In modern engineering, precise force measurement is a cornerstone of innovation and safety. Imagine the intricate dance of forces in a high-speed train or the delicate balance required in an aircraft's wing structure. These scenarios underscore the critical importance of accurately measuring forces to maintain the integrity and performance of engineering marvels.

Force measurement involves quantifying the push or pull exerted on an object. This process is essential across various industries, from aerospace to automotive and everyday manufacturing. Engineers can design robust and efficient components by understanding the forces at play and optimizing material use and energy consumption.

Safety is paramount in engineering, and accurate force measurement prevents structural failures and accidents. Ensuring that every component can withstand the forces it encounters protects both machinery and the people who rely on it. Moreover, force measurement aids in quality control, ensuring products meet stringent industry standards and perform as expected.

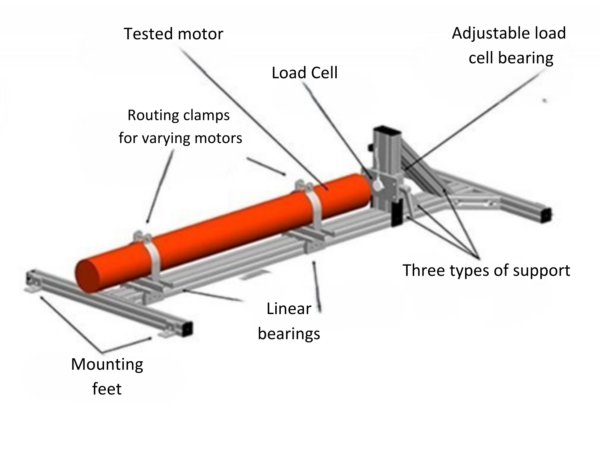

The technology behind force measurement has evolved significantly, paving the way for more accurate and reliable measurements. Advanced sensors and load cells can now convert mechanical force into precise data, providing engineers with invaluable insights for fine-tuning designs and processes. This evolution has led to greater accuracy and reliability in force measurement, enhancing the safety and efficiency of engineering practices.

Force calibration is a critical process that ensures the accuracy and reliability of force measurements. It often involves comparing an unknown measurement device to a relatively well-known standard and maintaining the precision of force measurement systems, a key aspect of engineering safety and efficiency.

Load cells, which convert mechanical force into electrical signals, play a central role in force measurement. Understanding the different types of load cells and their functionality is crucial for selecting the right one for specific applications. This understanding is a testament to the complexity of force measurement and the need for specialized knowledge in engineering.

Calculating measurement uncertainty is also essential, as it quantifies the doubt about a measurement result. Properly accounting for this uncertainty ensures that engineers can trust the data they collect and make informed decisions. A more in-depth read on how to make those decisions can be found in our decision rules guidance document. Download your free copy here.

Real-World Applications Highlighting the Importance of Force Measurement

Bridge and Infrastructure Safety: Bridge collapses and other infrastructure failures often highlight the critical need for accurate force measurement. For instance, when constructing a bridge, measuring the concrete's strength and ensuring that the steel and cables are tested for appropriate tension and compression is essential. Inaccurate force measurements can lead to catastrophic failures, as seen in past incidents where bridges have collapsed due to structural weaknesses.

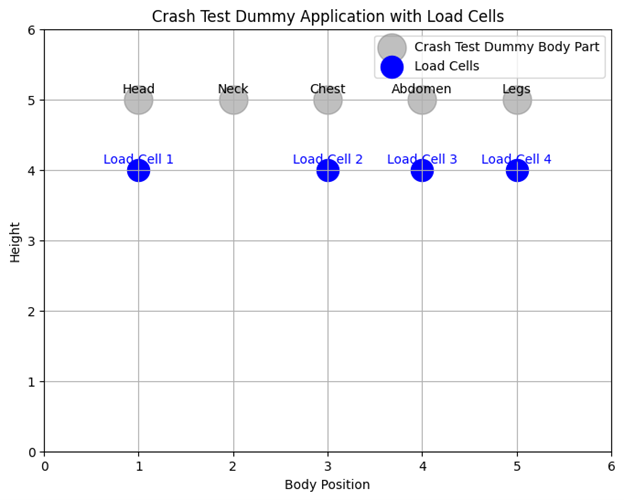

Automotive Industry: In the automotive sector, force measurement is crucial for testing the strength and durability of vehicle components. Force sensors are used in crash tests. Recent recalls and safety investigations often reveal that inadequate force testing can lead to component failures, compromising vehicle safety. Ensuring that parts can withstand operational forces is vital to prevent accidents and improve vehicle longevity.

Aerospace Applications: The aerospace industry relies heavily on precise force measurement to test aircraft parts under various stress conditions. Any failure to accurately measure these forces can lead to safety risks and operational inefficiencies. The rigorous testing of components like wings and fuselage sections ensures they can endure the forces encountered during flight. There is also the testing of the thrust of a rocket and many other examples where force-measuring instruments are needed.

Manufacturing and Quality Control: Force measurement is integral to quality control processes in manufacturing. Products ranging from electronic devices to heavy machinery are tested for durability and performance under specific force conditions. Even determining the force to remove the lid from a plastic package is tested. The testing helps ensure that industry standards are met and perform reliably in real-world applications. Failures in force measurement can lead to product recalls and reputational damage for manufacturers.

Force measurement is not just a technical necessity but a cornerstone of innovation in engineering. It supports creating safer, more efficient, higher-quality products, driving technological advancements across industries, and inspiring future innovations. For those looking to delve deeper into the world of force measurement, mhforce.com offers a comprehensive range of solutions to meet the most demanding engineering challenges.

Morehouse can provide load cells and other instruments to help meet many force measurement challenges in engineering.

For more information about force measurement or how Morehouse Instrument Company can assist you, email info@mhforce.com

About Morehouse Instrument Company

Companies worldwide rely on Morehouse for accuracy and speed. The company turns around equipment in 7-10 business days so customers can return to work quickly and save money.

The York, PA-based company provides force and torque measurement products and services worldwide.

Morehouse Instrument Company, a trusted and accredited provider of force and torque measurement services for over 100 years, offers measurement uncertainties 10-50 times lower than the competition.

Morehouse helps commercial labs, government labs, and other organizations lower their measurement risk by lowering equipment uncertainties for torque and force measurement. Contact Morehouse at info@mhforce.com .

More Information about Morehouse

We believe in changing how people think about force and torque calibration in everything we do.

This includes setting expectations on load cell reliability and challenging the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition.

We turn around your equipment in 7-10 business days so you can return to work quickly, saving you money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff.

Our YouTube channel has videos on various force and torque calibration topics here.