Calibration and Measurement Capability (CMC) Force Workbook- ASTM E74 Uncertainty

Morehouse has developed a force workbook in Excel to help those trying to figure out measurement uncertainty and how to calculate their Calibration and Measurement Capability (CMC). Updated 10/30/2021! The new update contains coefficients for interpolating uncertainty.

Most of this workbook is set up for labs following the ASTM E74 standard. (With slight modification the uncertainty sheet could be used for instruments calibrated in accordance with another test method or standard).

This Excel workbook can be downloaded here. There are several tabs in this workbook to help with the following:

ASTM E74 Calibration and Measurement Capability (CMC) worksheet

Repeatability and Reproducibility (R & R) worksheet

ILC to Calculate En Ratios - This can be used to satisfy ISO 17025 section 5.9 b.

Resolution Calculator - This can be used to calculate resolution for one to several points

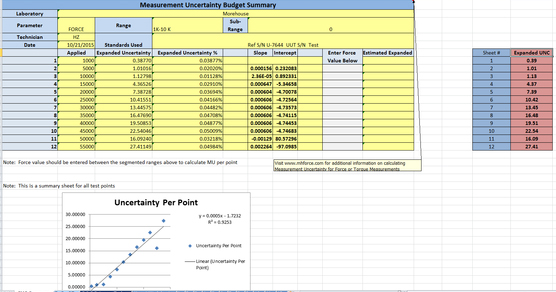

CMC Summary Worksheet - This uses a slope equation to interpolate expanded uncertainty (U) for any point within the loading range.

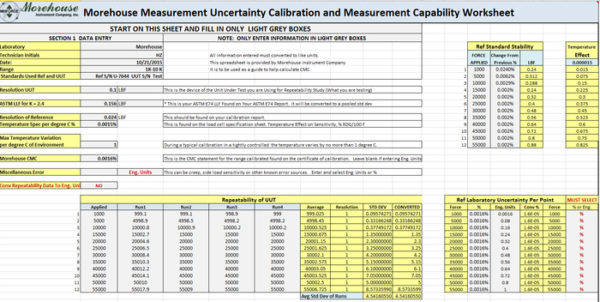

SECTION 1 DATA ENTRY

Section 1 Data entry: In this section enter the information about the standard being used.

Step 1:

Enter information about the calibration standard:

Resolution of the calibration standard

ASTM LLF - This is found on the calibration report. Note: if you are not using ASTM E74, this sheet has been updated to accept non-linearity and hysteresis.

Environmental Factors - For load cells enter max temperature variation. This is found on the specification sheet under Temperature - Effect on Sensitivity, % reading/degrees.

The CMC of the Reference Laboratory that calibrated the force measuring instrument - This gets entered in Ref Laboratory Uncertainty Per Point. The user must select if this is % or Eng. Units.

Reference Standard Stability - You will need to have two calibrations performed at different times to characterize the Reference Standard Stability.

Miscellaneous Error sources, if known - Side load sensitivity is a common error source

Note: Make sure everything entered is in like units.

Step 2:

Do a repeatability study using a test artifact. - We strongly recommend using an Ultra-Precision Load Cell that is very stable and repeatable as not doing so will have a negative impact on the CMC. We suggest purchasing an artifact that can also be used for SPC testing as this will strengthen the measurement assurance process.

Resolution of the artifact. - The lower the resolution, the better. (Resolution must be stable)

Next conduct repeatability tests on the artifact. - The repeatability study on this worksheet is set up for 3 or 4 test points. We suggest exercising the artifact and performing 4 runs of tests and recording the artifact output at each test point. The worksheet provides for up to 12 different test points. When testing repeatability, moving or rotating the artifact is not required.

Step 3 :

Enter the data for the artifact under the Repeatability of UUT. If data is in engineering units LBF, KGF, or N then set CONV Repeatability Data to Eng, Units on NO. If working in DIV, mV/V, or other non-engineering units, set CONV Repeatability Data to Eng. Units to YES.

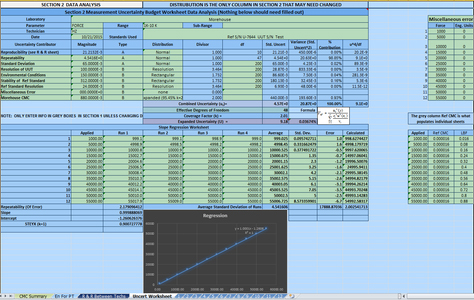

SECTION 2 DATA ANALYSIS

Section 2 Data Analysis:

In this section, it may be necessary to select the appropriate distribution.

Once everything is selected, the uncertainty per test point will be determined on each test point.

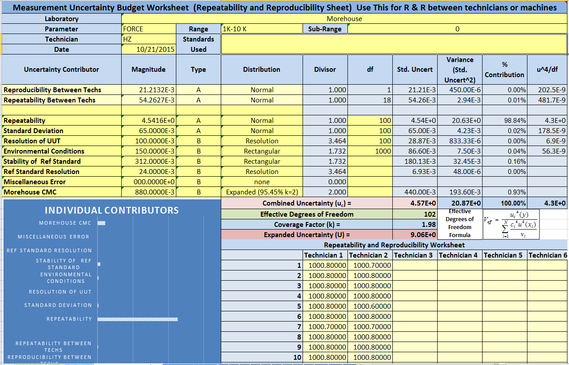

R & R Sheet

This sheet is used to do Repeatability and Reproducibility between technicians, between machines, or between different instruments. It is set up to be used as R & R between technicians if using multiple technicians.

Per ISO 5725 the general term for variability between repeated measurements is precision. Two conditions of precision termed repeatability and reproducibility conditions, have been found necessary and, for many practical cases, useful for describing the variability of a measurement method under repeatability conditions

This form will be populated with information found in the Data Entry Sheet. For this sheet, data can be entered for up to 6 technicians. The technicians should measure the same test point up to 10 times each and the reduced data should be entered under the Technician cells in light yellow.

CMC Summary Sheet

After all, data has been entered this worksheet will graph and calculate the uncertainty per test point.

This worksheet calculates the measurement uncertainty between test points.

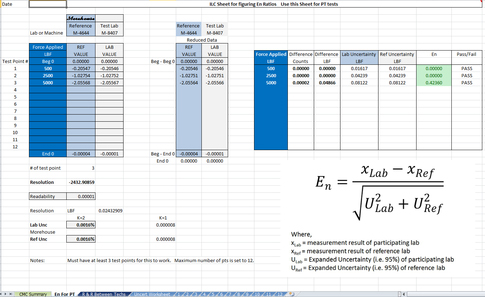

Does the Accreditation Body (AB) require Proficiency Testing (PT)?

The En for PT sheet is designed to help meet this requirement.

We strongly recommend using an Ultra-Precision Load Cell that is very stable and repeatable when used with a higher-end meter. Not doing so will have a negative impact on the CMC. This load cell can double as an artifact used for SPC testing and will strengthen the measurement assurance process.

To meet PT requirements, have this artifact calibrated by deadweight primary standards. Enter the calibration data for this artifact in the Ref Value Cells and enter the calibration data for the same artifact when calibrated by comparison with a secondary standard (reference load cell). Enter the Lab Unc (CMC) against the Ref Unc (CMC) and the sheet will calculate the En ratio and indicate a "pass" or a "fail".

Per ISO 17025 Section 5.9 Assuring the quality of test and calibration results

5.9.1 The laboratory shall have quality control procedures for monitoring the validity of tests and calibrations undertaken. The resulting data shall be recorded in such a way that trends are detectable and where practicable, statistical techniques shall be applied to the reviewing of the results. This monitoring shall be planned and reviewed and may include, but not be limited to, the following:

- a) regular use of certified reference materials and/or internal quality control using secondary reference materials;

- b) participation in interlaboratory comparison or proficiency-testing programs;

- c) replicate tests or calibrations using the same or different methods;

- d) retesting or recalibration of retained items;

- e) correlation of results for different characteristics of an item.

NOTE: The selected methods should be appropriate for the type and volume of the work undertaken.

ISO/IEC 17025 Accredited Calibrations.

The International Laboratory Accreditation Cooperation (ILAC) P-14 section 6.4 requires contributions such as the resolution of the Unit Under Test (UUT) be included in the uncertainty per point value reported on the certificate of calibration. Euramet CG4 v2.0 Uncertainty of Force Measurements also requires the resolution of both the standard and unit under test be reported as standard contributors. The per-point analysis consists of the UUT resolution and the CMC of our standard (which includes the resolution of the reference standard if primary standards were not used). When a full uncertainty analysis per ILAC P-14 is performed, as required by ISO/IEC 17025, the CMC (Calibration and Measurement Capability) is derived and reported to the user. There is a tab in this worksheet to help with calculating the CMC per point.

Morehouse can provide guidance on using this workbook. It is recommended a professional consultant be contacted if you are having problems figuring out CMC or what to report. We offer training with a focus on measurement uncertainty with an independent consultant (Dilip Shah of E=mc3 solutions) two to three times per year.

Once again, the workbook can be downloaded at http://www.mhforce.com/Files/Support/249/CMC-CALCULATIONS-FOR-FORCE-MEASUREMENTS.xlsx.

If you enjoyed this article, check out our LinkedIn and YouTube channel for more helpful posts and videos.

Everything we do, we believe in changing how people think about force and torque calibration. Morehouse believes in thinking differently about force and torque calibration and equipment. We challenge the "just calibrate it" mentality by educating our customers on what matters and what causes significant errors, and focus on reducing them.

Morehouse makes our products simple to use and user-friendly. And we happen to make great force equipment and provide unparalleled calibration services.

Wanna do business with a company that focuses on what matters most? Email us at info@mhforce.com.

# Force Workbook