3 Ways to Prevent Damage to Your Force Calibration Equipment

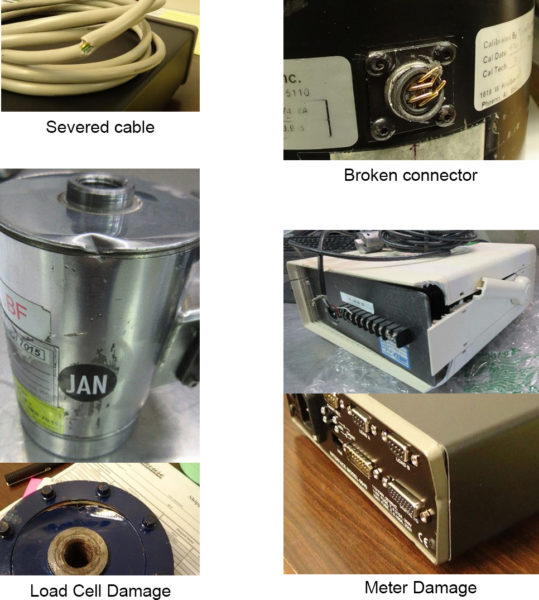

The purchase of force calibration equipment coupled with the calibration cost can be a large investment. Good, quality equipment provides a steady return on your investment for many years. Unfortunately, we see a lot of equipment damage such as broken connectors, severed cables, damaged load cell threads, damaged meters, broken dial faces, water damage, broken cases, nicks, and dings.

Figure 1: Typical force calibration equipment damage

If your equipment is damaged, the replacement cost for a connector starts at $150, damaged thread repairs start at $200, replacing a meter starts at $1,000, and replacing a load cell start at $1,000, but varies wildly depending on capacity and class of instrument. In addition to costly repairs, some damage results in a loss of traceability, which is important in the world of ASTM-E74 calibrations.

So how can you protect your investment from an early demise? Here are 3 practical ways to safeguard your valuable equipment from damage.

#1: Protocols for Handling and Packaging Equipment

Force-measuring equipment can be very heavy. Even a small load cell is often heavier than it looks. If this heavy equipment is dropped, jostled, or hits another piece of equipment, the resulting damage can be costly.

To train your technicians on how to properly handle and pack equipment, create job instructions. Include considerations on the weight of the equipment, fragile indicators, and how to separate heavier objects within a package.

Using a connector protector is another good option for extra protection. It will help safeguard the connector because it will take the hit rather than the pins, as shown below. If the load cells connector had taken the hit, there would be nothing left but sheared pins.

Figure 2: Connector protector safeguards the load cell pins

Choosing the right packing material is essential for keeping the equipment safe during shipment. Using cloth as a packing material is not recommended. For heavy equipment like the example below, a 2x4 barrier between the load cells would do a much better job of keeping them from banging into each other.

Figure 3: Load cell packed with cloth

Bubble wrap is a common packing material for fragile items. It may work well for a small, light object but not for an object 15 lbs. or more. Bubble wrap is not the best option for protecting heavy instruments. Bubble bags or peanuts also do not work well.

Figure 4: Load cell packed with bubble wrap

Cardboard boxes also have their limitations. The durability of the box should always be evaluated for the equipment it will hold.

Figure 5: Example of a cardboard box that did not hold up well

Shipping damages can always happen no matter how well something is packed, so be mindful of the packing material. Pack wisely, and if there is any doubt about whether your equipment will make it to its destination safely, then pack it better.

#2: Protective Shipping Case with Custom Cut Foam

A protective case is an excellent solution to protect equipment during shipment. There are a variety of options for cases with wheels, handles, latches, break-away foam, custom-cut foam, and dividers. The upfront cost of a case is much better than the unknown future cost of equipment repair or replacement.

Figure 6: Protective case for force calibration equipment

However, we do receive damaged equipment in cases because the breakaway foam was worn out or the equipment was not properly set up in the case. The weight of an instrument can destroy the breakaway foam.

Figure 7: Broken, worn-out foam pieces lead to damaged equipment

Custom foam that is properly cut, with holes for the instruments that are snug, but not too tight is best. When the holes are too tight, the foam just rips apart. When the holes are too loose, the instruments can jostle around, wearing the foam out faster and potentially damaging the equipment. Individual holes for each piece are recommended, but not necessary for some items, such as cables.

At Morehouse, we can fit your precious instruments into rugged instrument cases with custom-cut foam for a perfect fit. This means less worry about damage during shipping and handling.

Figure 8: Morehouse custom foam cases

We also can provide custom-cut foam for existing cases to securely fit your instruments. The cost of a case re-foam is dependent on the case size and complexity. A simple case re-foam will be around $170. This is a one-time cost, which should prevent future shipping damage. If you have already experienced several repairs due to shipping, then a case with good foam could have saved you money.

Figure 9: Force calibration equipment in original case and Morehouse case

Our cases have proven over time to cut down 99 % of the damage during shipment. We do see cases with broken latches and where the outside looks like a belt sander was taken to it, but the equipment is safe.

When cases become worn out or repurposed, they should be re-foamed or re-utilized to best protect the equipment inside it.

#3: Well-built Crate

For larger or heavier equipment, a box or protective case may not be robust enough to withstand the demands of shipment. A durable wooden crate will provide more protection.

A well-built crate will have the weight centered, as shown below.

Figure 10: Crate with load cells centered

Individual cubbies for each load cell are also smart when shipping large or heavy instrumentation.

Figure 11: Crate with individual space for each load cell

Even crates can get damaged, but the crate can be fixed, and it has served the purpose of protecting your equipment.

Figure 12: Damaged crates

Follow these three tips and you will provide longevity for your valuable force calibration equipment.

3 Ways to Prevent Damage to Your Force Calibration Equipment - Conclusion

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

# Force Calibration Equipment