The Importance of Torque Control

At the beginning of the year, we discussed the proper way to express torque units. This blog is going to discuss the importance of torque control.

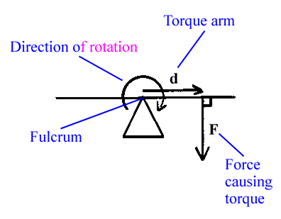

Torque = Force x Length this means the expression of lbf in or N m is the correct way to express torque. Those manufacturers calling something in lbf are wrong. In lbf is energy; it is not torque as we know and understand it.

Loosely speaking torque is the measure of the force required to turn an object such as a bolt or flywheel. For example, pushing or pulling the handle of a wrench or bolt produces a torque (turning force) that loosens or tightens it.

Why is torque Important?

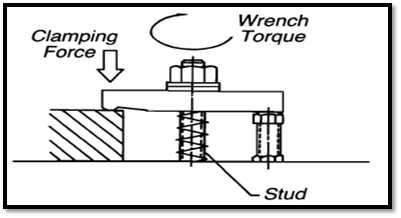

The object of a threaded fastener is to clamp parts together with a tension greater than the external forces tending to separate them. The reliability of the fastener depends on how well the tightening torque is controlled.

When torqued properly, the bolt remains under constant stress and is immune from fatigue. When the technician does not get the torque right or does something stupid like use WD40 to get the bolt to turn, BAD THINGS HAPPEN! What kind of bad things you ask?

The Importance of Torque Control - If the torque is not applied properly and the tension on the bolt torque is too low, varying loads will act upon the bolt, and it will fail.

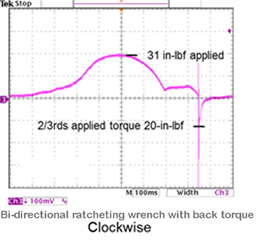

The picture above shows an H20 pump pulley bolt coming undone. This is common in Industry as those super-duper cheap wrenches your company may be using on the assembly line are not very good at getting the torque right. Most of them store so much energy that upon the initial click, the energy is released and a “back-torque” is applied. In some cases, this “back-torque” can be as high as 33 % of the initial torque. So instead of applying 30 lbf in of torque, only 20 lbf in gets applied. And what do you think happens to all the equipment out there with only 66 % of the appropriate torque applied?

Why do you think things fail? Does anyone ever report loose bolt failure? Well, the car manufacturers do. If you search for it, you will find it. How about those manufacturing missiles, rockets, or space-related things? Do they have a clue? Well, fortunately, some of them do, and one particular company exposed a situation that could have been catastrophic.

They developed a way to test for “back-torque”. Pictured below is a graph showing a Bi-directional ratcheting wrench with back-torque. This picture shows the wrench applying 31 lbf in and then 20 lbf in of back-torque. The result is only 11 lbf in of torque has actually been applied. This can lead to major product failures. Be sure to do your research and buy the proper wrenches for your application.

Did you hear the wrench “click”? Not sure? Why not apply the proper torque and let it click a few more times? – WHAT NOT TO DO (AKA OVER-TORQUING). Over-torquing is fine, but that’s a different blog unrelated to the Importance of Torque Control. That's one more on knowing the sometimes hidden torque errors.

If the tension is too high, the tightening process may cause bolt failure.

The Importance of Torque Control - Pictured Above: Metal snap from Jeff Nihel’s dragster, apparently, the bolts on the left exhaust manifold were over-torqued, and bolts then failed, the manifold popped off, and 4000bhp of exhaust gas launched the car in the air at over 200mph! Apparently, someone didn’t get their impact wrenches calibrated properly!

The Importance of Torque Control - Conclusion

There you have it: the importance of controlling the tightening torque. Proper torque calibration requires measurement traceability back to the calibration provider who calibrates the torque cell that calibrates the wrenches. In the UNITED STATES, no one has a traceable torque measurement chain back to SI Units through NIST.

Look it up. Go to bipm.org and find out that NIST does not offer torque calibration. Luckily, we know of one company that can calibrate your torque cells: one that bought a super-duper, highly accurate torque machine from NPL. We hear it’s the second most accurate torque machine in the world and it’s located in York, Pennsylvania. If you are ever in our area, there is an open invitation to visit. We may even give you a free T-shirt. If you are not coming by anytime soon, we welcome the opportunity to calibrate your torque cells and help you start making better torque measurements! Please contact us at sales@mhforce.com for more details.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

#The Importance of Torque Control