Load Cell Loading: Thread Engagement Errors

Morehouse has covered this topic in previous videos and blogs. However, it is important enough to write another blog about thread engagement. Why is it important?

In a typical female thread design, the modeling is done with “assumptions” on the thread engagement. A standard rule is to assume the engagement will be at least equal to the thread sizes.

In general, the first handful of threads provides maximum strength. Engaging beyond this first handful often yields diminishing returns.

Therefore, most people live by the rule of thumb of at least engaging the thread by the diameter of the thread. In many load cells, engaging less or more can produce significant changes in output. The loading conditions for almost any load cell are critical when minimizing the error.

Below are several tests conducted by Morehouse on various load cells showing the differences in loading conditions.

S-Beam example where loading through the threads versus against the base produces up to a 0.369 % difference in output.

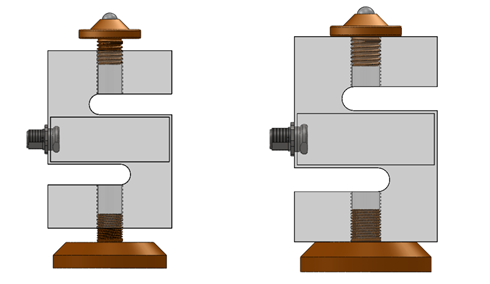

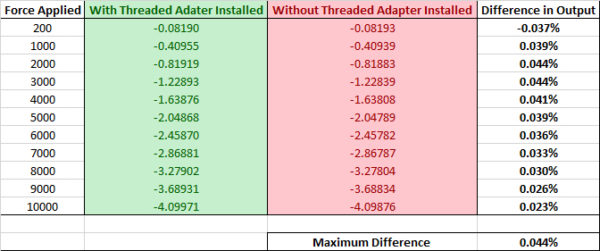

10,000 lbf shear-web example showing a maximum difference of 0.044 % with an integral adapter installed versus engaging about 0.625” of thread and loading on the shoulder.

This error can become more significant depending on the actual thread engagement. A standard rule of thumb is to engage at least the thread diameter. At 0.625” of engagement, we have observed errors as high as 0.2 % comparing three different calibration setups with an integral adapter and a non-shoulder loaded full engagement of over 1”.

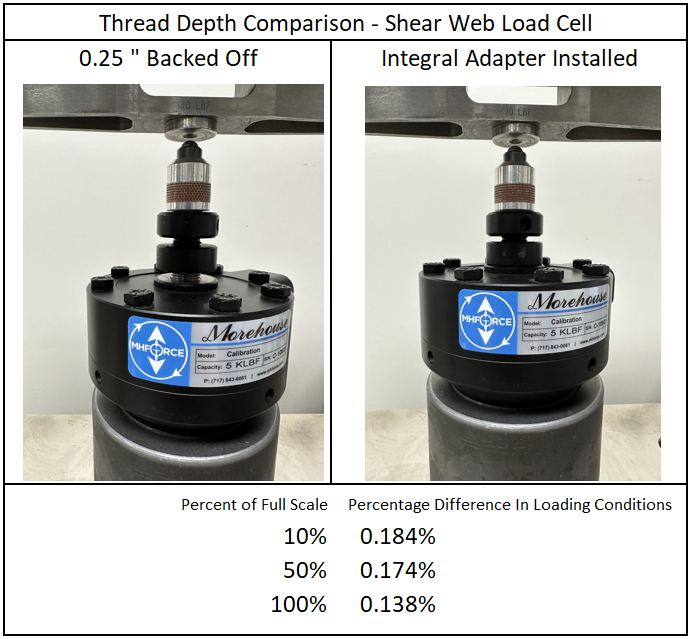

The picture above shows the difference between loading through the threads with about 0.8 " of threads (adapter backed off 0.25 ") and an integral adapter locked into place.

Below is another example of a 10,000 lbf load cell tested with two different adapters against the shoulder. The difference in output was 0.59 % using two adapters. One with 1.5” (10,001.5 lbf) of engagement and another with 0.5”(9,942.3 lbf) of engagement.

The error on this measurement was over 0.5 % on a device expected to be better than 0.025 % (20 times expected).

The best recommendation is to purchase and lock in an integral adapter, as many Morehouse shear web load cells come standard with an integral adapter. Other manufacturers sell similar load cells, though the adapter is an add-on and is often not purchased with the load cell. This often creates a significant disconnect between what the customer will use with the load cell and how it was calibrated.

If an adapter is not purchased or installed into the load cell, Morehouse recommends having discussions with your calibration laboratory about how they calibrate such devices. The examples above show the drastic difference between adapters and loading conditions. The errors can be 20 times what might be expected. When this happens, significant global risk could be passed via the subsequent measurement, which is eventually passed to the consumer.

Thread Engagement

Back to the general rule of thumb: if we do not know, we engage the thread by matching the diameter of the load cell. There are two effortless ways to do this.

- Measure the depth of the thread and put a line where the thread should stop. Electrical tape and thread tape can also work.

- Calculate the number of turns it would take to match the thread size.

The basic calculation is multiplying the number of threads per inch by the required engagement. Example 1: I have a ½”-20 thread and want 0.5” engagement. Since I have 20 threads per inch, I would divide 1/20. This gives me 0.05” of engagement per full turn. Then, take 0.5” / 0.05, which equals 10. Thus, for 0.5” of engagement on a ½”-20 thread, I would need to count 10 full turns.

Example 2: I have a 1 ½”-12 thread and want 1.5” of engagement. Since I have 12 threads per inch, I would divide 1/12. This gives me 0.083” of engagement per full turn. Then take 1.5” / 0.083, which equals 18. Thus, for 1.5” of engagement on a 1.5-12 thread, I would need to count 18 full turns.

Again, the best practice is to have an integral adapter locked into place. The next best solution is to purchase adapters, such as a load button from Morehouse (shown below), or supply adapters for use with the calibration. Be sure to explain thread engagement and how the adapters are used.

If no information is obtainable, we recommend reverting to this general rule of thumb: match the thread engagement with the diameter of the thread. We caution everyone to ensure their equipment is safe and designed so that this rule does not pose any safety hazards and that this amount of engagement does not damage the load cell.

Conclusion

Morehouse wants to help educate our customer base on what we do and how we do it. We are always looking to improve our capabilities and yours. Knowledge is power.

We hope this article has helped you understand the differences in measurement errors from engaging threads at different depths that do not align with how the item was calibrated. We urge everyone to consider installing integral adapters or purchasing adapters from Morehouse or wherever to pair with your equipment for calibration.

Please continue to check out our blogs and the Documents and Tools section of our website for information guaranteed to help you start making better measurements.

I take great pride in our knowledgeable team at Morehouse, who will work with you to find the right solution. We have been in business for over a century and focus on being the most recognized name in the force business. That vision comes from educating our customers on what matters most and having the proper discussions relating to force calibration basics so that everyone speaks the same language.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

We believe in changing how people think about force and torque calibration in everything we do. We challenge the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors and focus on reducing them.

In addition, Morehouse makes simple-to-use calibration products. We build fantastic force equipment that is plumb, level, square, rigid, and provide unparalleled calibration service with less than two-week lead times.

Contact us at 717-843-0081 to speak to a live person or email info@mhforce.com for more information.