How to Calibrate Cable Tensiometers: Addressing Error Sources and Promoting Standardization

Figure 1: Henry Zumbrun uses a Morehouse Cable Tensiometer Machine (PCM-2MD-T1).

How to Calibrate Cable Tensiometers: Introduction

Cable tensiometers are precision instruments used to measure cable tension in aerospace, industrial, and structural applications. Accurate calibration of these devices is essential to ensure reliable force readings—especially in mission-critical environments such as aircraft flight control systems.

Tensiometer calibration, however, is highly sensitive to several variables, including cable length, cable type, and calibration methodology. If these factors are not properly controlled, measurement deviations of up to ±20 % can occur, compromising both safety and performance.

This document identifies the most common sources of calibration error and establishes standardized best practices derived from current NAVAIR specifications, updated Navy METCAL methodologies, and relevant industry experience. It provides guidance for technicians and calibration laboratories responsible for certifying cable tensiometers used in aircraft maintenance and structural testing.

Common Error Sources

Figure 2: Comparing Different Length Cables.

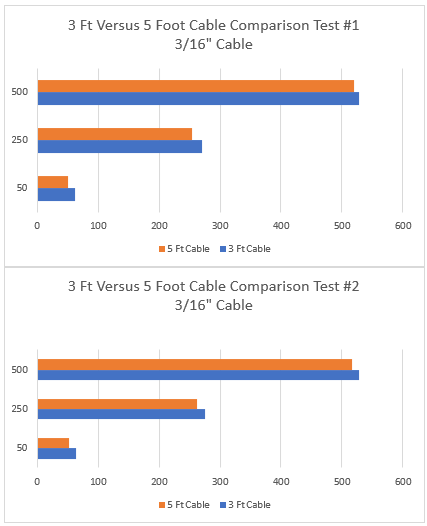

1. Cable Length Effects

Tensiometers work by applying a small offset to the cable, effectively increasing tension during measurement. This additional force—referred to as induced tension—is inversely proportional to the cable length. For instance, the same tensiometer that induces 8 lbf of tension on a 3-ft cable may induce only 2 lbf on a 12-ft cable.

Shorter cables are stiffer and more sensitive to displacement, resulting in larger relative changes in tension.

Note: Tests conducted on 3/16” SSAC cables under 50–500 lbf tension indicated induced-tension bias of 12–22% for 3-ft cables versus <5% for 12-ft cables.

Standardization Recommendation:

- Use cables ≥3 ft in length for calibration.

- Ensure calibration cable length approximates actual in-use conditions to minimize induced error.

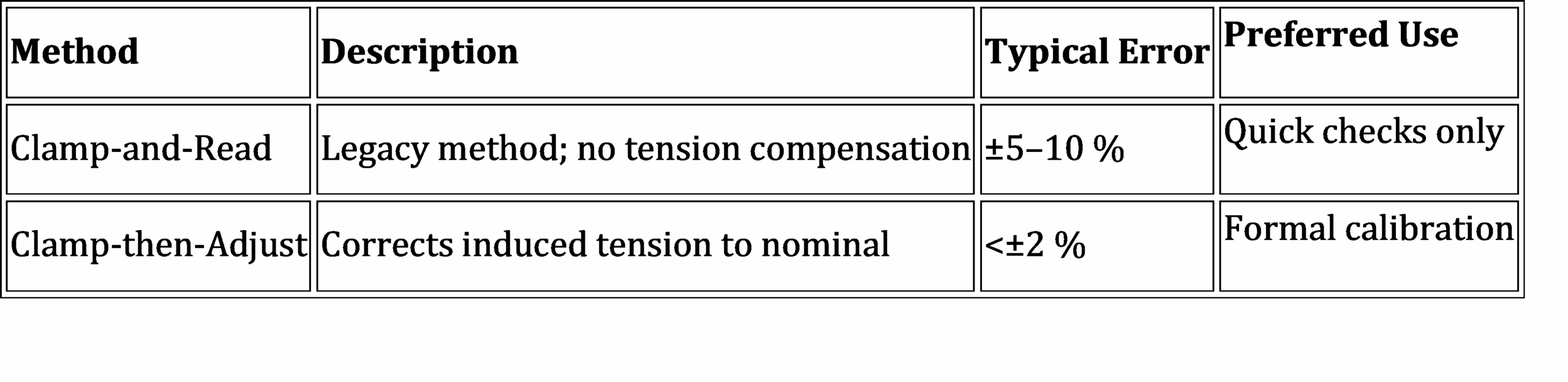

2. Calibration Methodology

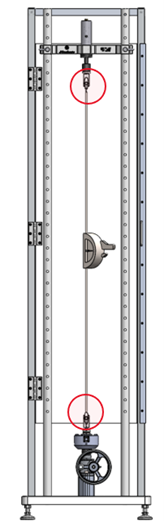

Figure 3: Cable Tensiometer Calibration Using Two Fixed Points

There are generally two primary approaches to tensiometer calibration:

- Clamp-and-read method (legacy): Calibrate by clamping the tensiometer onto a tensioned cable. This introduces additional tension but does not correct for it. (Example 500 lbf of cable tension may become 540 lbf when the tensiometer is clamped.)

Note: The reason this method would not be preferred is that it would eliminate calibrating cable tensiometers using deadweight.

- Clamp-then-adjust method (preferred): Clamp the tensiometer, observe the increase in tension, and adjust the applied force back to nominal. This simulates a deadweight calibration condition.

Standardization Recommendation:

- Adopt clamp-then-adjust as the preferred method to replicate deadweight equivalence and minimize offset bias. Align with revised NAVAIR 17-20MF-46 (post-2000) procedures that explicitly correct for clamping-induced tension.

3. Cable Type

Cable construction impacts tension response. For example:

- GAC (Galvanized Aircraft Cable) and SSAC (Stainless Steel Aircraft Cable) differ in modulus of elasticity and response to strain.

Standardization Recommendation:

- Always calibrate using the same cable type (GAC vs SSAC) that the instrument will be used with.

- If end-use cable types vary, produce separate calibration curves for each.

How to Calibrate Cable Tensiometers: Best Practices Checklist

The following checklist summarizes the standard calibration sequence for cable tensiometers:

- Inspection: Ensure the tensiometer is clean, free from damage, and set to zero with no load applied.

2. Cable Setup: Use the correct cable diameter and ensure it is free from defects (no kinks or broken strands).

3. Fixture Alignment: Ensure calibrator frame is level (the best rule of thumb is to use equipment that is plumb, level, square, rigid, and has low torsion).4. Clamp and Adjust: Apply known force, clamp the tensiometer, and adjust load to nominal if using dual fixed-point machines.

5. Repeatability: Conduct at least three repeat readings at each calibration point, ideally covering the low, mid, and high ends of the scale. - Maintain ambient temperature within ±2 °F of calibration standard conditions.

- Data Correction: Convert dial readings to force using calibration charts if using analog devices; compare with direct readings on digital models.

8. Documentation: Record calibration results, identify the method used, and affix calibration labels noting the cable type, cable length, and method.

Summary: This post recommends standardized calibration procedures to minimize induced-tension error, enhance repeatability, and ensure measurement traceability across varying cable lengths and types. Adopting these best practices promotes greater consistency and reliability in cable tensiometer performance across laboratories and field applications.

Frequently Asked Questions on How to Calibrate Cable Tensiometers (FAQ)

- How often should cable tensiometers be calibrated?

Tensiometers should be calibrated at least annually, or more frequently if they are subjected to heavy use, physical shock, or extreme environmental conditions.

- Can I use any cable type during calibration?

No. Always use the same cable type that the tensiometer will measure in service. Differences in construction and material properties can significantly affect calibration accuracy.

- Why is the clamp-then-adjust method preferred?

This method compensates for the extra tension added when clamping the instrument to the cable, replicating a true deadweight condition and ensuring more accurate results.

- What length of cable should I use when calibrating?

A minimum cable length of 3 feet is recommended to reduce induced-tension error. Longer cables more accurately simulate real-world use and yield more consistent readings.

- What environmental conditions affect calibration accuracy?

Temperature fluctuations greater than ±2 °F can cause material expansion or contraction, affecting tension readings. Perform calibrations in stable, controlled environments.

- Is calibration traceability required for aerospace applications?

Yes. Calibration should maintain traceability to the SI through an NMI such as NIST for aerospace and defense maintenance programs.

About Morehouse

We believe in changing how people think about Force and Torque calibration in everything we do, including discussions on how to calibrate cable tensiometers.

This includes setting expectations and challenging the "just calibrate it" mentality by educating our customers on what matters and what may cause significant errors.

We focus on reducing these errors and making our products simple and user-friendly.

This means your instruments will pass calibration more often and produce more precise measurements, giving you the confidence to focus on your business.

Companies around the globe rely on Morehouse for accuracy and speed.

Our measurement uncertainties are 10-50 times lower than the competition, providing you with more accuracy and precision in force measurement.

We turn around your equipment in 7-10 business days so you can return to work quickly and save money.

When you choose Morehouse, you're not just paying for a calibration service or a load cell.

You're investing in peace of mind, knowing your equipment is calibrated accurately and on time.

Through Great People, Great Leaders, and Great Equipment, we empower organizations to make Better Measurements that enhance quality, reduce risk, and drive innovation.

With over a century of experience, we're committed to raising industry standards, fostering collaboration, helping with understanding risk, and delivering exceptional calibration solutions that build a safer, more accurate future.

Contact Morehouse at info@mhforce.com to learn more about our calibration services and load cell products.

Email us if you ever want to chat or have questions about a blog.

We love talking about this stuff. We have many more topics other than expressing SI units!

Our YouTube channel has videos on various force and torque calibration topics here.

# how to calibrate cable tensiometers