How Do Load Cells Work?

Load cells measure force by converting mechanical strain into an electrical signal using strain gauges. When a load is applied, the cell deforms slightly—this strain is detected by strain gauges bonded to the structure. The gauges change resistance as they stretch or compress, producing a signal proportional to the applied force.

Key Concepts Behind Load Cell Operation (How do Load Cells Work)

What Is Strain?

Strain is the deformation (stretch or compression) of a material relative to its original length.

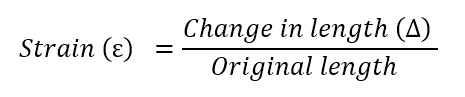

Strain is then defined as the change in length divided by the original length and is symbolized by the Greek letter ε (epsilon).

Mathematically:

-

Unitless (often written as mm/mm or in/in)

-

Strain gauges detect this tiny deformation

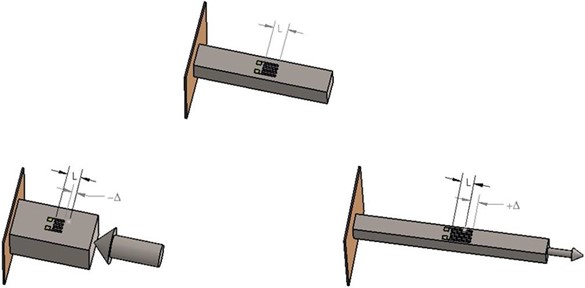

When we mount a strain gauge to a body, its length stretches or shrinks along with that body. It’s common to denote that increase or decrease with the Greek letter Delta (Δ ) , as shown below.

The figure above shows that Δ decreases when the material is pushed on and increases when the material is pulled on.

Typically, many load cells are wired so that a meter will read a negative value in compression and a positive value in tension.

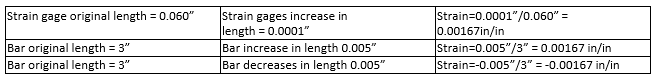

It is interesting to note in the above figure that the overall length of the bar changes more than the strain gages. However, they both experience the same strain. Adding numbers to the figure above when the length changes by 0.167 %, we get:

It’s also true that if we increase the length of the bar, it will stretch more, but the strain will be the same. This is true as long as the cross-section of the bar and the applied force remain the same. For example, if the bar started as 6” with the same force, then:

![]()

Example:

-

Original gauge length: 0.060”

-

Increase in length: 0.0001”

-

Strain = 0.0001 / 0.060 = 0.00167 in/in

What Is Stress?

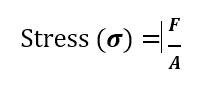

Stress is the internal resistance of a material to an applied force, measured as force per unit area.

Stress is defined as force per unit area and is typically measured in units of lb/in2 (psi) or N/m2 (Pa or Pascals).

Mathematically:

σ = Stress

F = Force Applied

A = Cross section area on the force is acting

Example:

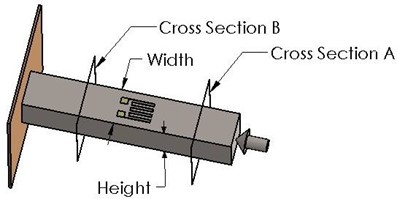

Given that the Height is 20 mm, the Width is 20 mm, and the compressive force is 100 Newton, we can calculate the stress at cross-section A.

σ =100N/(.02m*.02m) = 250,000 N/m2 =250,000 Pascals (Pa) = 0.25 MPa

We note that the cross-section area shown above is the same for “A” and “B”. Therefore, stress is also the same. But if the size of cross-section “B” is enlarged, the stress goes down in that area.

It’s no coincidence that pressure and stress are measured in the same units because they both describe force distributed over an area. The distinction between the two depends on the reference frame you use.

Pressure is typically defined as a force applied externally to a surface, acting perpendicular to the object’s boundary. It is often associated with gases and liquids, which exert pressure uniformly in all directions when in a contained system. For example, atmospheric pressure pushes on everything around us, and hydraulic pressure acts on the walls of a cylinder.

Stress, on the other hand, refers to internal forces within a material that resist deformation when an external force is applied. It describes how forces distribute inside a solid object, causing it to stretch, compress, or shear. Stress is crucial in engineering and material science, as it helps determine whether a material can withstand certain loads without failing.

Essentially, the key difference is that pressure is an external force per unit area, while stress is an internal force per unit area within a material. However, mathematically, both are expressed in units like Pascals (Pa), which is Newtons per square meter (N/m²). This similarity shows how interconnected these concepts are in physics and engineering.

Note: Stress and pressure share units but differ in context—pressure is external, stress is internal.

What Is the Modulus of Elasticity?

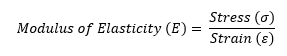

Modulus of Elasticity relates stress to strain and measures material stiffness.

Mathematically:

Since Strain is said to be dimensionless, the unit of E is the same as Stress. It’s common to report values as GigaPascals (GPa) or 106 PSI

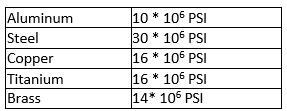

The Modulus of Elasticity for most materials is published by manufacturers. Here are some typical values:

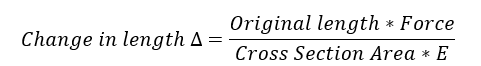

Upon rearranging, we see that if we know the force acting on a body and the Modulus of Elasticity, we can predict the stretching or shrinking of that body.

Typically:

-

Higher E = less deformation

-

Steel typically has 3× the stiffness of aluminum

We referred to strain as meaning “stretch”. We can likewise think of E as the “stretchability” of a material.

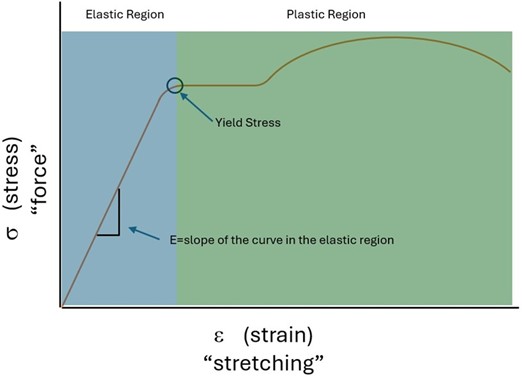

How do Load Cells Work: What Is the Stress-Strain Diagram?

The stress-strain graph shows how materials respond to force—first elastically, then plastically.

-

Elastic Region: Material returns to original shape

-

Plastic Region: Permanent deformation

-

Yield Stress: Stress level where plastic deformation begins

-

Young’s Modulus: Slope of the elastic region (stress ÷ strain)

Engineering Insight: Load cells operate within the elastic region—typically at <1/3 of yield stress to prevent permanent damage.

Engineers use the stress-strain diagram to quickly understand important aspects of material behavior. By plotting stress against strain, we can see how material behaves as forces increase.

The graph below, typical for most engineering metals, is divided into elastic and plastic regions. Elasticity is the property of a material that allows it to return to its original shape and size after removing an applied force. In the plastic region, the forces are so high that the material is permanently deformed when the forces are removed. Anyone who has played with a paperclip will already have some intuition of this behavior.

In this graph, we introduce the term ‘Yield Stress.’ This is the amount of stress in a material where only a very small amount of plastic deformation occurs. We usually limit rated capacity to less than 1/3 the Yield Stress for a load cell to operate correctly.

We also note that the Modulus of Elasticity only applies in the elastic region. By definition, it is the slope (Rise/Run or Stress/Strain) of the straight curve in this region.

| Concept | Definition | Formula | Units |

|---|---|---|---|

| Strain (ε) | Deformation per unit length | ΔL / L₀ | Unitless (in/in) |

| Stress (σ) | Force per area | F / A | Pa, psi |

| Modulus (E) | Stiffness = Stress ÷ Strain | σ / ε | GPa, psi |

How do Load Cells Work: Why It Matters

Understanding how load cells work is essential for:

-

Designing safe and accurate measurement systems

-

Selecting the right material and geometry

-

Operating within a load cell’s elastic range to maintain precision

More Information about Morehouse

We believe in changing how people think about Force and Torque calibration in everything we do, including discussions on how do load cells work.

This includes setting expectations and challenging the "just calibrate it" mentality by educating our customers on what matters and what may cause significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition, providing you with more accuracy and precision in force measurement.

We turn around your equipment in 7-10 business days so you can return to work quickly and save money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Through Great People, Great Leaders, and Great Equipment, we empower organizations to make Better Measurements that enhance quality, reduce risk, and drive innovation.

With over a century of experience, we're committed to raising industry standards, fostering collaboration, and delivering exceptional calibration solutions that build a safer, more accurate future.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff. We have many more topics other than expressing SI units!

Our YouTube channel has videos on various force and torque calibration topics here.

# How do Load Cells Work