Problem Statement: Technical Life Care needed a better, more precise, way to calibrate Hand-Held Dynamometers. These devices are used to determine a patient's muscle strength and knowing the proper measurement allows doctors to quickly diagnose ICU survivors' physical function and determine the proper treatment. A wrong measurement could potentially lead to a misdiagnosis.

Problem Statement: Technical Life Care needed a better, more precise, way to calibrate Hand-Held Dynamometers. These devices are used to determine a patient's muscle strength and knowing the proper measurement allows doctors to quickly diagnose ICU survivors' physical function and determine the proper treatment. A wrong measurement could potentially lead to a misdiagnosis.

Morehouse was contacted to develop a fixture for their Hand-Held Dynamometers to add to the Portable Calibrating Machine (PCM). Their previous technique was insufficient, inefficient and unsafe, requiring two people to lift and hold a pipe, or rod, horizontally, hang a hand-held dynamometer on it and begin to stack weights on the free end of the dynamometer. Stacking weights can create serious issues: when weights are stacked, they may fall and need to be aligned and calibrated once more, or worse still, they could fall on one of the techs and cause injury.

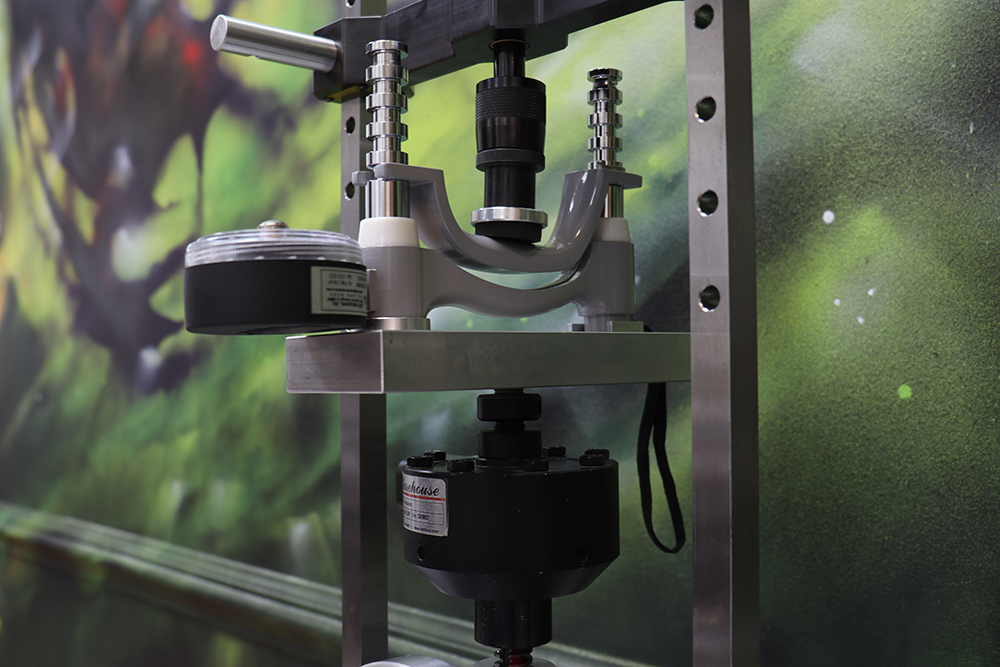

The Portable Calibrating Machine (PCM) saves the company time by only requiring one technician and is a safer method compared to the alternative method of stacking weights. The Portable Calibrating Machine (PCM) is a force calibration machine designed to measure smaller instruments under 2000 lbf capacity and is paired with a reference load cell and Morehouse indicators.

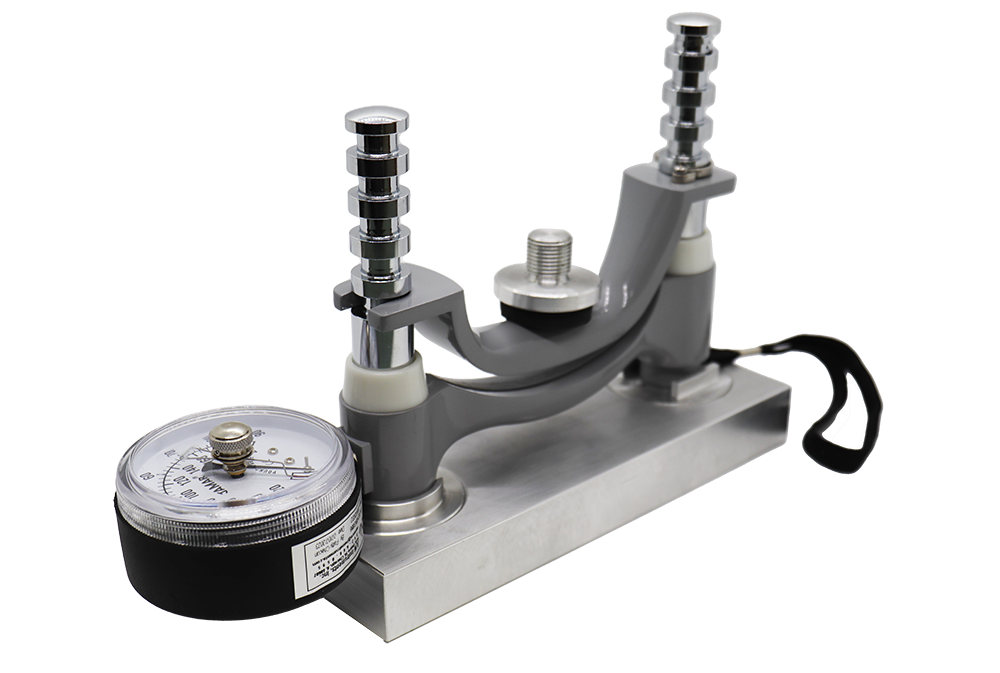

Hand-Held Dynamometer Adapter

Our PCM applies load and allows load cells to measure that applied force, reporting the values on the Morehouse indicator. No supplier has had any fixture to add Technical Life Care’s hand-held dynamometers to a Portable Calibrating Machine (PCM) until the Morehouse team created a fixture using appropriate materials that fit within the machine parameters and lock the hand-held dynamometer instruments into place.

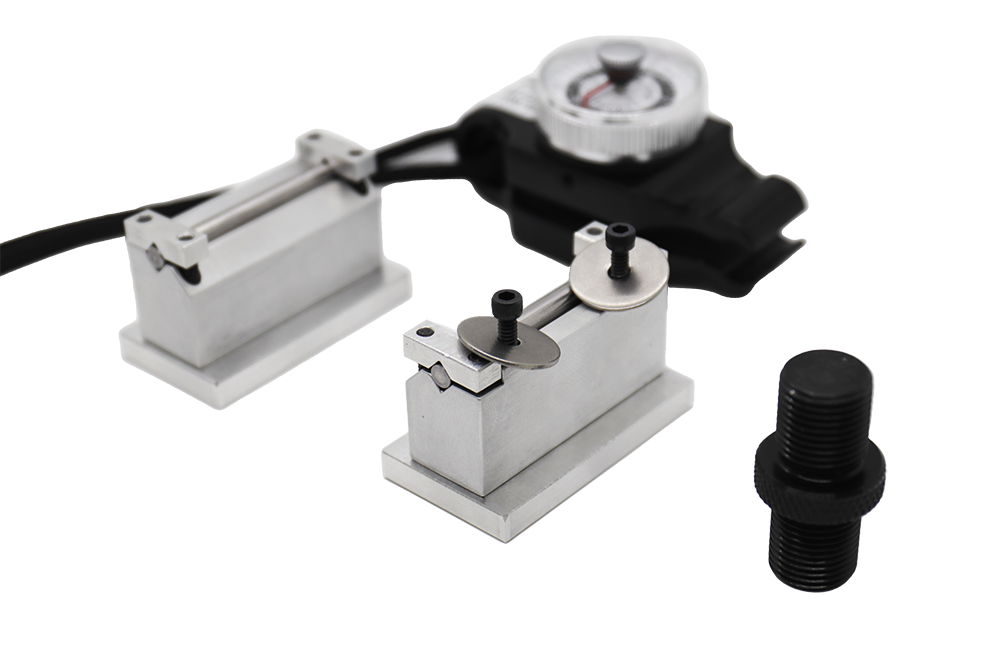

Pinch Gauge Dynamometer Adapter

Morehouse has also developed an adapter that will fit mechanical pinch gauges. Pinch gauges can be calibrated from 0.25 lbf up to 60 lbf, and since these devices need to be calibrated precisely, the PCM is the perfect machine to use with this new adapter. When using our reference load cell and Morehouse indicators with this adapter, we can guarantee a force application as low as 0.005 lbf based on the resolution of the reference standard used.

Technical Life Care selected Morehouse as their supplier of choice because of our reputation, experience, and profound understanding of force measurement. We are leading the industry with our knowledge and expertise, providing our customers with better force measurement solutions. We make sure our customers have the best quality adapters, calibration machines, and loadcells for their industrial force measurement requirements.

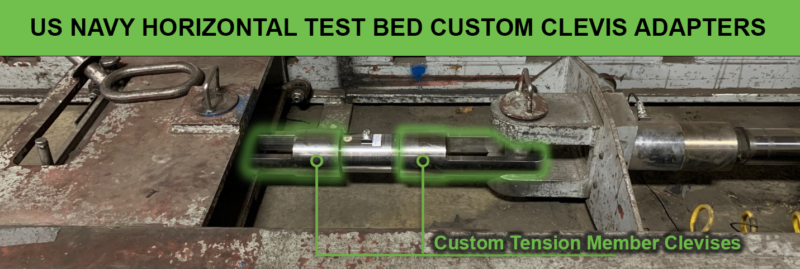

The Navy had a big task for Morehouse. The Navy needed their Horizontal Test Bed calibrated. The Navy reached out to Morehouse to help come up with an accurate way to calibrate their Horizontal Test Bed. This machine produces 1.2 million pounds of force. The Morehouse team applied force measurement fundamentals to their problems and came up with appropriate fixturing through the creation of custom clevises. Clevises help to correctly connect and align devices, allowing superior tensile force calibrations of dynamometers, load links, tension rods, crane scales, and other weighing devices. These clevis sets were created by using the individual parts of the testing bed and breaking down the process into stages.

The custom clevis set was engineered to correctly adapt the load cells to the pulling pins of the Horizontal Test Bed. The attachment ensures that when the machine applies tensile forces, the force will be measured correctly.

Using only photographs and measurements provided by the Navy, the Morehouse team engineered a custom solution to adapt calibration load cells to the Navy's Horizontal Test Bed. Creating the custom clevis set was difficult because the only available information given was images and measurements. Still, the experience of the Morehouse team worked through it to create a solution. The Navy chose Morehouse due to decades of conducting business with Morehouse.

Morehouse sells its custom clevis assembly for tension adapters to calibrate weighing devices. The assemblies can be used with Morehouse Quick Change Tension Members to minimize errors by improving tension alignment.

We helped the NASA International Space Station find a non-load cell solution in a nickel-coated proving ring to help Astronauts set the appropriate exercise forces. Throughout the world in industry and standards laboratories, the Morehouse Proving Ring is recognized for its lasting reputation of unquestionable accuracy in measuring mechanical forces.

We helped the NASA International Space Station find a non-load cell solution in a nickel-coated proving ring to help Astronauts set the appropriate exercise forces. Throughout the world in industry and standards laboratories, the Morehouse Proving Ring is recognized for its lasting reputation of unquestionable accuracy in measuring mechanical forces.

The Morehouse Proving Ring is an invaluable tool for measuring forces in industrial strength testing. We provided a custom solution to NASA stating a nickel-coated proving ring capable of handling up to 5000 lbs of force, perfect for any environment, even outer space.

NASA partnered with us to create the ultimate exercise machine. Its purpose sends a clear message: keep our astronauts in peak physical condition even while on missions.

Our proving ring is the most accurate and durable in the world. With decades of experience and calibration, we can help your testing machine, torque-measuring dynamometer, thrust standard, electronic and hydraulic load cells, and many other force-measuring devices and systems.

Problem Statement: One of our nuclear customers needed a 2.25 million lbf load cell calibrated. The Nuclear Customer does power plant in-service inspections and post-tensioning inspections. This cell is essential for their operations, so a precise and time efficient calibration was required. The main issue is that the load cell’s weight and size make it a difficult calibration for most laboratories.

Morehouse had calibrated this instrument once before and was contacted to calibrate the cell once again. At Morehouse, the calibration was conducted in our 10 MN Morehouse UCM. The calibration of which is traceable to SI units, with calibration performed directly by NIST. Morehouse used three load cells calibrated to 800,000 lbf to achieve a force of 2,250,000 lbf with measurement uncertainties of better than 0.01 %.

The Calibration Process: The load cell was sent to Morehouse in a crate and the adapters were sent on a skid. A forklift was utilized to hoist the cell and adapters into the Morehouse UCM. Once the adapters and cell were properly placed into the machine, Morehouse technicians ran through tests and prepared for calibration. The entire process took 10 business days.