Metrology AI

There have been a lot of questions and discussions about using AI to analyze data for use in Metrology.

This post about metrology AI will show some of the powerful tools and how to use them in ChatGPT 4o, which became available on September 12, 2024, and discuss some of the statistics being used.

Metrology AI example:

Figure 1 NIST Report for S/N 70751

Figure 1 NIST Report for S/N 70751

After logging into the PRO (Paid) version of ChatGPT, the first step is to load PDF reports.

In this Metrology AI use example, we will use our 1,000,000 lbf Reference Load Cell Standard S/N 70751, which was calibrated directly by NIST.

We drag and drop the pdf files into the ChatGpt message prompt.

Figure 2 Dropping Data into ChatGPT

From here, we can ask all sorts of questions and have ChatGPT sort the data into a more presentable format.

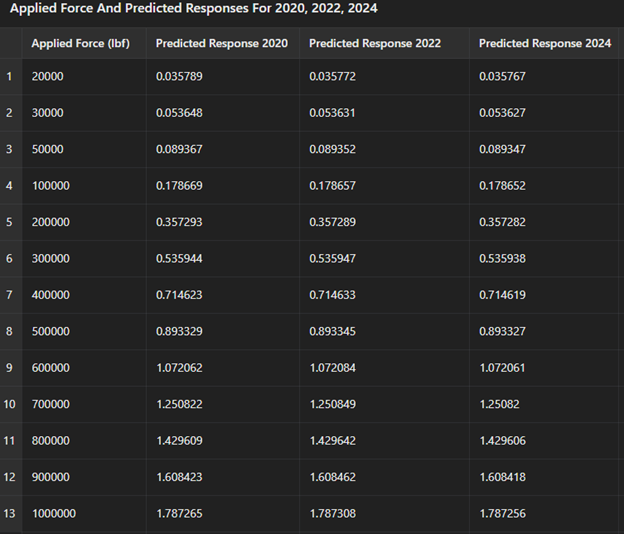

Maybe we want to see a table of the applied force versus each year’s predicted response.

In this case, we could type. Use the .pdf files and make a table of force applied in lbf, using the predicted response from each year.

Figure 3 Formatted Data from Three PDF Files

The data is now presented, and we can export it into Excel if we want, or we can ask ChatGPT to graph the data.

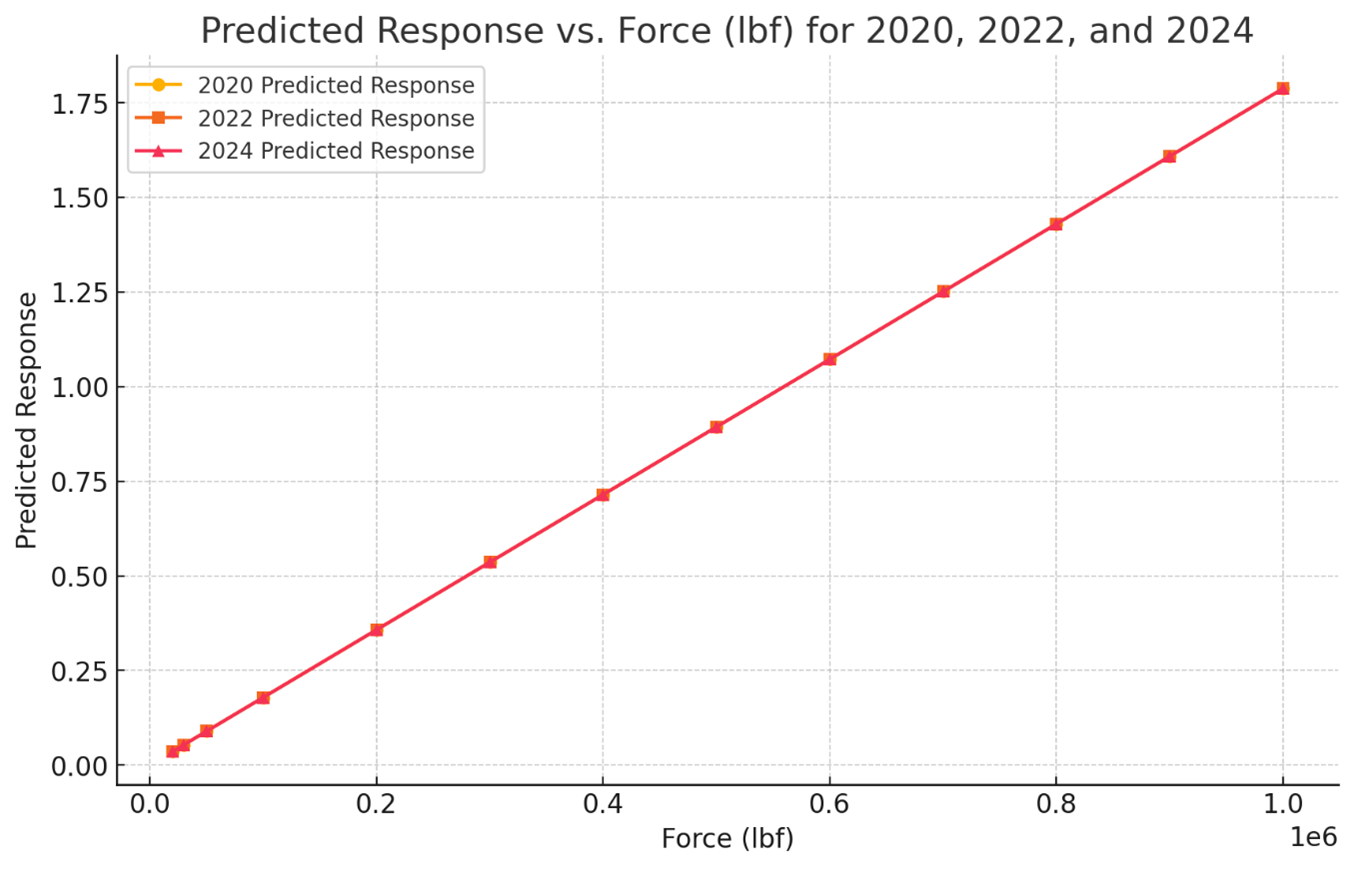

Figure 4 A Graph of the Data Plots

Figure 4 A Graph of the Data Plots

Though most of this is simple and can be a time saver when exporting from a PDF into Excel or another document,

What is very cool is the ability to predict future results and run a more comprehensive statistical analysis, which leads us to what I consider very useful Metrology AI.

Let’s type something like “Perform a complete statistical analysis of all three pdf files.”

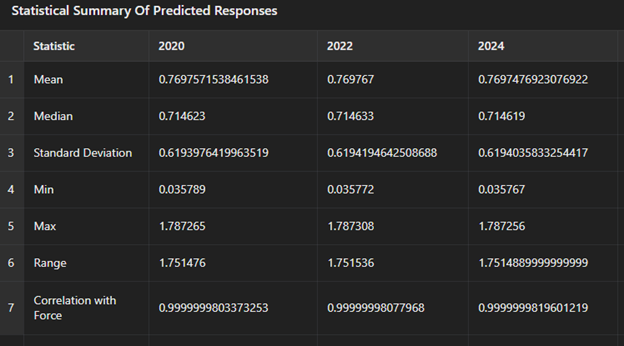

- Descriptive Statistics: Mean, median, and standard deviation of the predicted responses for each year. Variance and range of predicted responses across the datasets. By analyzing the predicted responses' mean, median, and standard deviation, you can understand the central tendency and spread of the data. For example, the mean predicted response is similar across the years, indicating consistency in the measurements.

- Trend Analysis: Comparison of the predicted responses across the years to see if there is a consistent trend (e.g., increasing or decreasing response).

- Correlation: Correlation between force and predicted response for each year. The correlation coefficient (near 1.0) suggests a strong linear relationship between the applied force and the predicted response. This means that as force increases, the predicted response increases almost perfectly proportionally.

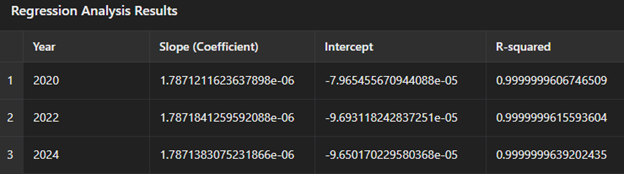

- Regression Analysis: Fitting a regression model for each year’s data to understand the relationship between force and predicted response. The regression analysis allows you to quantify the relationship between the applied force and the predicted response. The slope (coefficient) tells you how much the predicted response changes per unit of force. The R-squared value being 1.0 suggests a perfect fit, meaning the regression model explains 100 % of the variability in the predicted response based on force.

Figure 5 Descriptive Statistics

Figure 6 Regression Analysis Results

Some of this information might be very helpful.

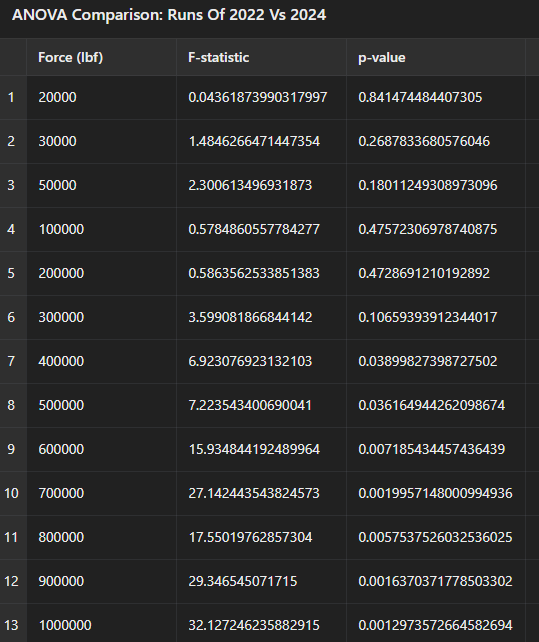

How about something a little more helpful, like using ANOVA?

“Use ANOVA to compare the runs of 2022 against 2024.”

Figure 7 Using ANOVA to Compare the Current Calibration with the Previous One

The ANOVA comparison of the runs between 2022 and 2024 for each force point reveals that:

For all force points analyzed (20,000 lbf to 300,000 lbf), the p-values are greater than 0.05, indicating no statistically significant differences between the runs of 2022 and 2024.

This suggests that the predicted responses for the runs in 2022 and 2024 are similar across these force points.

ANOVA shows us a statistically significant difference above 300,000 lbf.

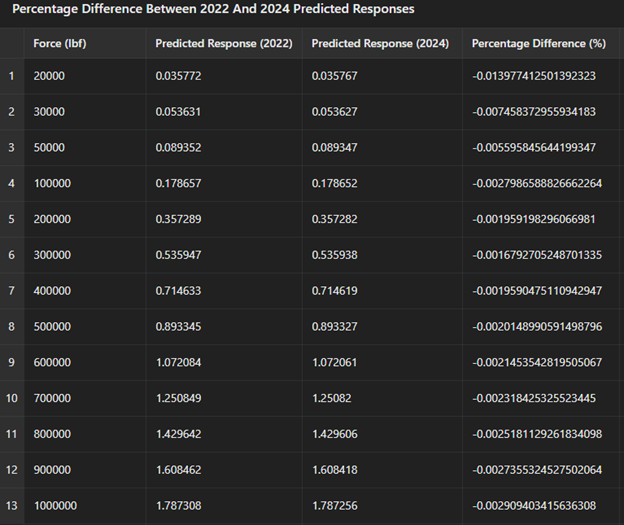

Let’s look at the actual percentage differences.

Figure 8 Percentage Difference Between the Two Calibrations

“Show me the percentage difference between the predicted response between 2022 and 2024.”

The table shows the percentage difference between the predicted responses for 2022 and 2024 across various force points. As you can see, the differences are pretty small, with all percentage differences being negative, indicating that the 2024 predicted responses are slightly lower than those from 2022. The differences range from -0.0019 % to -0.0139 %.

However, what about using this AI to do more, say, maybe predict the future behavior of our load cell?

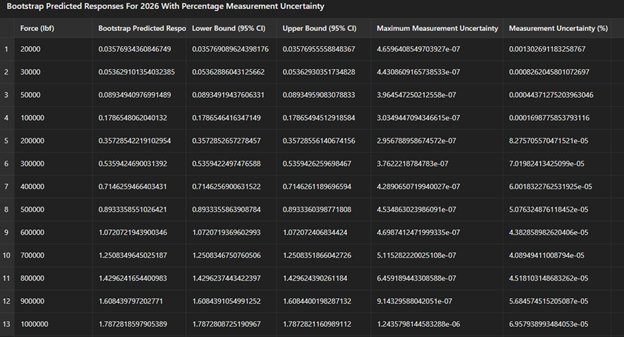

Let’s try it by typing, “Use a Bootstrapping technique to predict the predicted response values for 2026 at each force point with a confidence interval of 95 % with measurement uncertainty.”

What is Bootstrapping: bootstrapping? Let's say you want to predict a system's response in 2026 based on 2020, 2022, and 2024 data. Instead of assuming a specific distribution for future data, bootstrapping allows you to create many simulated datasets from the observed data. You can then calculate predictions for 2026 from each simulated dataset, producing a distribution of predicted responses.

To predict the 2026 response values using a bootstrapping technique and generate 95 % confidence intervals, we will follow these steps:

- Bootstrap Sampling: Generate multiple resampled datasets from the original data (2022 and 2024 responses).

- Model Fitting: Fit a regression model to each bootstrap sample and predict the 2026 values.

- Generate Predictions: Collect the predicted responses for each force point across all bootstrap samples.

- Confidence Interval Calculation: Calculate the 95 % confidence intervals by finding the 2.5th and 97.5th percentiles of the predicted values for each force point.

Figure 9 2026 Predicted Response with 95 % Confidence Interval

The table shows the predicted response values for 2026 at each force point using the bootstrapping technique and the 95 % confidence intervals. The lower and upper bounds of the confidence intervals indicate the range within which the true predicted response values are likely to lie based on the bootstrap samples. Measurement uncertainty is standard measurement uncertainty and needs to be multiplied by a coverage factor.

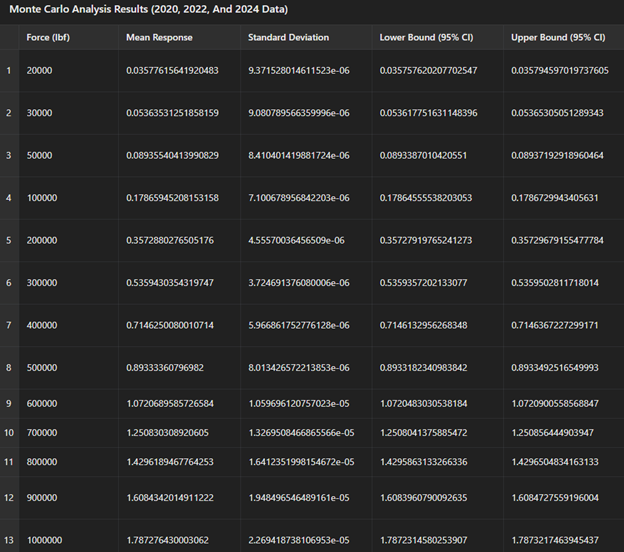

If you want to run a Monte Carlo Analysis, ask it to do it.

Figure 10 Monte Carlo Simulation

We can do so much more with the data, almost anything you can think of.

Maybe we want to run an F-test to see if the variances are similar.

Metrology AI Conclusion

Metrology AI plays a pivotal role in transforming the field of precision measurements by integrating advanced data analytics, automation, and machine learning techniques.

When it works.

You always need to double-check what you are asking and what answers it is giving.

Based on the analysis conducted using Monte Carlo simulations, F-tests, bootstrapping techniques, and statistical comparisons of predicted responses across different years, Metrology AI can offer several key benefits:

- Enhanced Measurement Accuracy and Reliability:

- Predictive Analysis: By leveraging historical data from different years (e.g., 2020, 2022, 2024), Metrology AI can predict future measurements with high precision and confidence. This improves the reliability of measurements across varying force points.

- Uncertainty Estimation: Using techniques like bootstrapping and Monte Carlo simulations, AI can accurately estimate measurement uncertainty, ensuring that critical tolerance levels are met.

- Automated Data Analysis:

- Real-time Data Processing: AI can handle vast amounts of metrology data in real-time, providing insights such as standard deviation, confidence intervals, and potential sources of errors, all in an automated fashion.

- Quick Decision Making: With automated F-tests and variance analysis, AI can detect discrepancies between datasets (such as from different years or equipment) and quickly determine if the system is stable or needs calibration.

- Optimization of Calibration Cycles:

- System Stability Monitoring: AI can analyze the stability of force measurement systems over time, ensuring that systems are operating within acceptable variances. This allows organizations to optimize calibration intervals based on actual system performance.

- Drift Detection: AI can detect subtle trends or drifts in measurements that might not be visible with traditional methods, allowing proactive calibration and minimizing downtime.

- Reduction in Human Error:

- Automated Reporting: AI can generate automated calibration reports, complete with statistical analysis, uncertainty estimation, and recommendations for improving measurement accuracy.

- Consistency: Through advanced statistical methods, AI ensures consistent measurement practices across different environments, reducing the influence of human error in complex measurement processes.

- Cost and Time Efficiency:

- Faster Calibration Cycles: AI-driven systems can reduce the time required for calibration by optimizing sampling intervals, analyzing system stability, and detecting anomalies in real-time.

- Reduced Costs: By optimizing metrology processes and minimizing unnecessary recalibrations, AI can help organizations cut down on operational costs while maintaining precision.

Metrology AI represents a significant advancement in precision measurement, improving accuracy, reliability, and efficiency. By automating complex data analysis, optimizing calibration cycles, and reducing uncertainty, AI enables organizations to achieve higher levels of precision while minimizing costs and manual intervention. The integration of AI in metrology will continue to drive the industry towards more intelligent, automated, and accurate measurement practices.

More Information about Morehouse

We believe in changing how people think about force and torque calibration in everything we do.

This includes setting expectations and challenging the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors.

It also means that we are always looking for ways to help, such as writing an article on Metrology AI to spread awareness of these awesome tools.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition.

We turn around your equipment in 7-10 business days so you can return to work quickly and save money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff.

Our YouTube channel has videos on various force and torque calibration topics here.

#Metrology AI