one if you still have great vision) too high or too low. That small doubt is uncertainty.

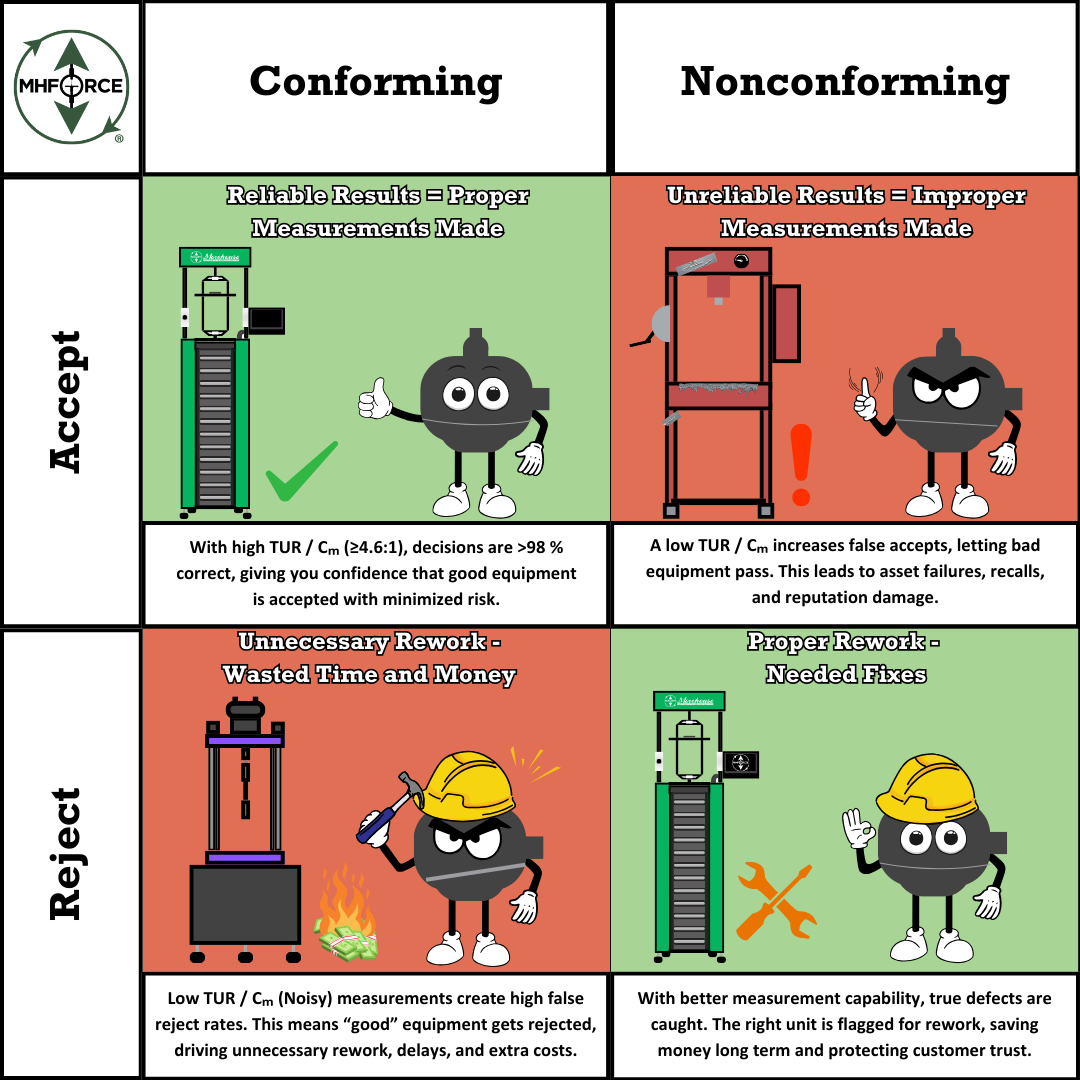

Two Kinds of Mistakes We Want to Avoid

When we make decisions from measurements, there are two main mistakes we want to avoid when understanding risk:

- False Accept (PFA): Passing something bad.

- Example: A cracked bridge cable gets marked as safe because the test wasn’t accurate.

- In the chart: This is the Nonconforming + Accept box (top right, red). The test says “good,” but the item is really bad. This mistake can cause dangerous failures, recalls, and harm trust.

- False Reject (PFR): Failing something good.

- Example: Perfectly fine medicine bottles get thrown away because the measurement said they were off.

- In the chart: This is the Conforming + Reject box (bottom left, red). The test says “bad,” but the item is really fine. This mistake wastes time and money on rework that isn’t needed.

Both PFA and PFR situations cost money, waste time, or even put people in danger. PFA risks safety and liability. PFR wastes resources and damages reputation.

Decision Rules: Setting Clear Boundaries

A decision rule is just a clear guideline for how to decide “pass” or “fail” while taking uncertainty into account. It helps us with understanding risk. Instead of saying, “Close enough,” the rule defines acceptable risk.

For example, a company might say:

- “We will accept a part only if the chance of a false accept (PFA) is less than 5 %.”

This makes the risk level clear for everyone: customers, regulators, and technicians.

While we discuss measurement decision risk (MDR), there are typically two different types of risk analysis.

- Specific Risk (bench-level) → risk tied to a single measurement result (false accept/reject at time of test).

- Global Risk (process-level) → risk evaluated over time/historical data (e.g., calibration process capability, end-of-period reliability).

Guardbands: Adding a Safety Buffer

One way to manage risk is by using a guardband. A guardband shifts the pass/fail limits inward by a small margin, so only items well within tolerance pass. This lowers the chance of passing a bad item (lower PFA), but it also increases the chance of rejecting good items (higher PFR).

The key is balance: too strict, and you waste good products; too loose, and you risk safety.

Why Balance Matters

Sometimes, when the measurement is right on the edge of the allowed tolerance, the chance of a mistake can be 50/50. That means half the time you’ll reject a good part, and half the time you’ll accept a bad one. This is the worst-case scenario, and it’s why decision rules are needed.

This exact situation is called “shared risk,” and it means no guardband has been applied, and you, as the victim customer of said equipment, may absorb 50 % of the risk.

The Big Picture: Risk vs. Cost

When choosing a calibration standard, it’s tempting to focus only on the sticker price. But just like buying a car, the real question is not “What does it cost today?” but “What will it cost me over the next 5, 10, or 20 years?”

Risk and cost are connected. Every time you calibrate with a standard, you’re making a decision: is the customer’s equipment “good” or “bad”? If your standard has high uncertainty, your risk of making the wrong decision goes up. That wrong decision has a price—sometimes small, sometimes huge.

- False Accept (PFA): You say something is “good” when it’s actually out of tolerance. This can lead to safety problems, bad products, recalls, or even accidents. The cost could be millions of dollars—or even lives.

- False Reject (PFR): You say something is “bad” when it’s actually fine. This doesn’t risk safety, but it wastes time and money. You redo work, lose time, or frustrate customers.

Simply Stated:

- Higher false accept rates risk safety, recalls, and liability.

- Higher false reject rates waste resources but don’t usually endanger safety.

Now think about this:

- At low TUR (like 1:1), you might reject 1 out of every 3 “good” items by mistake. That’s hours of wasted work, year after year.

- At higher TUR (like 4.6:1 or more), both false rejects and false accepts drop much closer to zero. That means less wasted effort and much lower risk of a costly mistake.

So, while a high-precision deadweight standard may cost more upfront, it protects you from those hidden costs. Over years of operation, the savings in reduced rework and avoided mistakes can easily outweigh the purchase price.

Why Does It Matter to You

Every “false reject” wastes your team’s time. Every “false accept” risks your customers’ trust. Both cost money in the long run.

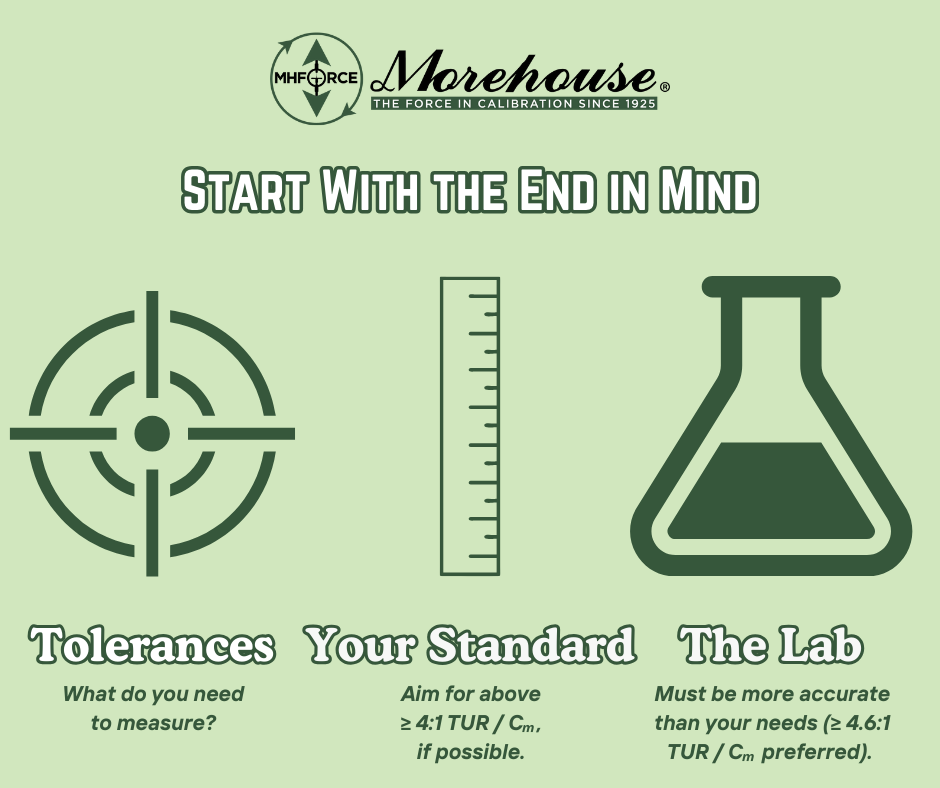

Start With the End in Mind

Before choosing a calibration standard, it helps to visualize the end goal. Ask yourself three questions:

1. Tolerances — What do you need to measure?

If your customers expect tight tolerances, your calibration work must have a lower measurement uncertainty than what you want to calibrate. For example, if you need to calibrate to 0.1 %, your standard must be much better than 0.1 % otherwise, you’re guessing instead of proving. (Note: there are exceptions to this when there is no better standard available).

2. How much better should my standard be?

A common rule of thumb is to aim for at least a 4:1 Test Uncertainty Ratio (TUR). That means your standard should be at least four times more accurate than the device you’re testing. At this level, the risk of a bad decision (false accept or false reject) is very small. Ideally, your standard is at least 4.6 times better, though 2 can work, as can 1.5:1.

3. How good does the lab need to be?

Even if you buy the best measurement standard, it still needs to be calibrated. It is key when understanding risk to know that the accuracy of that calibration depends on the lab you choose.

If the lab’s measurement uncertainty is higher (worse) than your needs, it will cancel out the advantage of owning a high-quality standard.

For example:

- If your work requires > 0.025 % accuracy, the calibration lab must be much more accurate than that.

- Otherwise, their higher uncertainty gets “added” to yours, and your results cannot be better than the lab’s limits.

Simple Rule of thumb: You can’t have lower uncertainty than the lab that calibrates your standard. This is explicitly required for metrological traceability under ISO/IEC 17025.

By starting with the end in mind—your tolerance needs, your standard’s performance, and your lab’s capability—you can avoid buying equipment that looks good on paper but won’t deliver in practice. This approach protects your investment and ensures every calibration decision is backed by real confidence.

The Bottom Line

It’s less about the upfront price tag and more about the total cost of ownership.

Every hour you spend waiting for equipment, redoing work, or sorting out quality issues is time you’re not making money, and potentially harming your reputation.

Every wrong decision can result in unnecessary costs, extra analysis, and even potential recalls, all due to a “bad” decision from using equipment or suppliers with high measurement uncertainties.

Choosing the right force machine means looking beyond sticker price to the full picture: downtime, maintenance, uncertainty, and rework. The real value lies in performance, reliability, and the confidence that every calibration decision you make is the right one.

Simply put, A lower TUR can help Stop Rework and allow you to Start Saving more time and money.

Closing Takeaway for Understanding Risk

- Choosing equipment and labs isn’t just cost — it’s about protecting against hidden long-term risk.

- Aim for at least a 4.6:1 TUR, when possible.

- Choose a calibration lab at least 4 times better than your needs, if possible.

- Always state the decision rule used when reporting conformity.

Reference Standards:

- ISO/IEC 17025:2017 – requires laboratories to clearly define and communicate decision rules when making conformity statements.

- JCGM 106:2012 – explains how uncertainty affects conformity assessment and the probability of false accept/reject.

- ILAC G8:2019 – provides practical guidance on applying decision rules and guardbands.

More Information about Morehouse

We believe in changing how people think about Force and Torque calibration in everything we do, including discussions on force calibration procedures

This includes setting expectations and challenging the "just calibrate it" mentality by educating our customers on what matters and what may cause significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition, providing you with more accuracy and precision in force measurement.

We turn around your equipment in 7-10 business days so you can return to work quickly and save money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Through Great People, Great Leaders, and Great Equipment, we empower organizations to make Better Measurements that enhance quality, reduce risk, and drive innovation.

With over a century of experience, we're committed to raising industry standards, fostering collaboration, helping with understanding risk, and delivering exceptional calibration solutions that build a safer, more accurate future.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff. We have many more topics other than understanding risk.

Our YouTube channel has videos on various force and torque calibration topics here.

#Understanding Risk