Budget Load Cell Tests: Load Cell Shoulder Loading Errors

Morehouse has previously addressed load cell shoulder loading errors and thread engagement in videos and articles. Here, we investigate the results of a simple design change we incorporated into our BLC series. Specifically, what occurs if an adapter is removed and the load is applied directly to the shoulder on a load cell designed with more material in the hub, as demonstrated below?

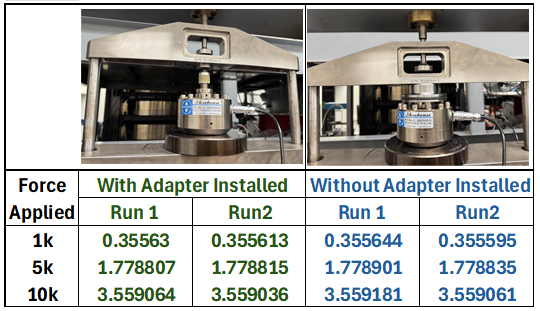

Figure 1 A Morehouse Budget Load Cell Without the Threaded Adapter Installed

Above is a load cell without the threaded adapter installed. This load cell has an adapter installed that is easily removed. The main issue when discussing load cell shoulder loading errors is that not all load cells act the same way. If one load cell has less variation than another, it might be because the design focuses explicitly on certain specifications, and maybe other aspects are neglected.

Figure 2 A Data Set Comparing the Output at Various Capacities

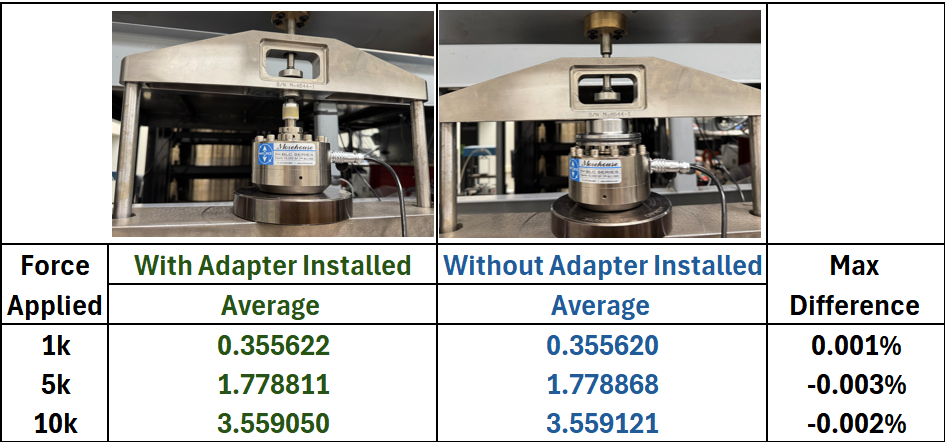

Figure 3 Load Cell Shoulder Errors Data Comparing the Averages in Output

Looking at this data, one may think that the load cell shoulder loading errors with this load cell are insignificant. One might even look at this example and think that any load cell can be loaded in any way, and the output would stay the same.

Note: This is not the case! Do not make these assumptions, as many load cells will have different outputs when loaded in different configurations.

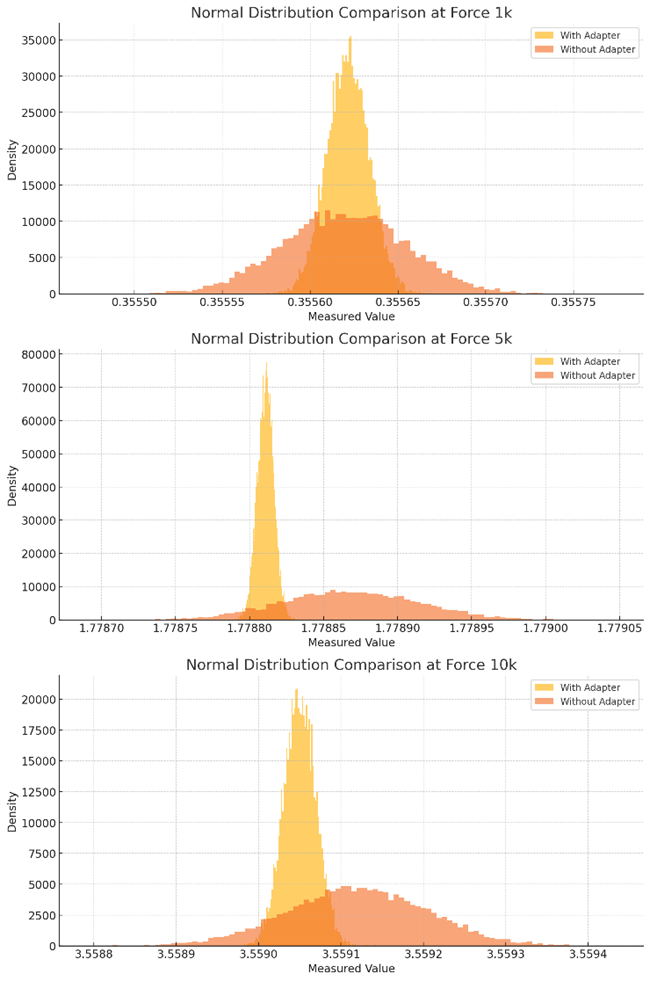

If we were to run thousands of samples, we might determine that the normal curves would be much smaller when the adapter is installed.

Figure 4 Monte Carlo Analysis of Load Cell Shoulder Loading Errors

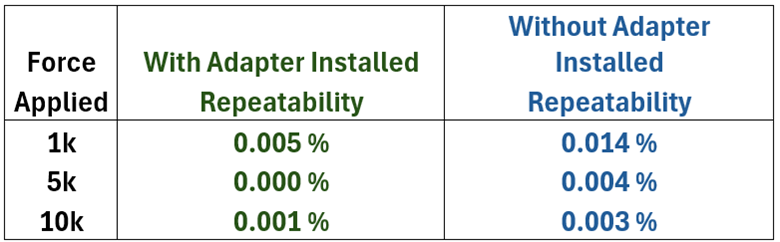

When we analyze the data, the repeatability is slightly better when the load cell is loaded with the threaded adapter installed. The Monte Carlo analysis makes it look like the variation is night and day. However, when the expanded measurement uncertainty of the Morehouse Deadweight machine is 0.002 %, the noticeable differences may not be that significant. It likely depends on what standard you are working to and how good you need your measurement to be. The difference is likely negligible if you are measuring a 1 % device.

Figure 5 Repeatability Number of Load Cell Shoulder Loading Errors on a Budget Load Cell

However, if you are working to ISO 376 or ASTM E74, the classification of the load cell or the Class A verified range of forces may vary significantly depending on the calibration method used. Therefore, it is essential to calibrate the load cell under conditions that closely resemble its intended operational use.

If you adhere to either of these standards, the differences arising from varying calibration conditions are likely substantial enough to affect the overall system classification. Consequently, end-users should carefully evaluate their intended field applications and request that the calibration laboratory replicate those conditions as closely as possible.

Alternatively, the calibration laboratory should explicitly document the loading conditions used during calibration. If this is the case, end-users must account for any discrepancies by incorporating the additional errors into their measurement uncertainty budgets.

Load Cell Shoulder Loading Errors: Thread Loading Errors

Why is thread engagement critical? When designing components with female threads, engineers often rely on standard assumptions regarding engagement length. A common guideline is to ensure that thread engagement at least matches the thread diameter. Typically, the initial threads provide the majority of strength, while engagement beyond this point usually delivers diminishing returns.

Figure 6 Thread Loading Errors - Thread Depth Errors

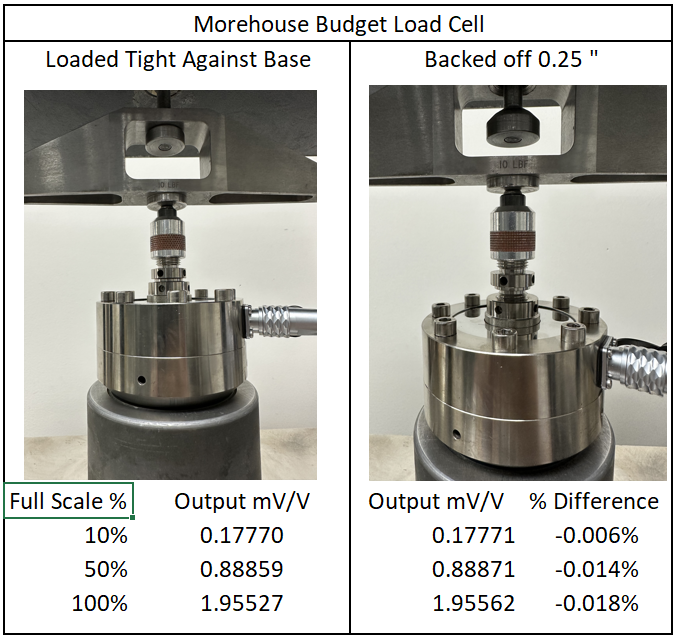

In the figure above, we record mV/V values, compare the difference with the adapter threaded tight, use the same load cell adapter, and back it off 0.25 inches.

The difference between these two readings approached a difference of about 0.02 %.

On a regular shear web-type load cell, the difference was around 10 times worse. Does that mean the Morehouse budget load cell is better? No. They are better for many practical applications because the design has more strength in the hub. It is less susceptible to the errors associated with removing the threaded adapter or different loading conditions. However, they are not individually adjusted and conditioned to meet higher end load cells requirements.

For a more in-depth comparison, see our blog @ https://mhforce.com/load-cell-adapter-thread-depth-comparison/

Because of this, most adhere to the rule of engaging threads to at least their diameter. However, in practice, load cells can show significant variations in output depending on whether thread engagement is less or greater than recommended. Proper loading conditions are crucial for reducing measurement errors.

We have previously covered thread engagement by varying the thread depth of an adapter installed into the top-threaded portion of the load cell.

If an adapter is not purchased or installed into the load cell, Morehouse recommends discussing how your calibration laboratory calibrates such devices. The examples above show the drastic difference between adapters and loading conditions. The errors can be 20 times what might be expected. When this happens, significant global risk could be passed via the subsequent measurement, which is eventually passed to the consumer.

Figure 7 Morehouse Stainless Steel Budget Load Cell Shoulder Loading Errors are Low.

Morehouse Budget Shear Web Load Cell Summary

Advantages:

- They have very low creep and are less sensitive to off-axis loading than the other load cells.

- They are machined out of Stainless Steel and hold up well aesthetically.

- These load cells are a better choice if the top threaded adapter needs to be removed, as the errors are significantly less than the traditional shear web cells.

- Without the threaded adapter installed, as shown in the picture, errors from thread engagement can be 0.02 % or more.

- The load cell shoulder loading errors are less than many similar-type load cells.

Disadvantages:

- After 112,000 lbf, the cell's weight makes it exceedingly difficult to use as a reference standard in the field, as these cells are modified to have more material than a traditional shear web cell.

- Being budget load cells, they do not receive the extra labor that improves performance.

Load Cell Shoulder Loading Errors Conclusion:

The data and analysis for load cell shoulder loading presented in this article underscore the critical importance of proper loading conditions—specifically, shoulder loading and thread engagement—when using and calibrating load cells. While the Morehouse Budget Load Cell demonstrates robust performance, particularly with the threaded adapter installed, assumptions about negligible error without the adapter can lead to significant measurement discrepancies.

Even small deviations in loading configuration can produce errors that exceed acceptable tolerances, especially under more stringent calibration standards like ISO 376 or ASTM E74. These standards demand higher accuracy, and thus, calibration methods must mirror the actual use case to ensure the reliability of force measurements.

More Information about Morehouse

We believe in changing how people think about Force and Torque calibration in everything we do, including discussions on load cell shoulder loading errors.

This includes setting expectations and challenging the "just calibrate it" mentality by educating our customers on what matters and what may cause significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition, providing you with more accuracy and precision in force measurement.

We turn around your equipment in 7-10 business days so you can return to work quickly and save money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Through Great People, Great Leaders, and Great Equipment, we empower organizations to make Better Measurements that enhance quality, reduce risk, and drive innovation.

With over a century of experience, we're committed to raising industry standards, fostering collaboration, and delivering exceptional calibration solutions that build a safer, more accurate future.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff. We have many more topics other than load cell shoulder loading errors.

Our YouTube channel has videos on various force and torque calibration topics here.

# Load Cell Shoulder Loading